Processing equipment for luggage compartment internal decorative plate with sensor

A technology for interior decorative panels and processing equipment, applied to metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of low processing efficiency, achieve the effects of improving processing efficiency, saving costs, and improving product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

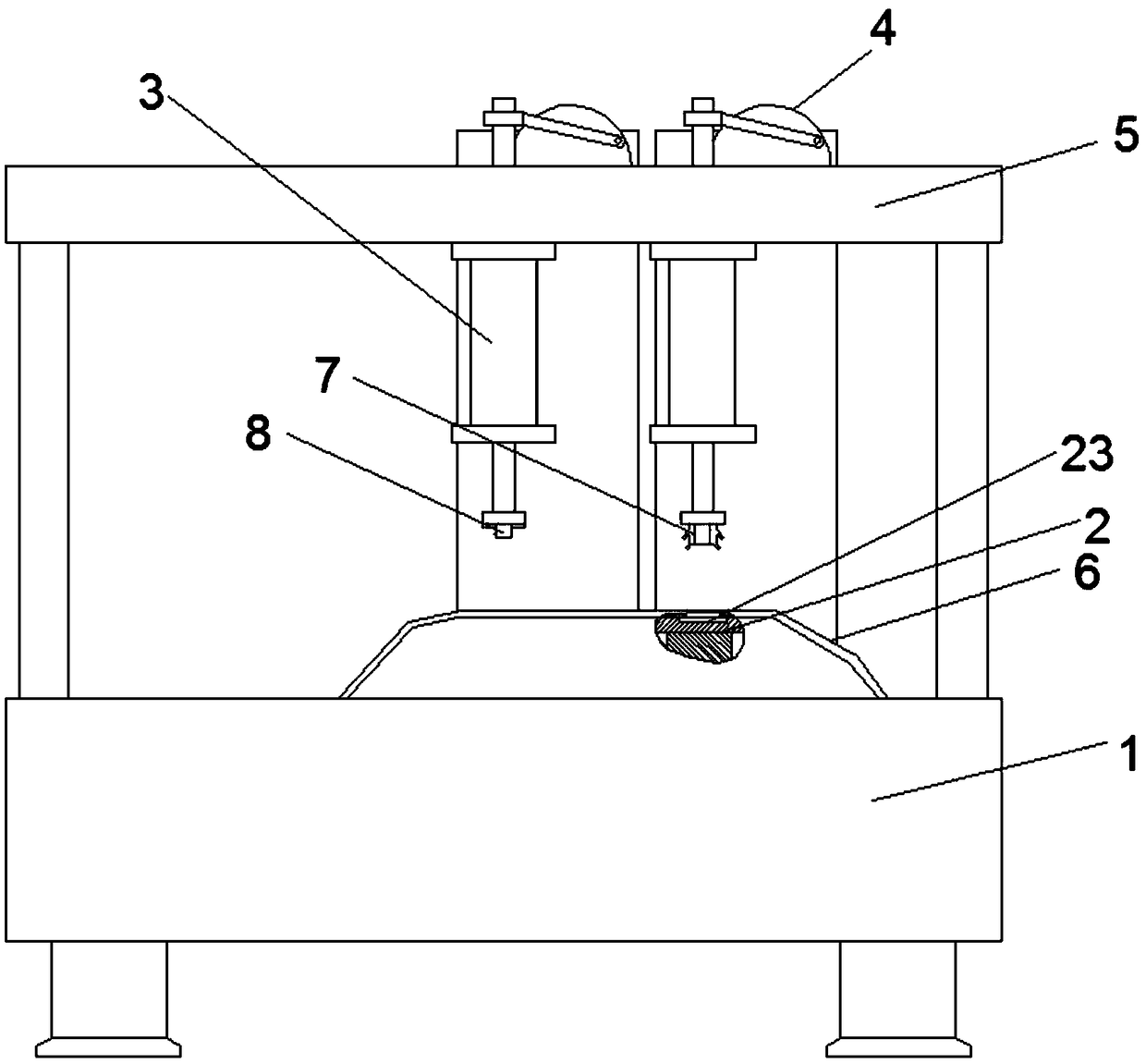

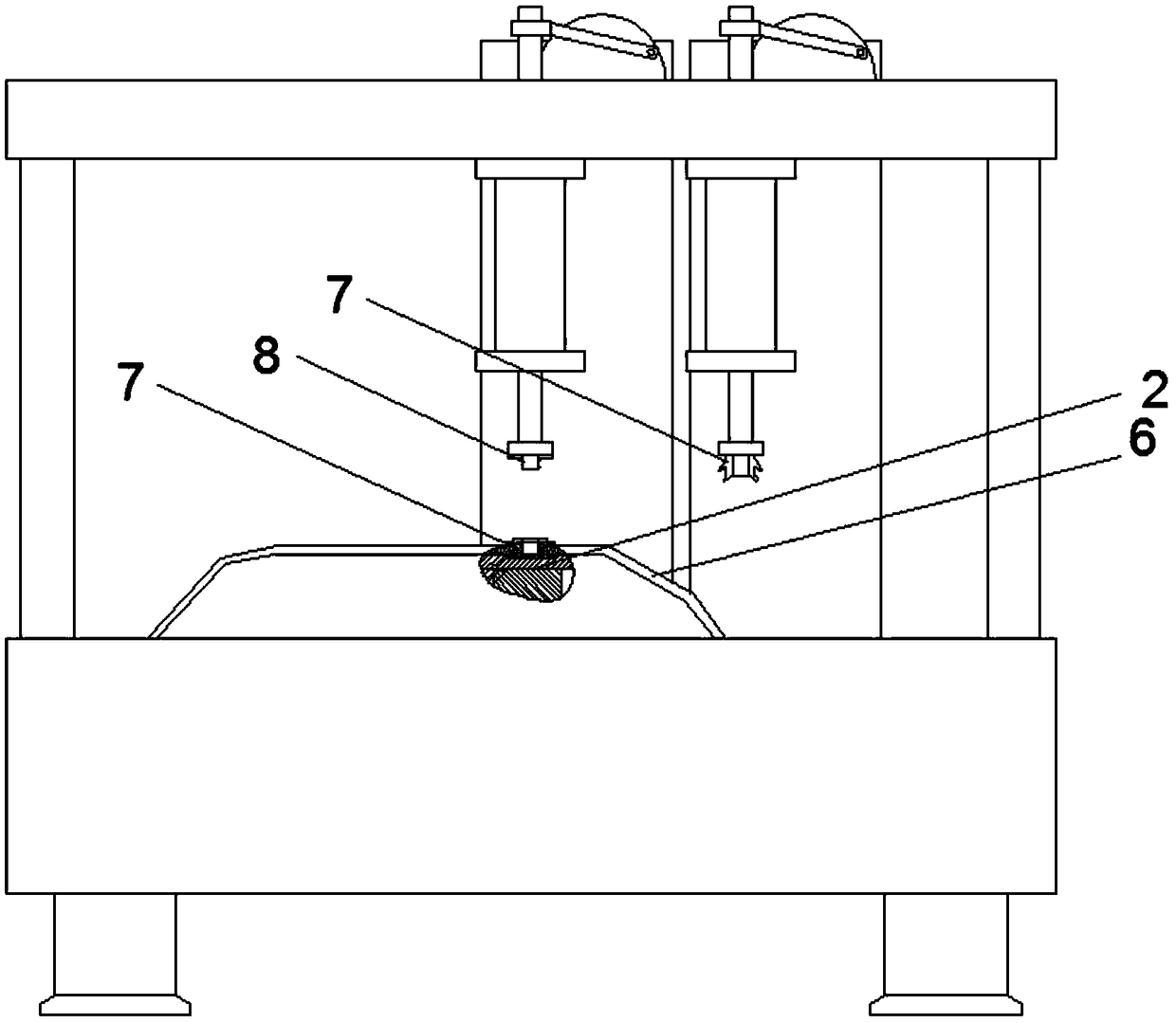

[0020] The processing equipment for the luggage compartment interior trim panel equipped with sensors includes a machine table 1, a mounting bracket, a stamping mechanism 3 and a sliding mechanism 2. The mounting bracket is fixed on the machine platform 1 and includes pillars arranged at four corners and a top mounting plate 5 horizontally installed on the top of the pillars. The machine platform 1 is provided with a chute 11 extending longitudinally to guide the sliding table 21 to move.

[0021] The stamping mechanism 3 has two groups with the same structure, which are respectively used for installing the mounting part 7 and the inductor 8 . Two groups of stamping mechanisms 3 are arranged front and rear in the mounting bracket, the stamping mechanism 3 with the installation part 7 is called the first stamping mechanism at the front, and the stamping mechanism 3 with the inductor 8 is called the second stamping mechanism at the rear, which can be Corresponding to the feedin...

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is that the driving mechanism is a motor, the output shaft of the motor is arranged horizontally and horizontally, and a sliding driving wheel 25 is installed on the output shaft, and the sliding driving wheel 25 is hinged There is a sliding connecting rod, and the sliding connecting rod is hingedly connected with the sliding platform 21 . When returning the slide table 21, it is driven by a motor.

Embodiment 3

[0035] The difference between this embodiment and Embodiment 1 is that the driving mechanism is a motor, which is used to drive the slide table 21 when returning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com