Optical measuring system based on integrating sphere

An optical measurement system and integrating sphere technology, applied in the field of optical measurement, can solve the problems of extremely high requirements on the laser incident direction, influence of laser parameter measurement, low system integration, etc., and achieve laser speckle suppression, low manufacturing cost, and system structure. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

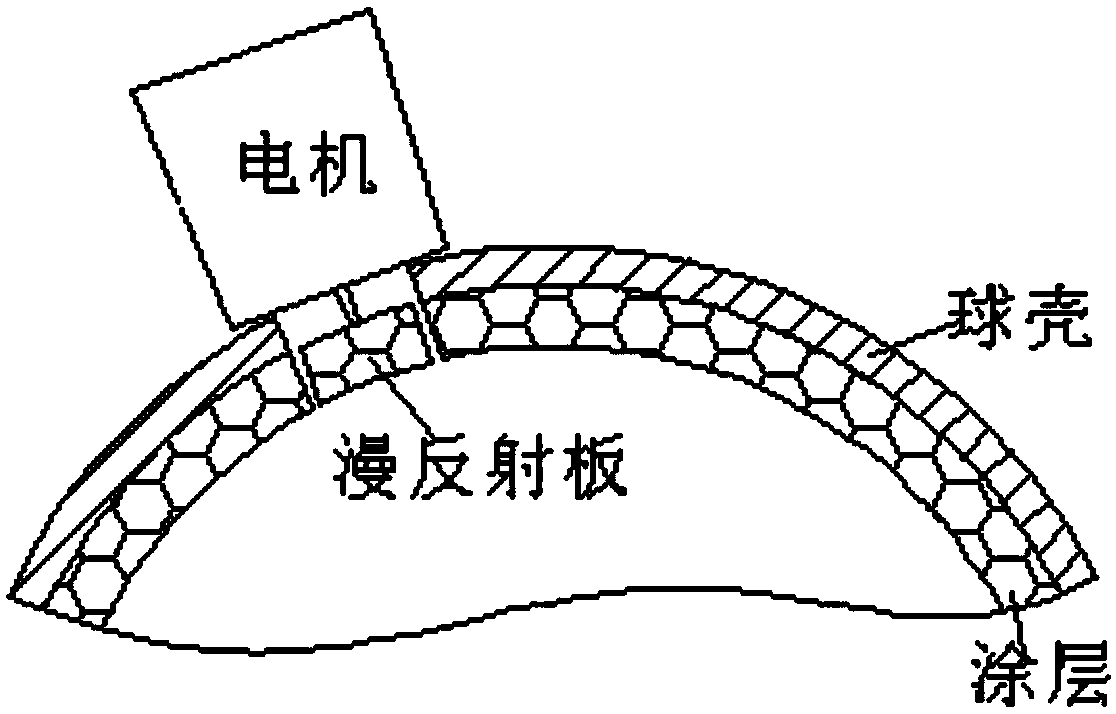

[0023] Such as figure 1 As shown, the optical measurement system based on the integrating sphere includes an incident laser, a beam reducer, an integrating sphere, an energy meter, a photoelectric tube, a fiber coupler, a computer, an oscilloscope and a spectrometer, and the integrating sphere is provided with a light inlet and Three light outlets, the beam reducer is set at the light inlet, the energy meter, photocell and fiber coupler are respectively set at the three light outlets, the output of the energy meter is connected to the computer, and the output of the phototube is connected to the oscilloscope , the output end of the fiber coupler is connected to the spectrometer, the inner wall of the integrating sphere is coated with diffuse reflection coating, and the inner wall of the integrating sphere is provided with a diffuse reflection plate, and a micro DC motor is installed outside the spherical shell of the integrating sphere, and the rotor of the micro DC motor Pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com