Physical deoxidizing method and device for air cooling unit condensation water

An air-cooling unit and condensate technology, which is applied in separation methods, chemical instruments and methods, feed water heaters, etc., can solve problems affecting the health of operators, toxicity, etc., and achieve the effect of ensuring safe and stable operation and solving uncertain effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

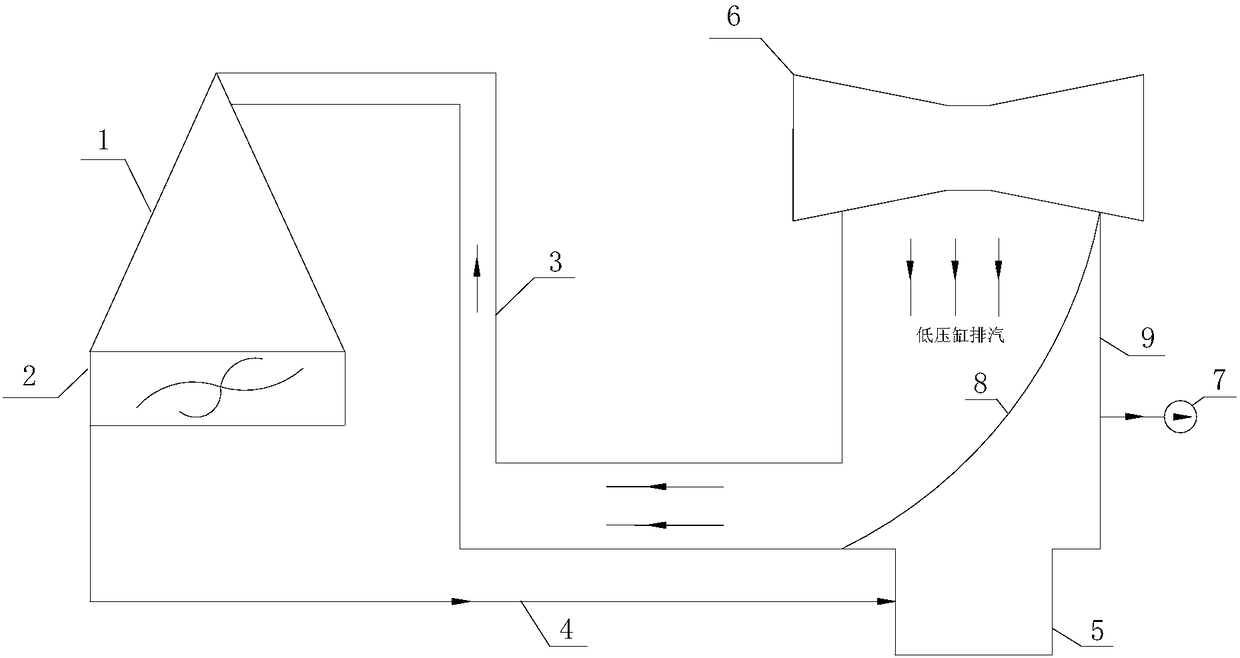

[0034] This embodiment provides a method for physically removing oxygen from condensed water of an air-cooling unit, such as figure 2 As shown, the physical oxygen removal method includes the following steps S101 to S103.

[0035] S101. Make part of the exhaust steam output from the low-pressure cylinder of the steam turbine enter the hot well of the exhaust device.

[0036] In this step, part of the exhaust steam entering the hot well of the exhaust device accounts for 1 / 10-1 / 7 of the total exhaust steam output from the low-pressure cylinder of the steam turbine.

[0037] The step S101 specifically is to make part of the exhaust steam output from the low-pressure cylinder of the steam turbine enter the hot well of the exhaust device through the deoxygenated steam pipe connected to the bottom of the horizontal pipe section of the exhaust pipe of the exhaust device. For example, from the lower part of the well into the well.

[0038] The diameter of the deoxygenation steam p...

Embodiment 2

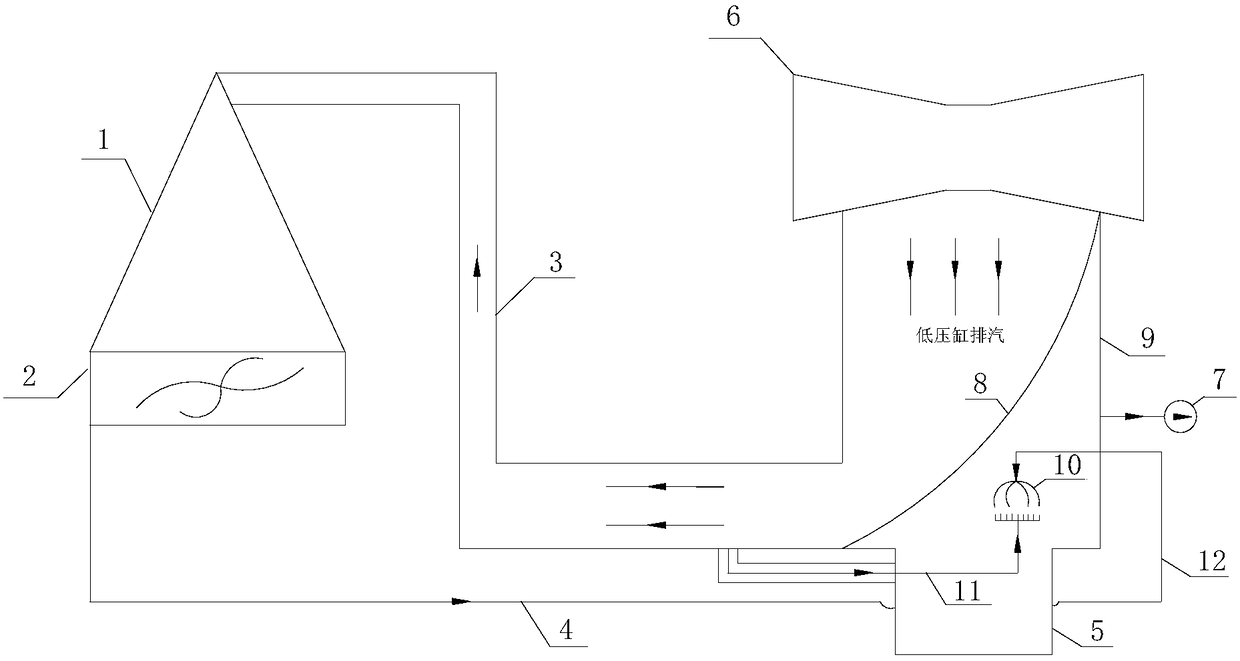

[0047] This embodiment provides a physical deaeration device for condensed water of an air-cooled unit, taking a 350MW unit as an example, as image 3 As shown, the physical oxygen removal device includes:

[0048] The deoxygenated steam pipeline 11 is used to make part of the exhaust steam output by the low-pressure cylinder 6 of the steam turbine enter the hot well 5 of the exhaust device 9;

[0049] The return water pipeline 12 is used to make the condensed water cooled by the air-cooled island 1 output by the condensed water pipeline 4 enter the top of the hot well 5 of the exhaust device 9;

[0050] The atomizing nozzle assembly 10 is used to atomize the condensed water output from the return water pipe 12. After the atomization, it will convect with the bottom-up exhaust steam in the hot well from top to bottom, so as to remove part of the dissolved oxygen in the condensed water.

[0051] In the present embodiment, the head end of the deoxygenation steam pipeline 11 is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com