A silicon grease applicator for light source boards for photovoltaic street lamp production

A technology of board silicone grease and applicator, which is applied in the direction of coating and liquid coating device on the surface, etc., which can solve the problems of time-consuming thermal conductive silicone grease, uneven silicone grease, waste of thermal conductive silicone grease, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

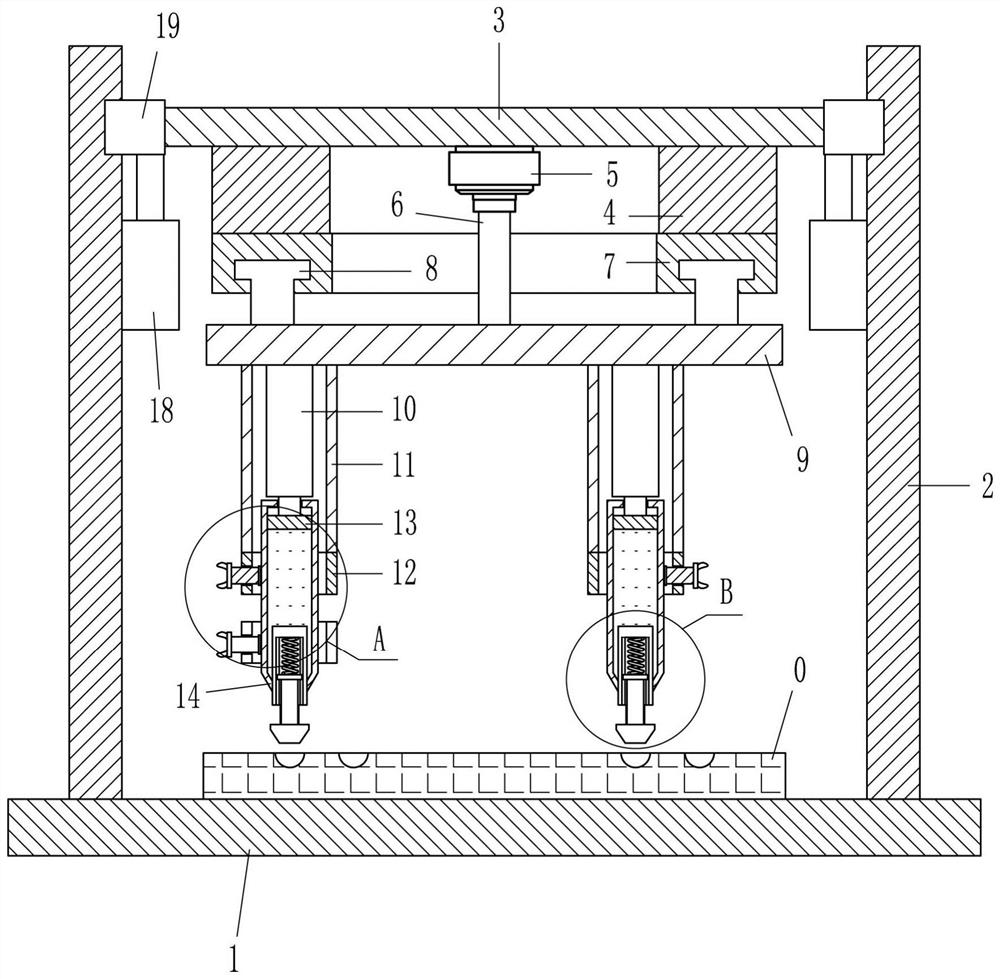

[0024] A silicon grease applicator for light source boards for photovoltaic street lamp production, such as Figure 1-8 As shown, it includes a mounting plate 1, a supporting slide rail 2, a load bearing plate 3, a supporting frame 4, a motor 5, a first rotating shaft 6, an annular slide rail 7, an annular slider 8, a turntable 9, a first electric push rod 10, Connecting frame 11, first installation ring 12, piston 13, silicone grease cylinder 14, first butterfly bolt 16, first rubber pad 17, second electric push rod 18 and support slider 19; two support slide rails 2 are fixed in sequence connected to the top surface of the installation board 1; the light source board 0 is placed on the top surface of the installation board 1; the second electric push rod 18 is fixedly connected to the side of the slide rail; the supporting slider 19 is connected to the output end of the second electric push rod 18 by transmission, and It is slidingly connected with the support slide rail 2; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com