Photoelectric coupler lead frame limiting support

A technology of optocoupler and lead frame, applied in the direction of electric solid devices, circuits, electrical components, etc., can solve the problems of rust steel plate positioning dead, poor conductivity, etc., to increase conductivity, improve plating uniformity, avoid derailment or Effects of crush damage or greater friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

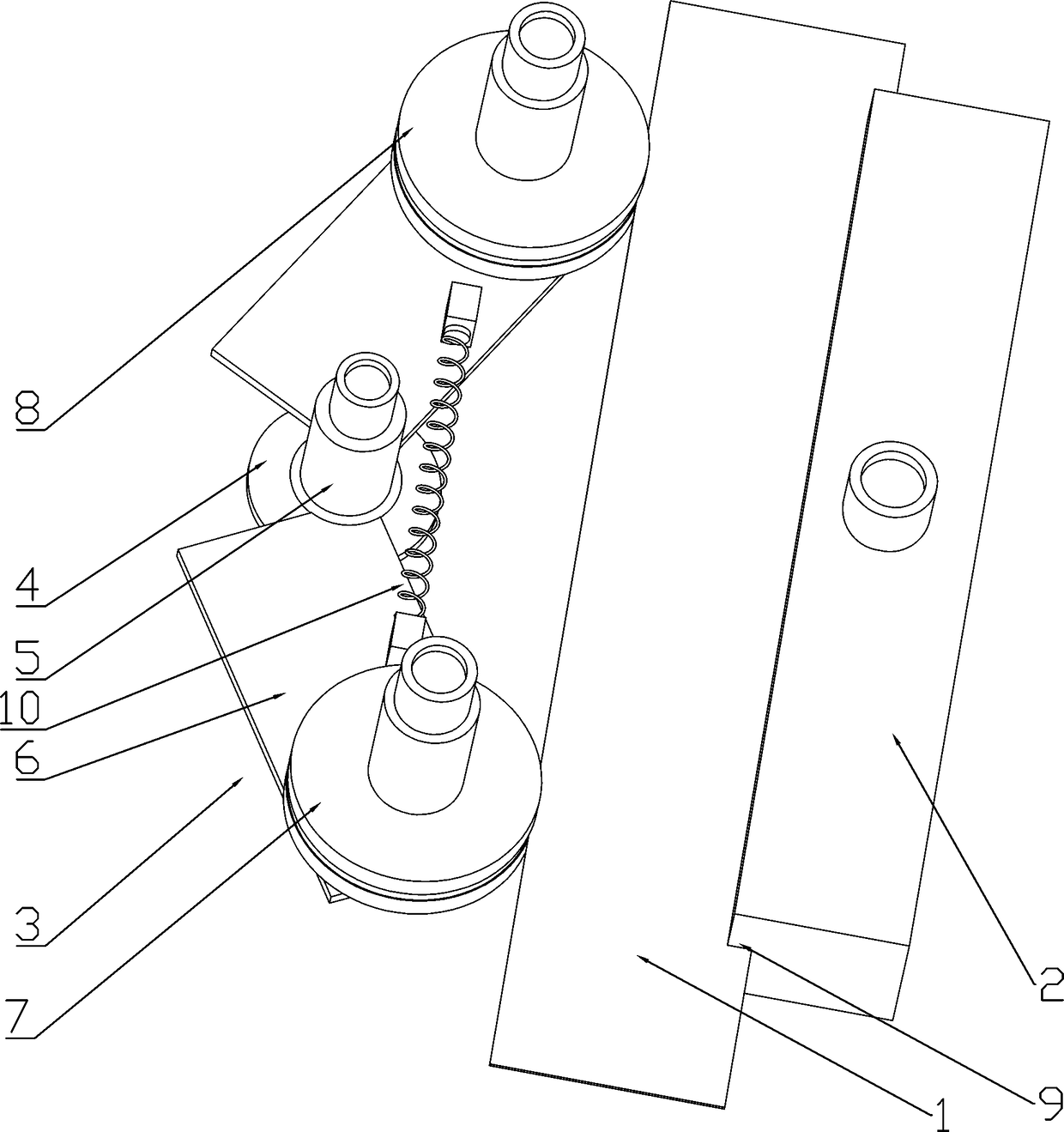

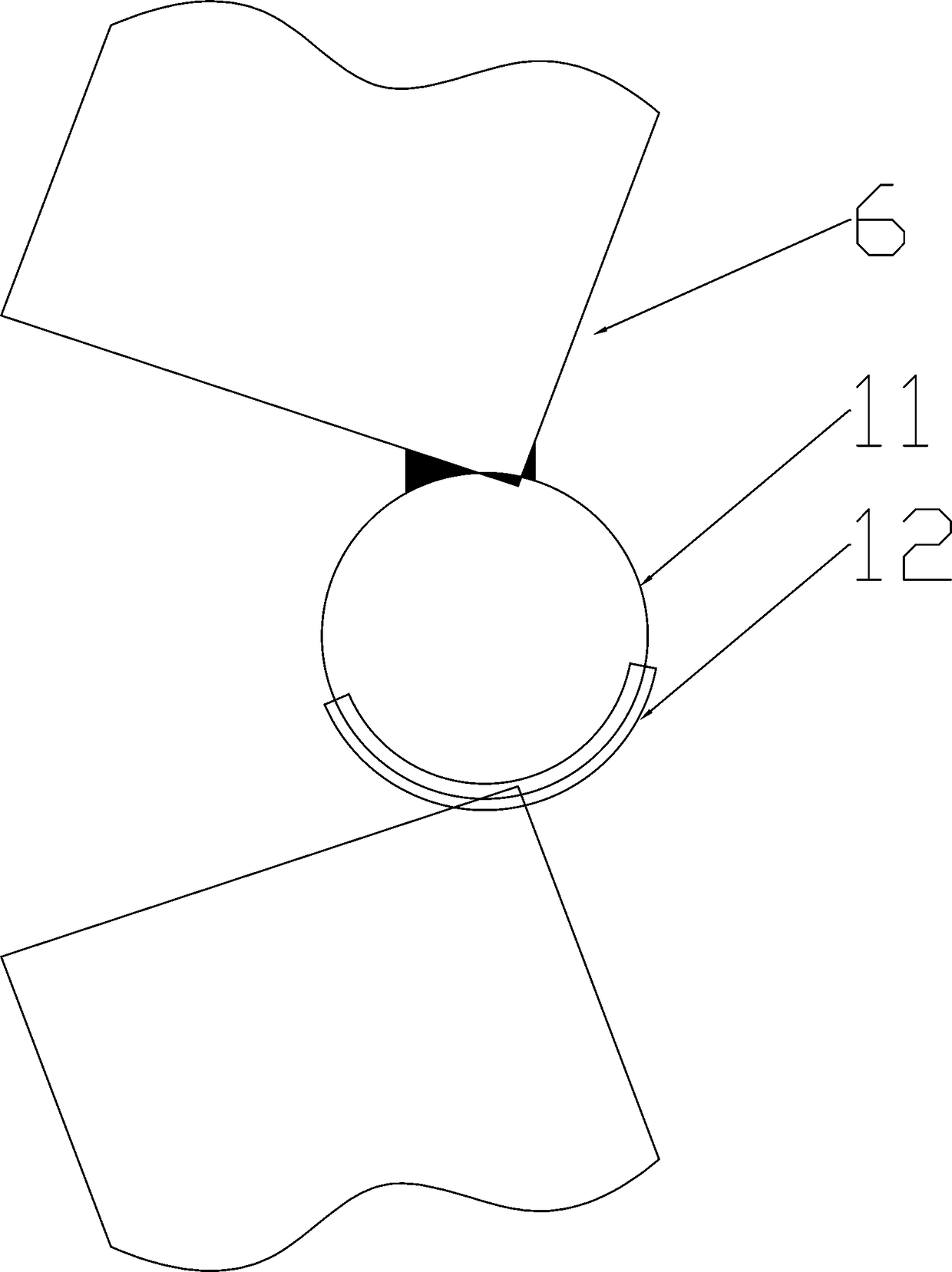

[0013] Such as Figure 1-2 As shown, a photocoupler lead frame limit bracket includes a positioning slide plate 2 arranged on one side of the photocoupler lead frame 1, the positioning slide plate 2 is made of copper, and a positioning chute 9 is opened on one side, and the positioning chute 9 is coated with a wear-resistant layer, and an adjustable sliding mechanism 3 is provided on the other side of the photocoupler lead frame 1, and the adjustable sliding mechanism 3 is made of stainless steel. The adjustable sliding mechanism 3 includes a fixed base 4, the fixed base 4 is provided with a rotating shaft 5, the rotating shaft 5 is provided with a ring groove, the arc sleeve 12 is arranged in the ring groove, and the arc sleeve 12 is socketed with the ring 11, It can rotate around the rotating shaft 5, and two positioning plates 6 are respectively connected to the edges of the arc sleeve 12 and the ring 11. The two positioning plates 6 are connected by a spring 10 and form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com