Process method for preparing fuel gas from coal

A process method and gas technology, which can be used in the manufacture of combustible gas, granular/powder fuel gasification, petroleum industry, etc., can solve the problems of poor coal adaptability, inflexible operation, and poor economy, and achieve low steam consumption and operation. Simple, flexible and environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

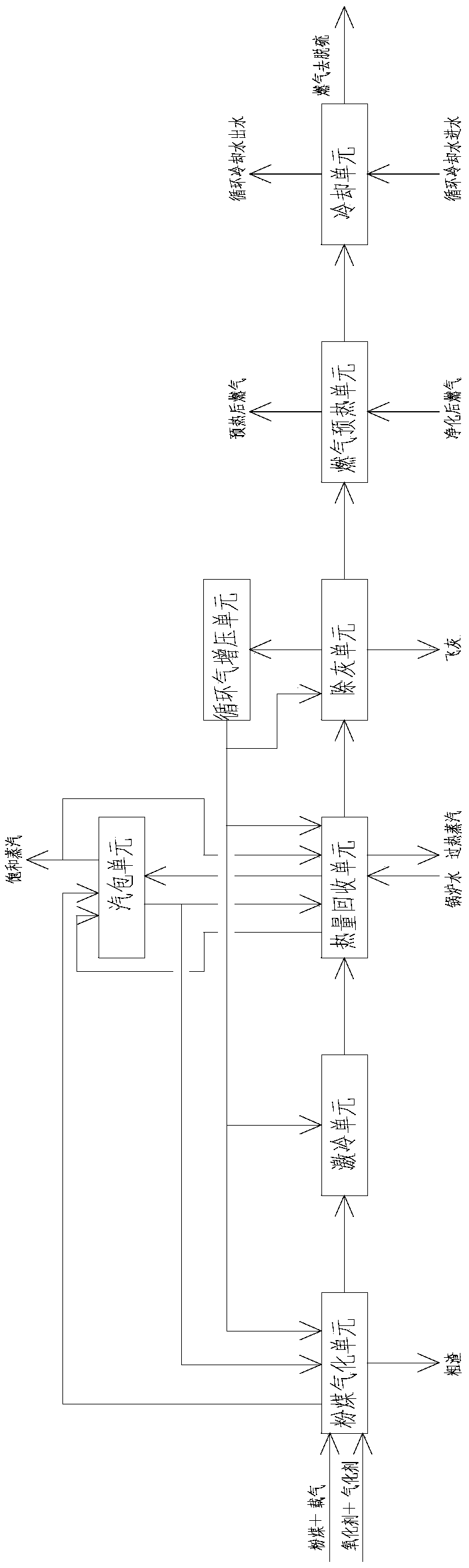

[0032] Such as figure 1 As shown, in this embodiment, the coal-to-gas system includes a pulverized coal gasification unit, a chilling unit, a heat recovery unit, an ash removal unit, a circulating gas pressurization unit, a steam drum unit, a gas preheating unit and a cooling unit.

[0033] Pulverized coal from the pulverized coal conveying device, oxidant and gasification agent from public works enter the pulverized coal gasification unit to produce gas; the gas outlet temperature of the pulverized coal gasification unit is 900-1200 °C, and the temperature of the slag outlet is 100 °C higher than the melting point of coal ash; About 40-75% of the ash is discharged from the slag outlet in a molten state, and about 25-60% of the ash enters the chilling unit in the form of fly ash along with the gas; the pulverized coal gasification pressure is normal pressure to 0.5MPa. The gasification unit adopts an entrained bed gasifier and a water wall refractory lining.

[0034] The quen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com