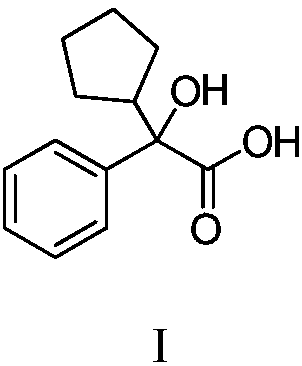

Method for purifying glycopyrronium bromide intermediate 2-cyclopentyl-2-hydroxyphenylacetic acid

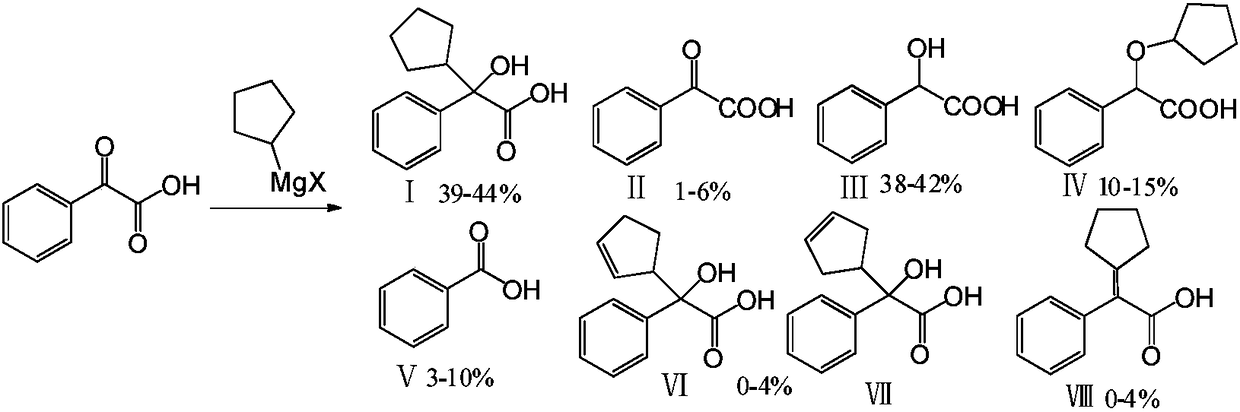

A kind of technology of hydroxyphenylacetic acid and purification method, applied in the field of recrystallization and purification of glycopyrronium bromide intermediate 2-cyclopentyl-2-hydroxyphenylacetic acid I, can solve problems such as low crude product purity and many by-products, and achieve Improve product purity, improve the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Purification of 2-cyclopentyl-2-hydroxyphenylacetic acid

[0042] Prepare the cyclopentyl Grignard reagent first, then add 495g of acetophenone acid and 2.5LTHF into a 20L four-necked bottle, add 2.1eq of the cyclopentyl Grignard reagent dropwise at 15°C to 25°C, and use it after the reaction is completed. Quenched with 4N hydrochloric acid, then extracted with MTBE, washed with alkali and brine, and concentrated to obtain 563 g of the intermediate 2-cyclopentyl-2-hydroxyphenylacetic acid oil.

[0043] Add 150g of ethanol and 300g of purified water to the oil obtained from the above reaction, heat up to 55-65°C to dissolve, then slowly cool down to 0-5°C, keep warm for 1 hour, and filter with suction to obtain a brown-yellow solid; Then use 227g of ethanol and 300g of purified water, heat up to 70-80°C to dissolve, then slowly cool down to 0-5°C, keep warm for 1 hour, and then filter with suction to obtain a light yellow solid; use 300g of ethanol and 160g of purified w...

Embodiment 2

[0045] Prepare 578g of 2-cyclopentyl-2-hydroxyphenylacetic acid oil by the method in Example 1, add 160g of ethanol, 640g of purified water, heat up to 70-80°C to dissolve, then slowly cool down to 0-5°C , after heat preservation for 1 hour, suction filtration to obtain brown-yellow solid; add 327g of ethanol and 300g of purified water to the wet product, heat up to 75-80°C to dissolve, then slowly cool down to 0-5°C, hold heat for 1 hour, and then suction-filter, Obtain 204g of a light yellow solid; warm the crude product to 60-80°C with 2000ml of toluene and dissolve it, then slowly cool it down to -5-0°C, keep stirring for 1 hour, and then filter with suction to obtain a off-white solid. After dissolving at 80-110°C, slowly lower the temperature to 0-5°C, keep warm for 1 hour, filter with suction, and dry to obtain 156.8g of off-white solid with a yield of 21.6% and an HPLC purity of 98.2%.

Embodiment 3

[0047]Prepare 552g of 2-cyclopentyl-2-hydroxyphenylacetic acid oil by the method of Example 1, add 200g of ethanol and 350g of purified water, heat up to 50-70°C to dissolve, then slowly cool down to -5-0 ℃, keep warm for 1 hour, and filter with suction to obtain brown-yellow solid; add 227g of ethanol and 300g of purified water to the wet product, heat up to 75-85℃ to dissolve, then slowly cool down to 0-5℃, keep warm for 1 hour, and then suction-filter , to obtain 201g of a light yellow solid; warm the crude product to 60-80°C with 1300ml of toluene to dissolve it, then slowly cool it down to 0-5°C, keep stirring for 1 hour and then filter it with suction to obtain a off-white solid. After dissolving at 80-110°C, slowly lower the temperature to 0-5°C, keep warm for 1 hour, filter with suction, and dry to obtain 161.9 g of off-white solid with a yield of 22.3% and an HPLC purity of 98.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com