Glass cleaning equipment for building

A cleaning equipment and construction technology, applied in the field of construction glass cleaning equipment, can solve the problems of low work efficiency, high labor intensity, waste of labor, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

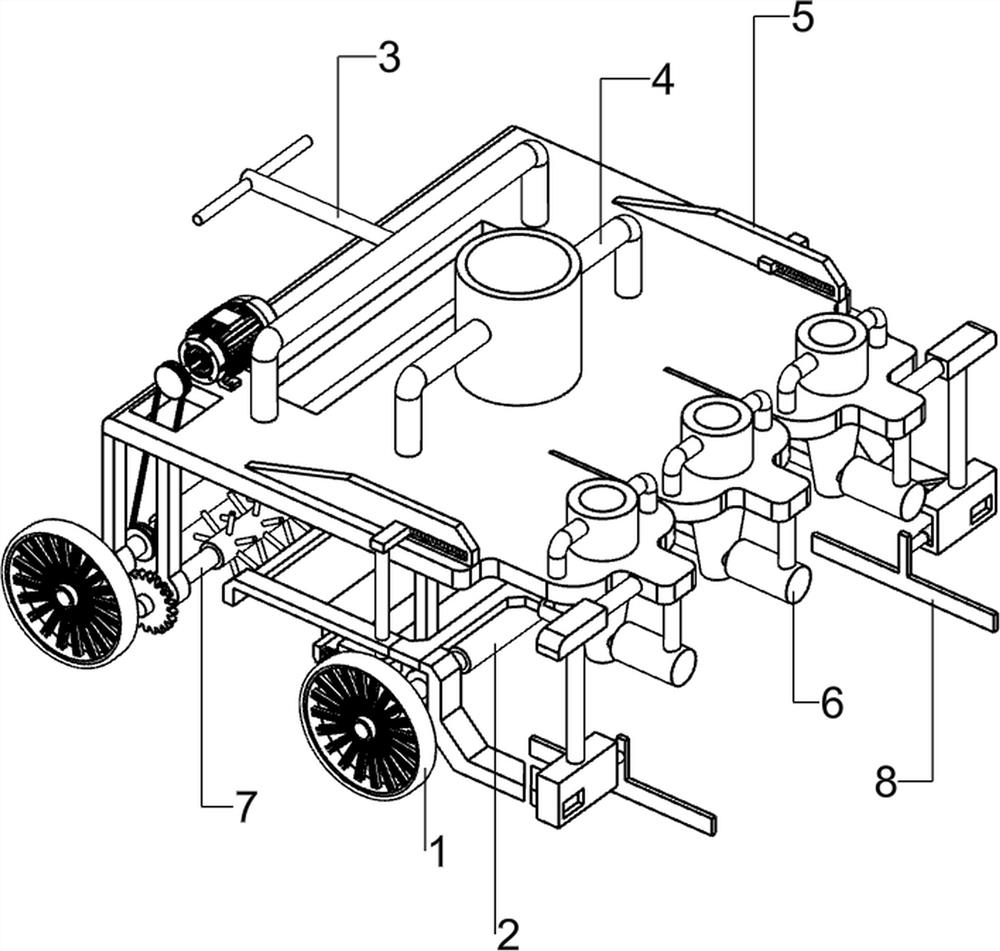

[0063] A kind of building glass cleaning equipment, such as figure 1 As shown, it includes a rotating wheel 1, a first rotating shaft 2, a power mechanism 3 and a flushing mechanism 4, and the left and right sides of the lower part of the power mechanism 3 are connected with the first rotating shaft 2 in a rotational manner, and the first rotating shaft 2 is provided on the front and rear sides. There is a rotating wheel 1, and a flushing mechanism 4 is provided on the power mechanism 3.

[0064] When people need to clean the glass, the glass is first placed on the right side of the device, then water is poured into the flushing mechanism 4, and then the power mechanism 3 is started, and the power mechanism 3 drives the first rotating shaft 2 and the rotating wheel 1 to rotate continuously, driving the machine. The equipment moves to the right, so that the washing mechanism 4 cleans the glass, and after completion, the power mechanism 3 can be closed.

Embodiment 2

[0066] On the basis of Example 1, such as Figure 2-3 As shown, the power mechanism 3 includes a bearing seat 30, a mounting plate 31, a servo motor 32, and a transmission assembly 33. The four sides of the bottom of the mounting plate 31 are provided with a bearing seat 30, and the bearing seat 30 is rotationally connected with the first rotating shaft 2. A servo motor 32 is connected to the top left front side of the plate 31 , and a transmission assembly 33 is connected between the output shaft of the servo motor 32 and the front side of the first rotating shaft 2 on the left.

[0067] When the device needs to be moved, start the servo motor 32, the output shaft of the servo motor 32 rotates to drive the transmission assembly 33, the first rotating shaft 2 and the rotating wheel 1 to rotate continuously, and then drives the device to move to the right. When not in use, turn off the servo motor 32 That's it.

[0068] The flushing mechanism 4 includes a first L-shaped rod 40...

Embodiment 3

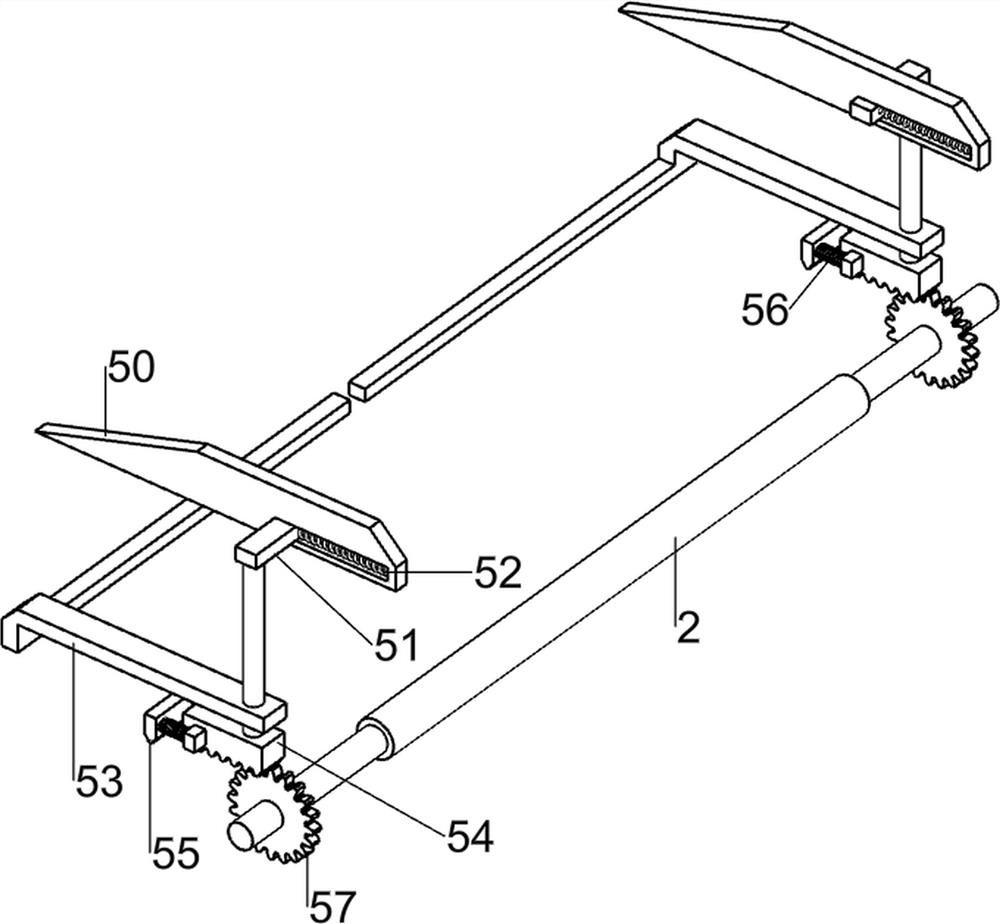

[0071] On the basis of Example 2, such as Figure 4-9 As shown, the opening and closing mechanism 5 is also included, and the opening and closing mechanism 5 includes a first slide rail 50, a slider 51, a first spring 52, a forward rod 53, a first rack 54, a second rack 55, a second rack Spring 56 and the first gear 57, the first slide rail 50 is all connected with the front and rear sides in the middle of the mounting plate 31 top, and slide block 51 is all slidingly connected on the first slide rail 50, the right side of slide block 51 and the first slide rail 50 are provided with the first spring 52, the bottom of the slide block 51 is provided with the advance rod 53, the left side of the advance rod 53 is connected with the baffle plate 43, the right side of the bottom of the advance rod 53 is connected with the first rack 54, the first The left side of the rack 54 is slidably connected with a second rack 55, two second springs 56 are arranged between the right side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com