A strain for fermented feed

A fermented feed and bacterial strain technology, applied in animal feed, animal feed, microbial-based methods, etc., can solve problems such as unstable effects, lack of perfect management mechanism, quality standard evaluation system, market chaos, etc., to improve survival rate and output , enhance immunity and resistance to environmental stress, and protect health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1: the screening of bacterial strain

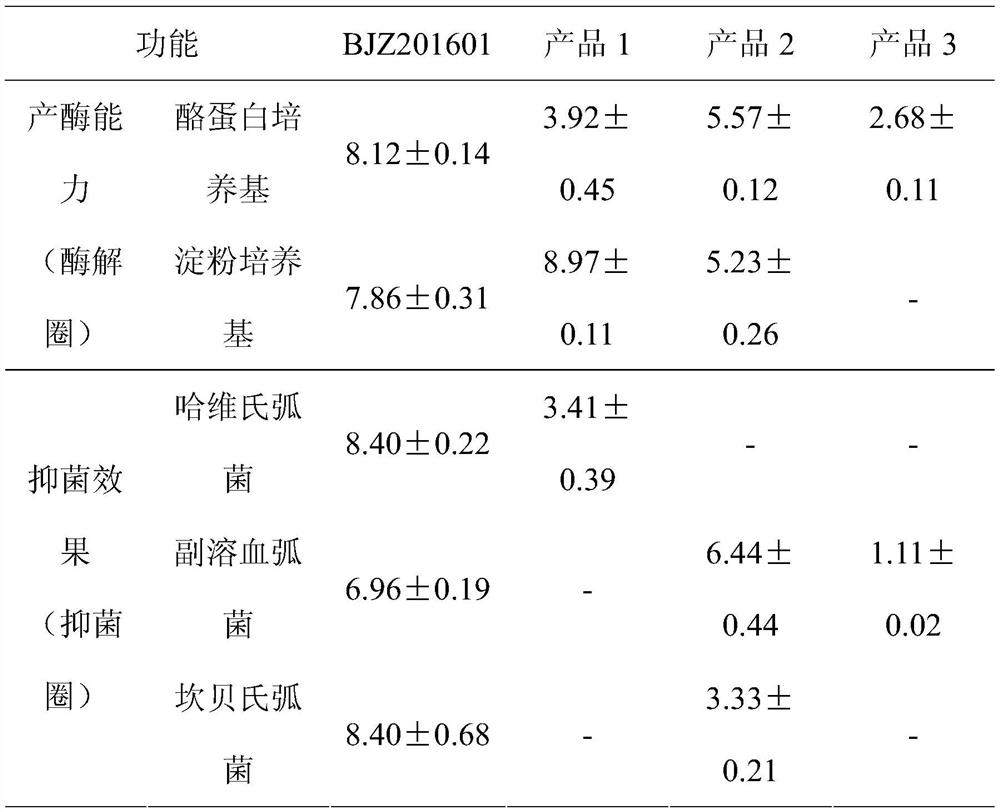

[0012] Thirty-three purified strains were screened from the intestines of surviving individual ponds with diseased shrimp in the late stage of shrimp culture by the streak purification method. Firstly, the ability of the purified strains to produce protease and amylase was evaluated by using casein solid medium and starch solid medium. Protease and amylase-producing strains, on the basis of the screened strains, three common aquatic pathogens (Vibrio harveyi (V.harveyi), Vibrio campbellii (V. campbellii), Vibrio parahaemolyticus (V. parahaemolyticus) is an indicator bacterium, and checks the antagonism effect of the screened high-efficiency protease and amylase strains on pathogenic bacteria. After comprehensive evaluation, a fully functional bacterial strain is screened from the isolated 33 strains of purified bacteria, which has strong enzyme production ability , and have a certain antagonistic effect on pathogenic bac...

Embodiment 2

[0018] Embodiment 2: Preparation of fermented feed and evaluation of breeding effect

[0019] The screened bacillus BJZ201601 strain and another strain of bacillus MZ1 strain (screened in other experiments) were used to prepare prawn fermented feed. Brown sugar and inorganic salts are mixed according to the mass fraction of 37, 18, 18, 15, 8, 3.5, and 0.5, and then matured first, and then enzymatically hydrolyzed for 36 hours, then added with Bacillus and yeast, and carried out at 34°C Aerated and fermented for 12 hours; then added with Lactobacillus, anaerobic fermented for 96 hours at 36°C.

[0020] Said curing is to put the raw materials into the steam tank, input steam into the steam tank, and stir the raw materials at the same time, after the raw materials are matured, release the steam and dry them.

[0021] In the enzymolysis, the enzyme used is protease, which is produced from Aspergillus niger; the temperature of the enzymolysis is 37 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com