A test method for heat generation rate of power battery

A power battery and testing method technology, which is applied in the direction of measuring electricity, measuring devices, and measuring electrical variables, etc., can solve the problems of cumbersome testing process and lack of universal applicability, and achieve short test cycle, few test parameters, and reduced errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

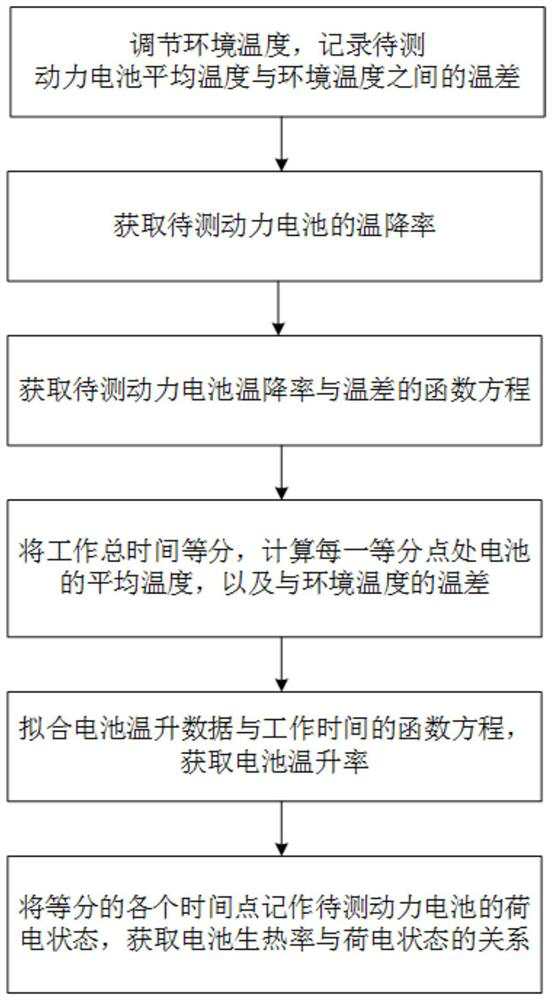

Method used

Image

Examples

Embodiment

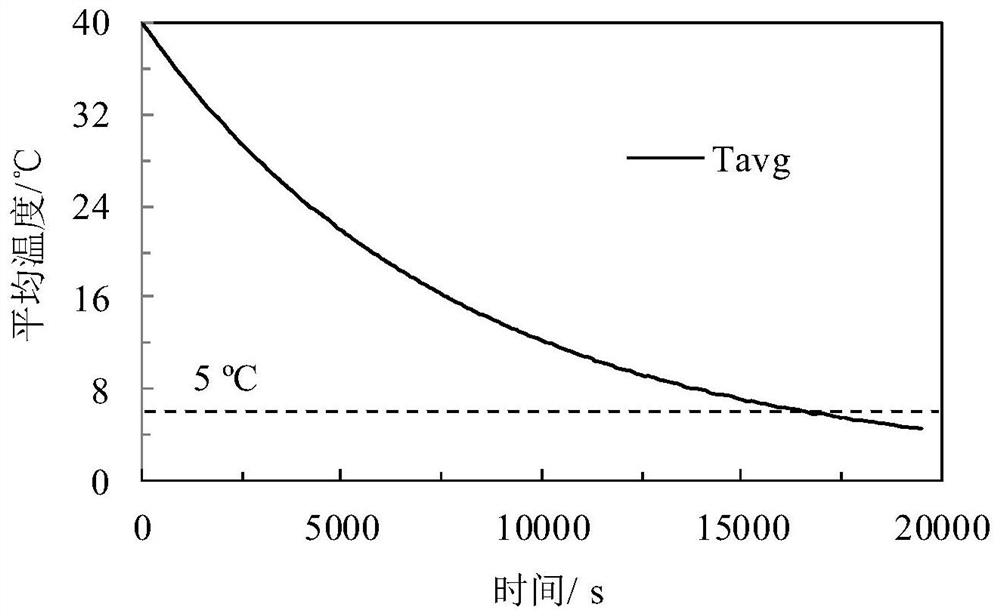

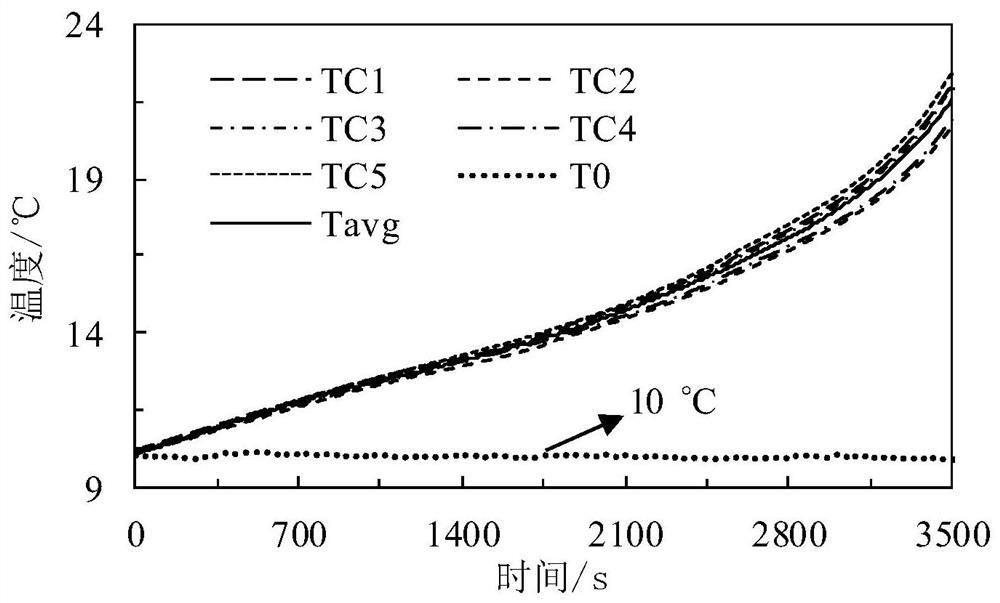

[0042] The invention relates to a method for testing the heat generation rate of a power battery, which is used for testing the heat generation rate of the power battery under different working conditions and working with different rate currents when the initial temperature and working current of the power battery are changed during the working process. heat rate. The power battery in this embodiment is covered by an airgel felt with a thickness of 20 mm, which is placed in the center of a cube-shaped pearl cotton, and the side length of the solid pearl cotton is not less than twice the height of the power battery. The power battery, airgel felt and pearl cotton are all placed in a constant temperature box, and the initial temperature is provided by the constant temperature box, and its temperature control range is greater than the working temperature range of the power battery.

[0043] In this embodiment, the average temperature of the power battery is represented by the ave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com