Rotary type 360-degree product burr detecting device

A detection device and rotary technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of high detection error rate, low detection efficiency, unsuitable for large-scale continuous production, etc., and achieve the effect of stable transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

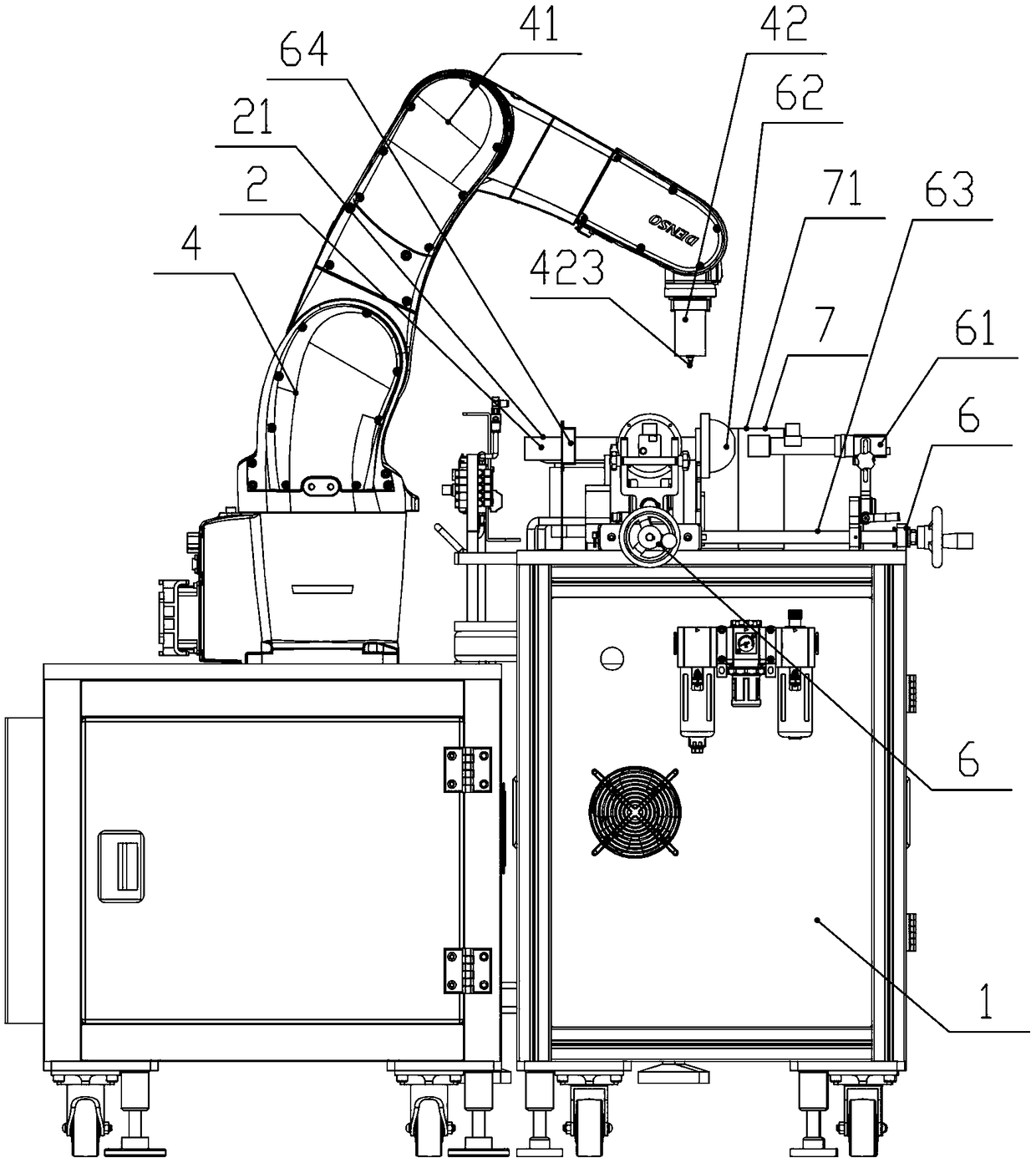

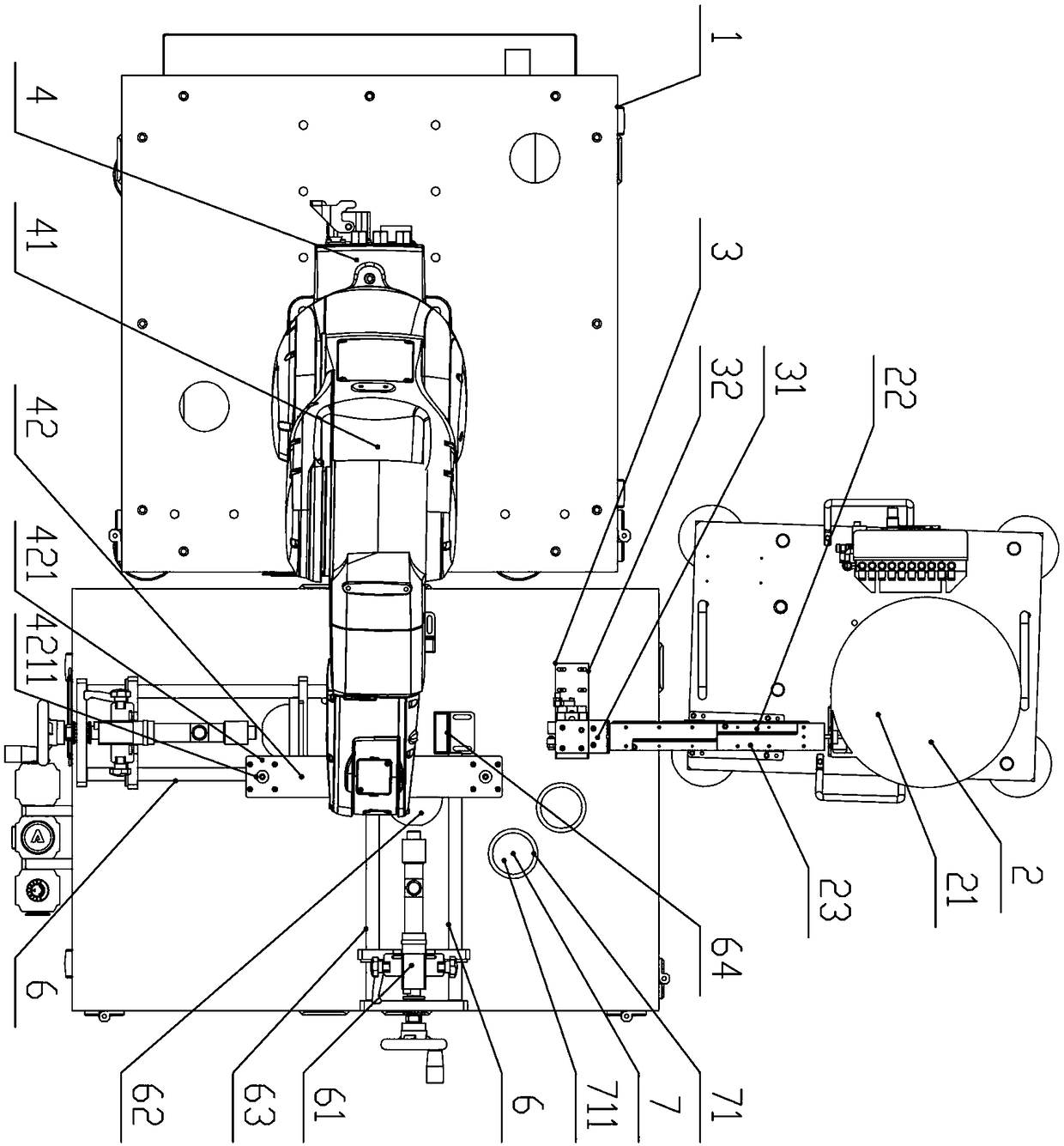

[0043] Figure 1 to Figure 10 A rotating 360-degree product burr detection device according to an embodiment of the present invention is schematically shown. As shown in the figure, the device includes a workbench 1, a material loading part 2, a material distribution part 3, a material transfer part 4, a rotating jig 5, a detection part 6 and a placement part 7,

[0044] Workbench 1 is set on the ground,

[0045] The feeding part 2 includes a vibrating plate 21 and a vibrating guide rail 22 fixed on the right side of the workbench 1, and the discharge port on the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com