Treatment method of garbage leachate

A landfill leachate and treatment method technology, which is applied in the field of landfill leachate treatment, can solve the problems of difficulty in landfill leachate treatment, reduction of various pollutants in leachate, refractory membrane retentate, etc., to achieve stable water output, The effect of low operating costs and low external environmental requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A treatment method for landfill leachate, comprising the following steps:

[0046] 1) Quasi-aerobic mineralized garbage bed treatment:

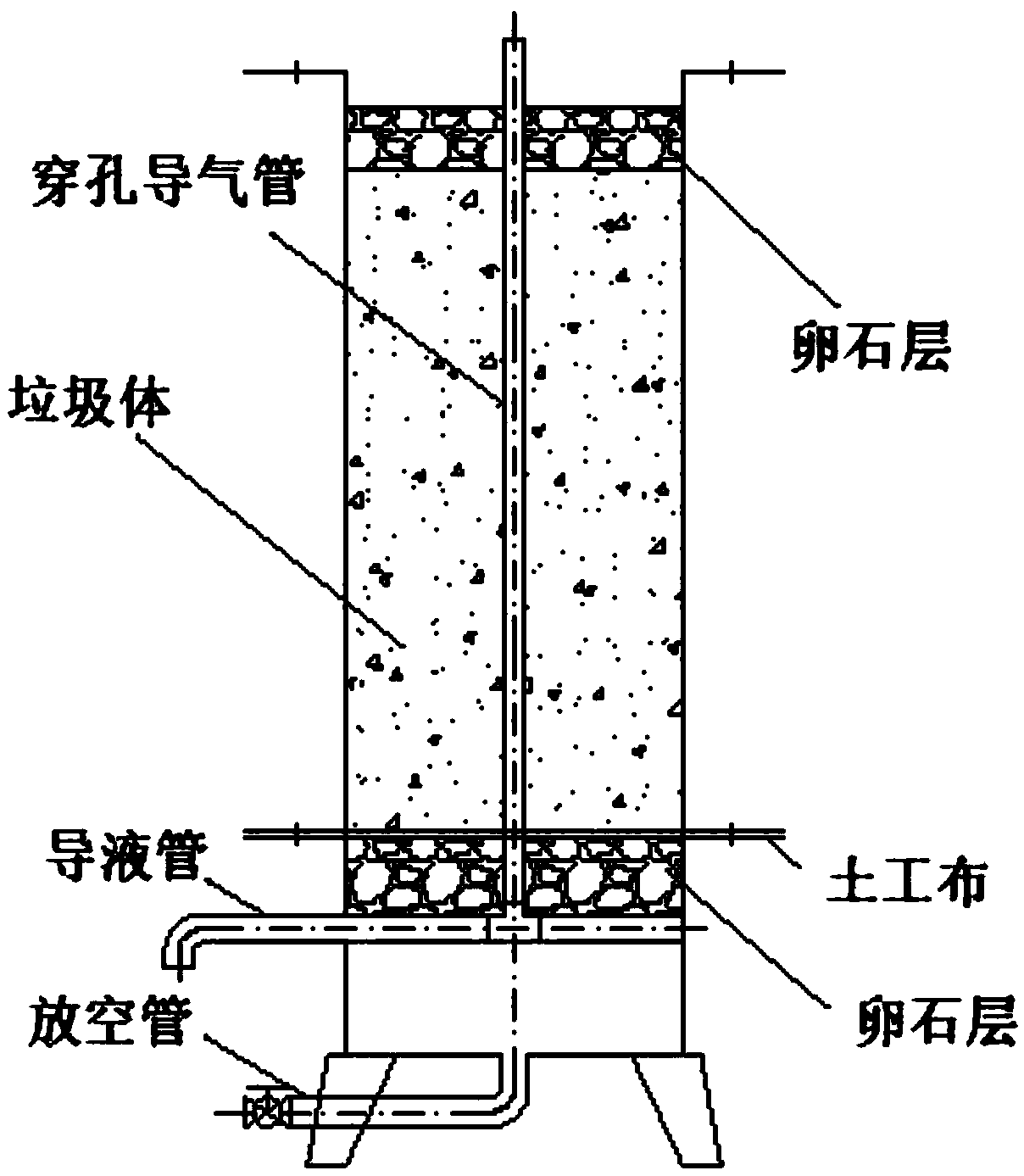

[0047] A1) filling of the quasi-aerobic mineralized garbage bed: the quasi-aerobic mineralized garbage bed is as follows figure 1 As shown, it includes: a reaction bed body, a mineralized garbage column is arranged in the reaction bed body, and the bottom of the reaction bed body is connected with a vent pipe; the mineralized garbage column is filled with garbage bodies. A pebble layer, a garbage body, a geotextile, a pebble layer, and a support plate are arranged respectively from top to bottom, and a perforated air guide tube is vertically penetrated through the center of the mineralized garbage column; the bottom end of the perforated air guide tube communicates with a horizontally arranged liquid guide tube; The loading capacity of the garbage body is 38-40kg, and the compacted density is 1030-1130kg / m 3 ; The garbage body is the...

Embodiment 2

[0058] A treatment method for landfill leachate, comprising the following steps:

[0059] 1) Quasi-aerobic mineralized garbage bed treatment:

[0060] A1) filling of the quasi-aerobic mineralized garbage bed: the quasi-aerobic mineralized garbage bed is as follows figure 1 As shown, it includes: a reaction bed body, a mineralized garbage column is arranged in the reaction bed body, and the bottom of the reaction bed body is connected with a vent pipe; the mineralized garbage column is filled with garbage bodies. A pebble layer, a garbage body, a geotextile, a pebble layer, and a support plate are arranged respectively from top to bottom, and a perforated air guide tube is vertically penetrated through the center of the mineralized garbage column; the bottom end of the perforated air guide tube communicates with a horizontally arranged liquid guide tube; The loading capacity of the garbage body is 38-40kg, and the compacted density is 1030-1130kg / m 3 ; The garbage body is the...

Embodiment 3

[0071] A treatment method for landfill leachate, comprising the following steps:

[0072] 1) Quasi-aerobic mineralized garbage bed treatment:

[0073] A1) filling of the quasi-aerobic mineralized garbage bed: the quasi-aerobic mineralized garbage bed is as follows figure 1 As shown, it includes: a reaction bed body, a mineralized garbage column is arranged in the reaction bed body, and the bottom of the reaction bed body is connected with a vent pipe; the mineralized garbage column is filled with garbage bodies. A pebble layer, a garbage body, a geotextile, a pebble layer, and a support plate are arranged respectively from top to bottom, and a perforated air guide tube is vertically penetrated through the center of the mineralized garbage column; the bottom end of the perforated air guide tube communicates with a horizontally arranged liquid guide tube; The loading capacity of the garbage body is 38-40kg, and the compacted density is 1030-1130kg / m 3 ; The garbage body is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com