Large-span suspended soot blowing platform

A large-span, platform-based technology, which is applied in the fields of combustion product treatment, combustion method, and solid residue removal, can solve the problems of high investment cost, high steel consumption, and large space occupation, and achieve simplified platform support structure and satisfactory layout. Requirements, the effect of increasing the rigidity of the bracket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

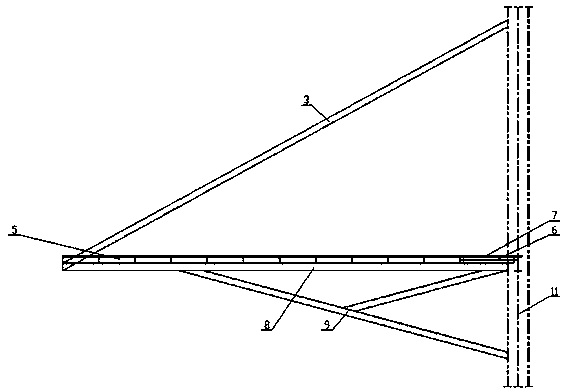

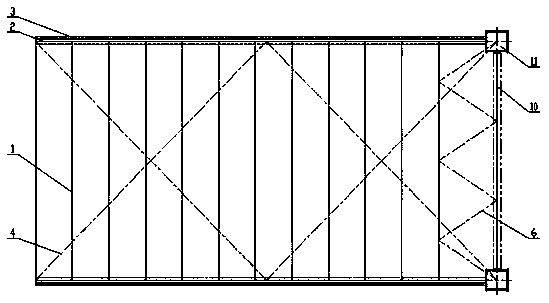

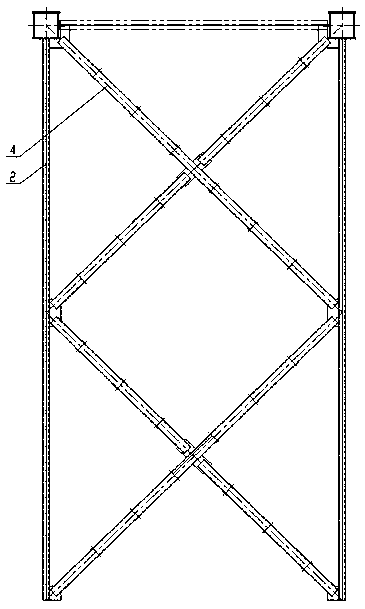

[0020] The present invention will be further explained below in conjunction with the drawings.

[0021] Such as figure 1 with 2 As shown, the large-span suspended sootblowing platform of the present invention includes a platform 1, a bracket 2, a hanger 3, and a truss 4. The bottom of the platform 1 is supported by two brackets 2, a truss 4 is arranged between the brackets 2, and the truss 4 is arranged in a double X shape. One end of the bracket 2 is fixed on the column 11, and the suspended end of the bracket 2 is connected to the column 11 through the hanger 3 to form an upper hanging and lower supporting structure. The platform 1 is composed of a platform frame 5, a horizontal support 6, and a grid 7. A horizontal support 6 is arranged on the side of the platform 1 close to the beam 10 and the column 11, and several platform frames 5 are arranged side by side on the outside. A grid 7 is laid above the support 6. The bracket 2 is composed of horizontal rods 8 and diagonal br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com