Dual-rotation coating production stirring equipment

A mixing equipment and double-rotation technology, which is applied in the field of double-rotation paint production mixing equipment, can solve the problems of low stirring speed, poor fluidity, and high viscosity on the side wall of the tank, and achieve sufficient and efficient mixing, good mixing effect, and guaranteed quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

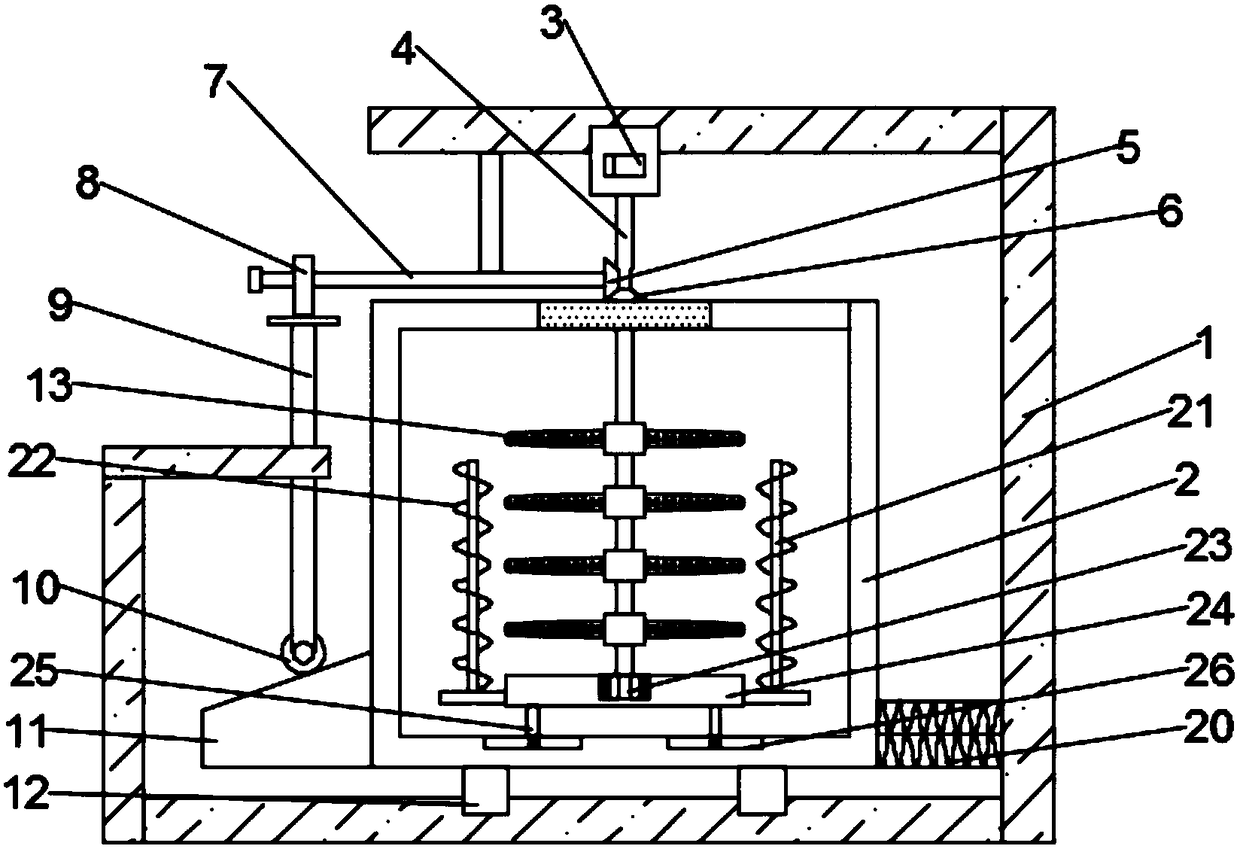

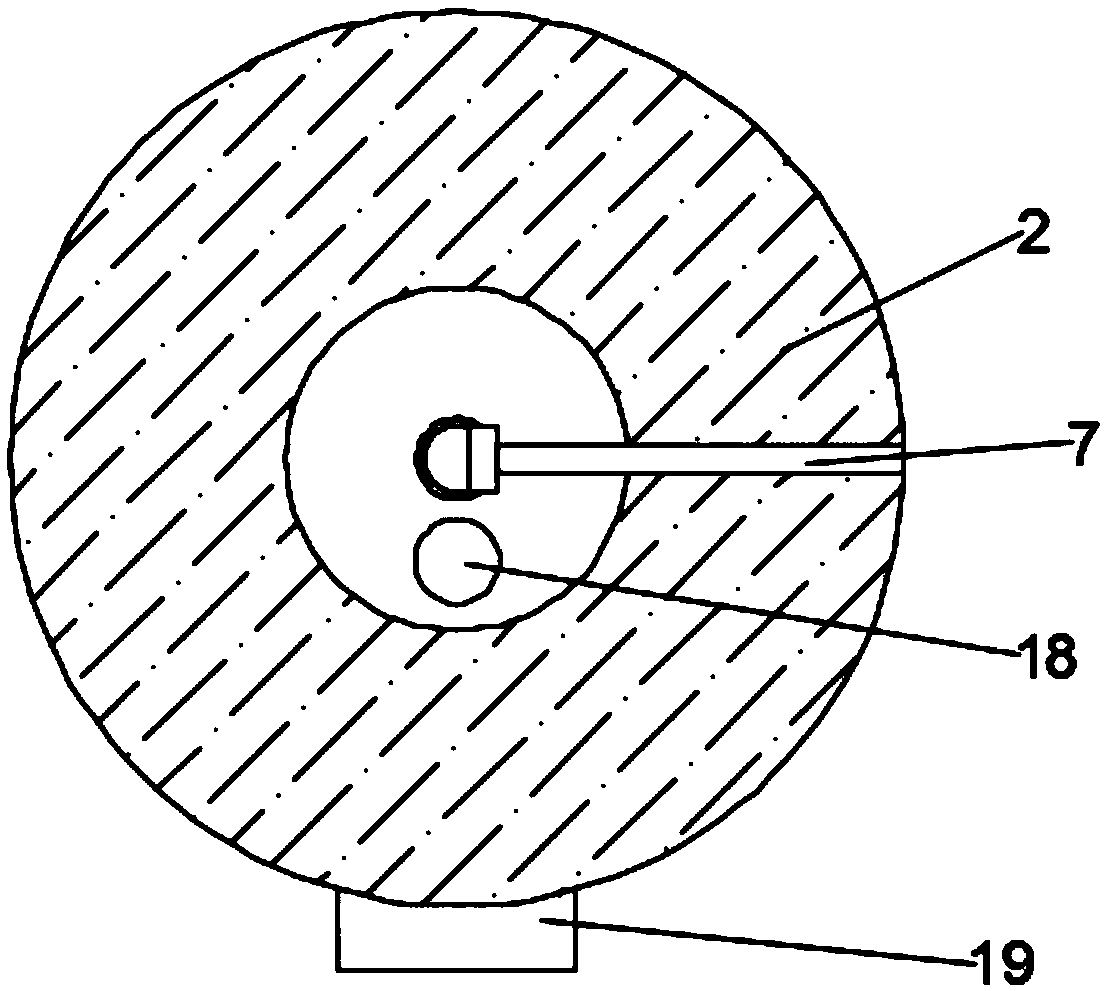

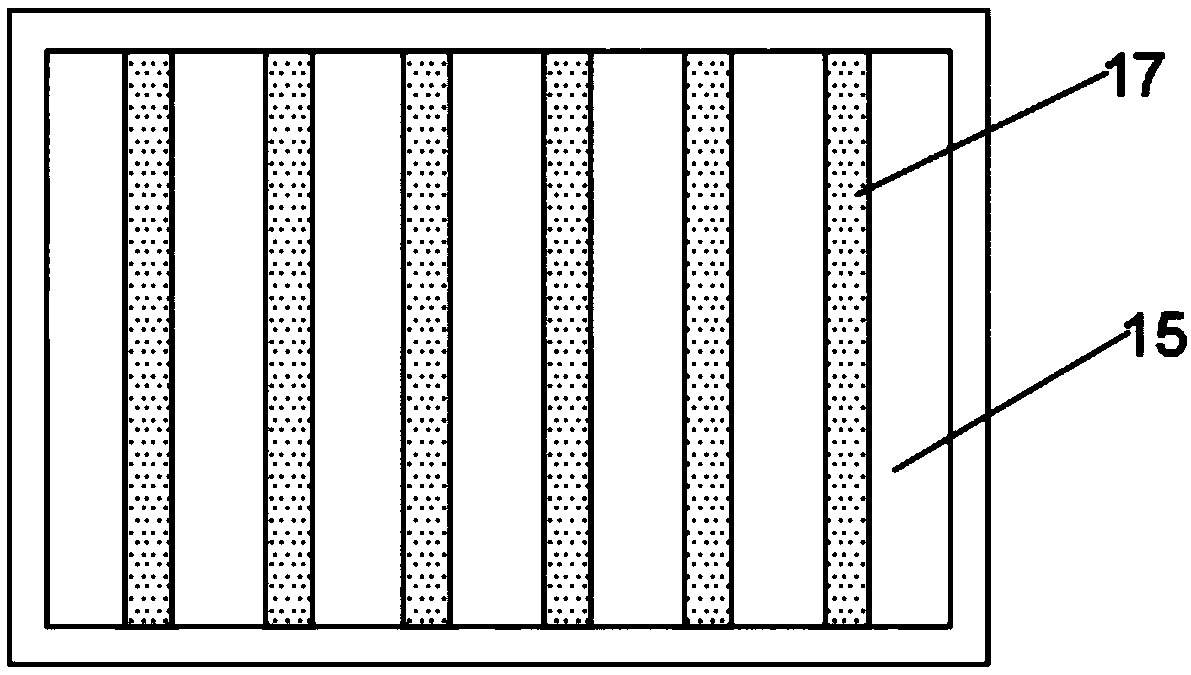

[0020] see Figure 1~4 , in an embodiment of the present invention, a double-rotation paint production stirring equipment, including a support frame 1, a stirring tank 2, a working motor 3, an inclined abutment plate 11 and a horizontal stirring assembly 13, the support frame 1 is provided with a sliding stirring tank inside 2. Both sides of the lower surface of the stirring tank 2 are symmetrically welded with sliders 12, the sliders 12 are slidably connected to the lower surface of the support frame 1, and the bottom of the left side wall of the stirring tank 2 is welded with an inclined abutment plate 11, the The left side of the inclined abutment plate 11 is inclined to be lower and the right side is higher, and a return spring 20 is arranged between the bottom of the right side wall of the first bevel gear 5 and the support frame 1, and the setting of the return spring 20 can realize The function of the buffer protection of the stirring tank 2; the horizontal stirring ass...

Embodiment 2

[0027] Such as Figure 5 As shown, in this embodiment, the cam 8 is replaced by a drive turntable 27, the left side wall of the drive turntable 27 is hinged to the push rod 9, and the hinge point of the push rod 9 and the drive turntable 27 deviates from the At the eccentric position of the drive turntable 27; compared with Embodiment 1, in this embodiment, the drive turntable 27 and the push rod 9 are hinged, which can ensure the consistency of the movement of the push rod 9 and the drive turntable 27, and avoid the pushing The rod 9 and the roller 10 slide off from the inclined abutting plate 11, thereby ensuring the fast and correct stirring. Compared with the first embodiment, the other structures of this embodiment are the same.

[0028]The working principle of the present invention is: paint enters the inner cavity of the mixing tank 2 through the feed port 18, starts the working motor 3, the working motor 3 rotates forward and reverse, and the rotation of the first rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com