Device for grinding inner wall and outer wall of tire

A technology for inner and outer walls and tires, applied in grinding/polishing safety devices, grinding machines, grinding/polishing equipment, etc., can solve the problems of low efficiency, time-consuming and labor-intensive manual grinding, and achieve high efficiency, time-consuming and labor-intensive solutions, and practicality strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

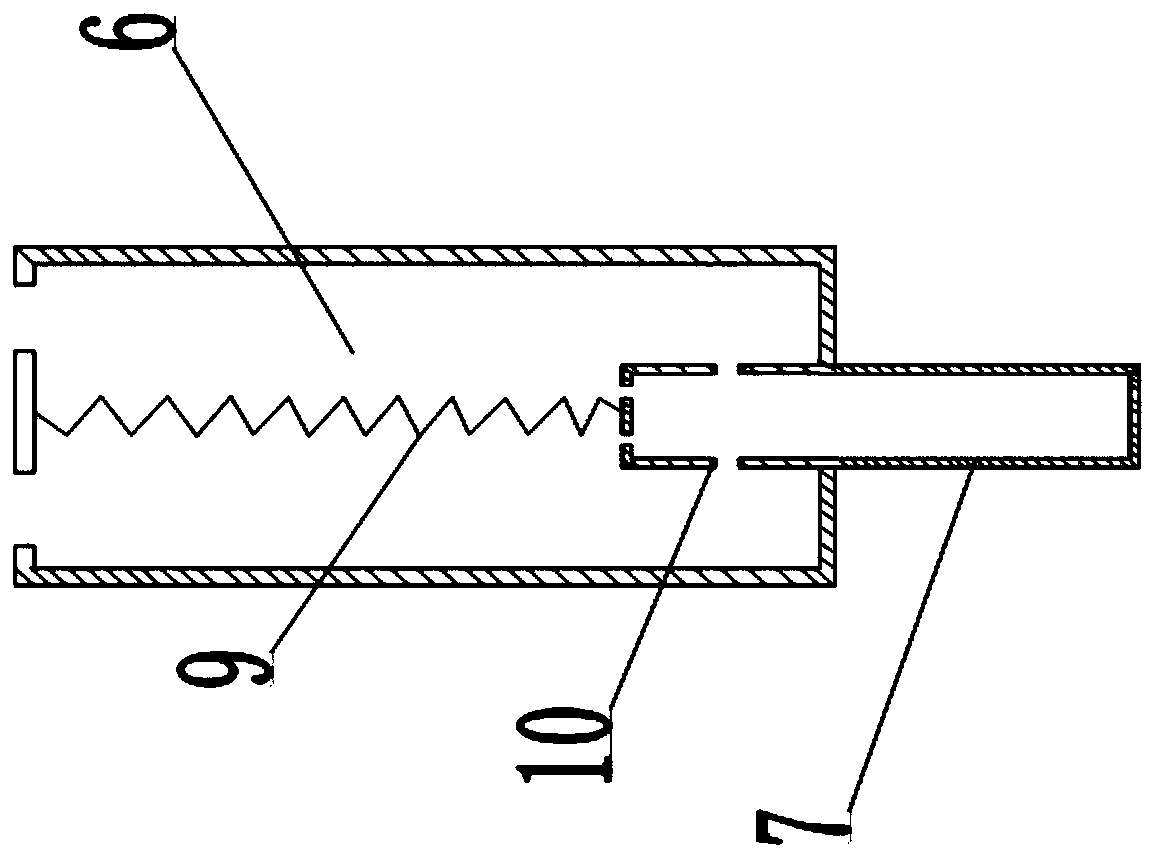

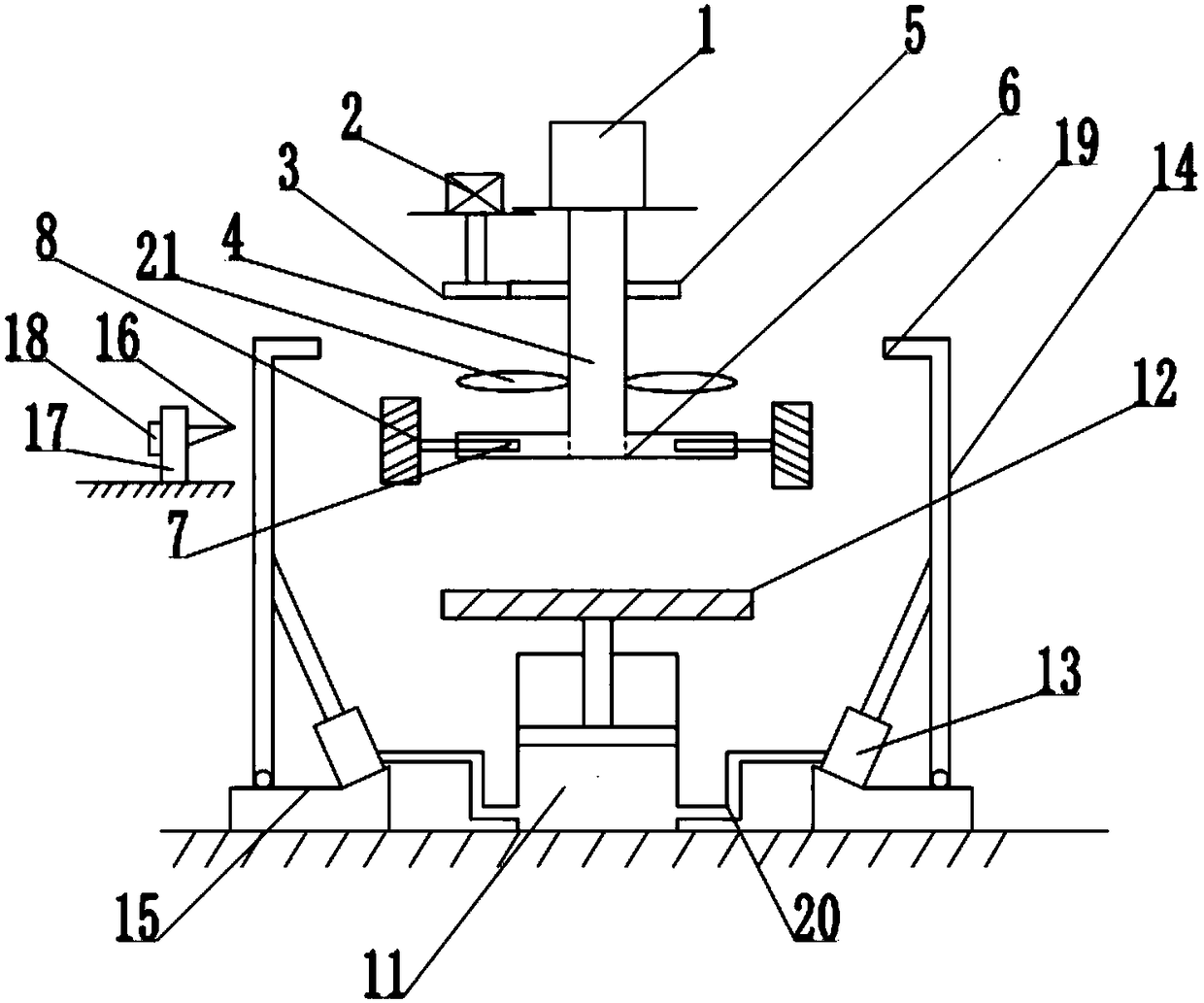

[0019] The specific embodiment of the present invention is as follows: first, the tire is placed on the circular tray 12, the first cylinder 11 lifts the circular tray 12 upwards to the place where the polishing sheet 8 is flush with the inner surface of the tire, the air pump 1 is turned on, and the air flow passes through The hollow main rod 4 finally flows into the telescopic rod 7. When the air pressure reaches a certain value, the telescopic rod 7 moves away from the branch pipe 6 under the push of the airflow, until the grinding sheet 8 contacts and squeezes the inner wall of the tire, supporting the tire rise. Simultaneously, telescopic rod 7 is in motion process, and the spring 9 that connects telescopic rod 7 is stretched, stretches out outside branch pipe 6 until the air hole 10 on the telescopic rod 7, and the air-flow in branch pipe 6 overflows through air hole 10, with this Control the air pressure inside the hollow main rod 4 and the branch pipe 6 to make the gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com