Rattan waterproof and sweat resisting dyeing method

A dyeing method, the technology of rattan and grass, applied in the field of rattan and grass dyeing, can solve the problems of rattan and grass handicrafts such as reduced performance and quality, adverse effects on the environment and human body, unstable fiber strength, etc., to achieve improved ultraviolet protection performance and enhanced waterproofing Anti-perspiration ability, effect of reducing transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

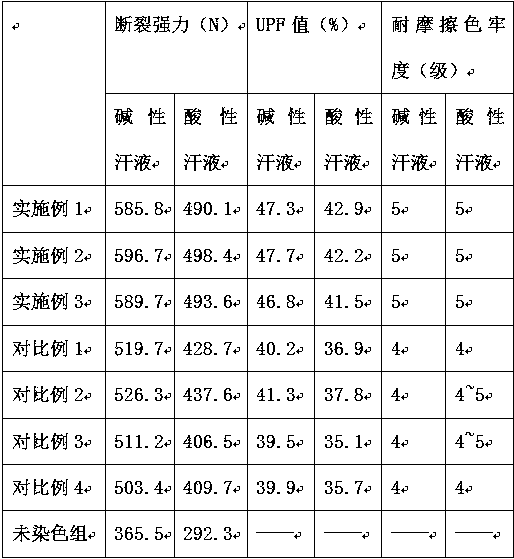

Examples

Embodiment 1

[0017] In an embodiment of the present invention, a waterproof and sweat-resistant dyeing method of wisteria, the specific method is as follows:

[0018] (1) Submerge the rattan grass in an aqueous solution of potassium alginate with a mass fraction of 5.4% and a temperature of 52°C for 28 minutes, then drain the liquid until no water drips, and place it in a refrigerator at a temperature of 1°C Refrigerate at constant temperature for 24 minutes, take it out, and get the pretreated rattan grass;

[0019] (2) Submerge the pretreated rattan grass in the dyeing agent for 50 minutes and stir continuously, remove the agent, magnetize it for 51 minutes, and dry it under hot pressing at a temperature of 45°C;

[0020] The preparation method of described staining agent specifically comprises the following steps:

[0021] A. Weigh raw materials by weight, 2.1 parts of nano-chitosan, 0.32 parts of Burnet polysaccharide, 0.41 part of Luo Han Guo polysaccharide, 53 parts of fresh hawthor...

Embodiment 2

[0027] In an embodiment of the present invention, a waterproof and sweat-resistant dyeing method of wisteria, the specific method is as follows:

[0028] (1) Submerge the rattan grass in an aqueous solution of potassium alginate with a mass fraction of 5.6% and a temperature of 54°C for 30 minutes, then drain and drain until no water drips, and place it in a refrigerator at a temperature of 1.5°C Refrigerate at constant temperature for 26 minutes, take it out, and get the pretreated vine grass;

[0029] (2) Submerge the pretreated rattan grass in the dyeing agent for 55 minutes and stir continuously, remove the agent, magnetize it for 54 minutes, and dry it under hot pressing at a temperature of 46°C;

[0030] The preparation method of described staining agent specifically comprises the following steps:

[0031] A. Weigh raw materials by weight, 2.2 parts of nano-chitosan, 0.34 parts of Burnet polysaccharide, 0.43 parts of Luo Han Guo polysaccharide, 54 parts of fresh hawthor...

Embodiment 3

[0037] In an embodiment of the present invention, a waterproof and sweat-resistant dyeing method of wisteria, the specific method is as follows:

[0038] (1) Submerge rattan grass in an aqueous potassium alginate solution with a mass fraction of 5.8% and a temperature of 56°C for 32 minutes, then drain and drain until no water drips, and place it in a refrigerator at a temperature of 2°C Refrigerate at constant temperature for 28 minutes, take it out, and get the pretreated vine grass;

[0039] (2) Submerge the pretreated rattan grass in the dyeing agent for 60 minutes and stir continuously, remove the agent, magnetize it for 57 minutes, and dry it under hot pressure at 47°C;

[0040] The preparation method of described staining agent specifically comprises the following steps:

[0041] A. Weigh raw materials by weight, 2.3 parts of nano-chitosan, 0.36 parts of Burnet polysaccharide, 0.45 parts of Luo Han Guo polysaccharide, 55 parts of fresh hawthorn leaves, 30 parts of fres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com