Handheld mine downhole safety inspection equipment

An underground, hand-held technology, applied in mining equipment, mining equipment, earth-moving drilling, etc., can solve the problems of low safety value, high accident rate, threat to employee life safety, etc., achieve good airtight performance, strengthen management standards , the effect of eliminating management loopholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

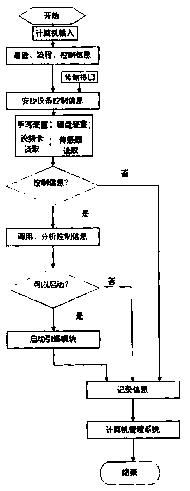

Method used

Image

Examples

Embodiment 1

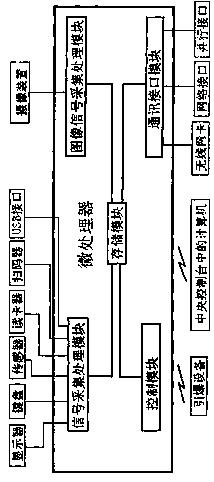

[0027] The concrete technical scheme that the present invention solves its technical problem adopts is:

[0028] 1. Hand-held mine safety management inspection equipment, the operating system software adopts a configurable embedded real-time operating system eCos (English full name: Embedded Configurable Operating System), and various hardware on the hand-held mine safety management inspection equipment Components: Sunplus spce3200 main control chip (32-bit microprocessor produced by Sunplus Technology Co., Ltd.), 16M Ram (capacity) memory, 256M Nand Flash (non-volatile flash memory) data storage chip.

[0029] 2. The hand-held mine safety management inspection equipment adopts the embedded graphical user interface of Microwindows (a small graphical user interface with multi-layer windows), touch screen, input keyboard, handwriting recognition input and other input components.

[0030] 3. Hand-held mine safety management inspection equipment, the database adopts the Fat16 file...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com