Mechanical tube cleaner

A pig and mechanical technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as poor sealing of pigging balls and inner walls of pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

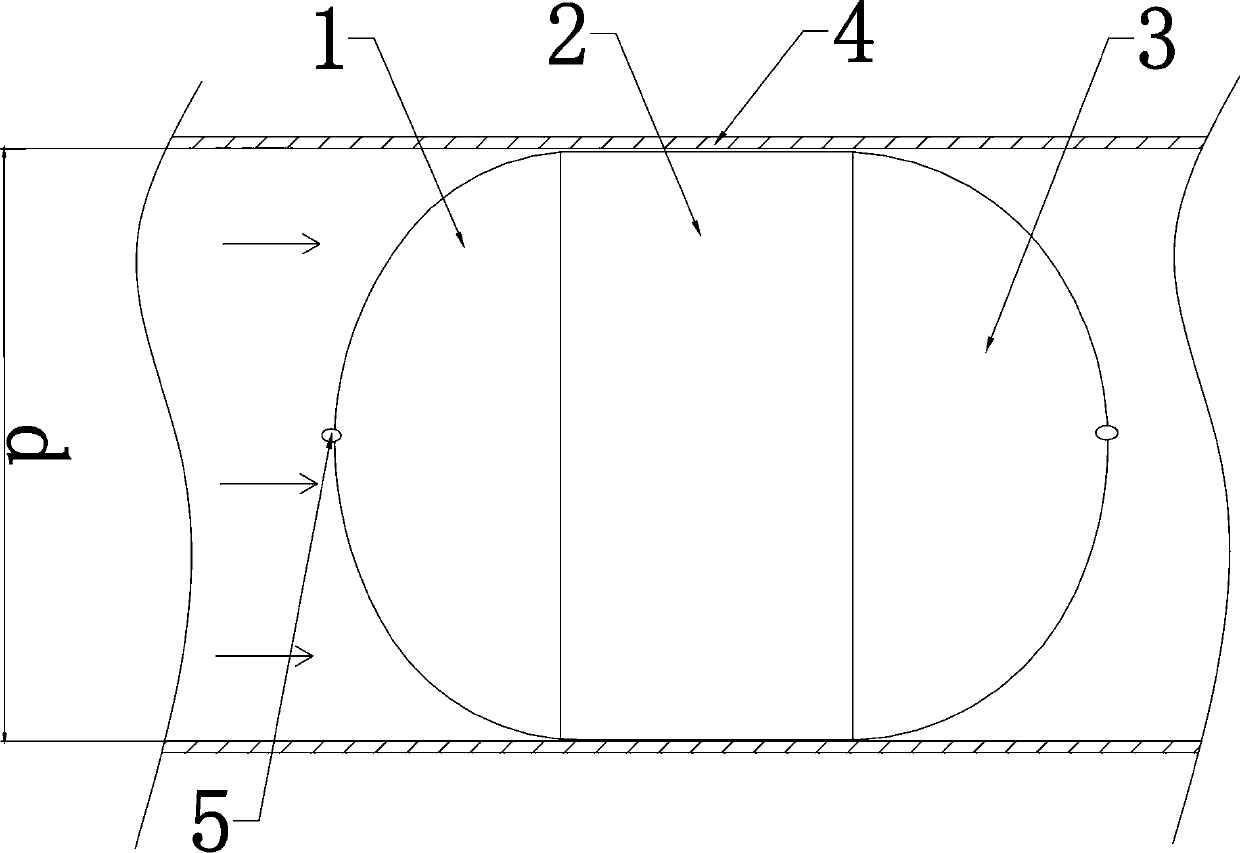

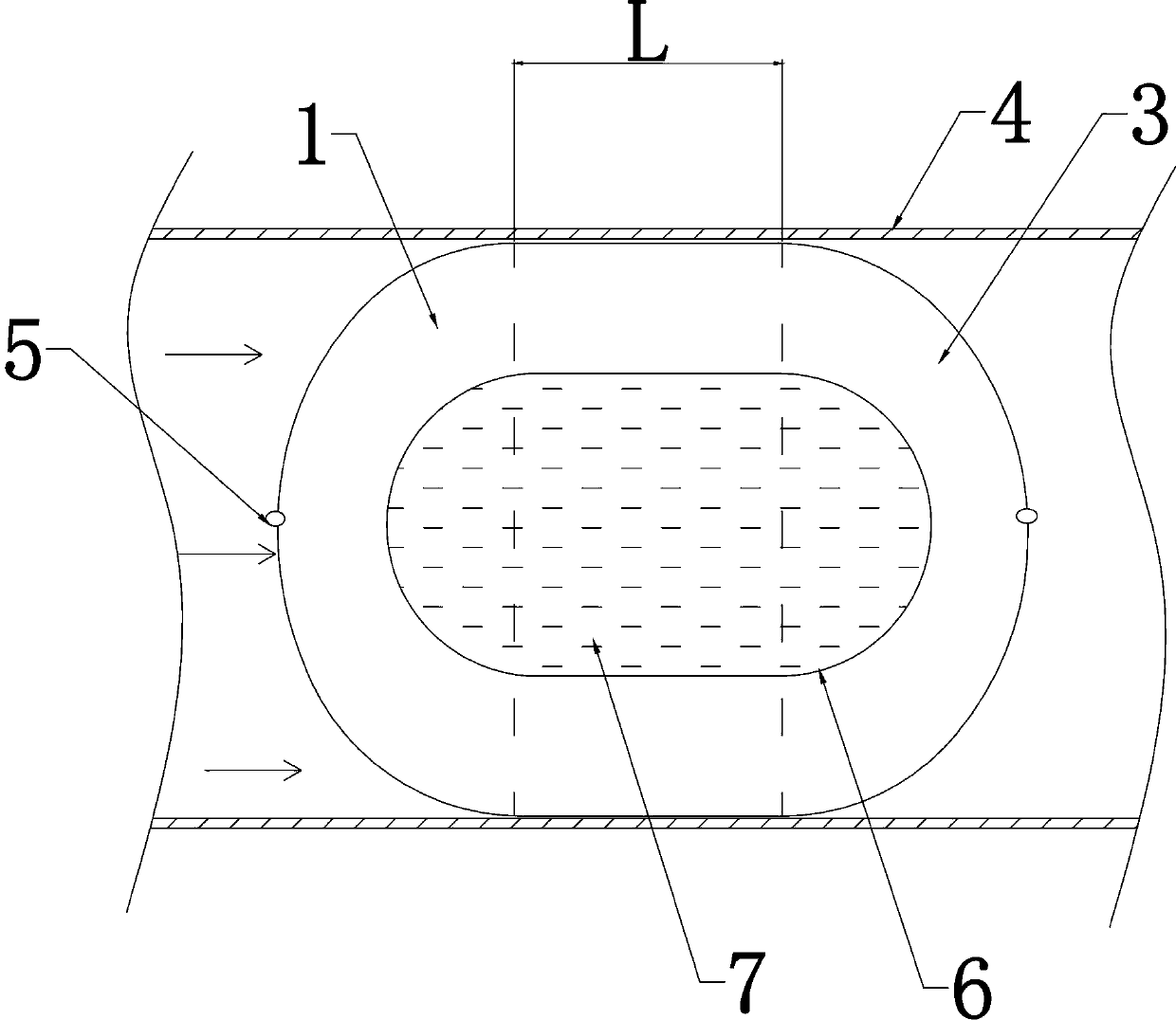

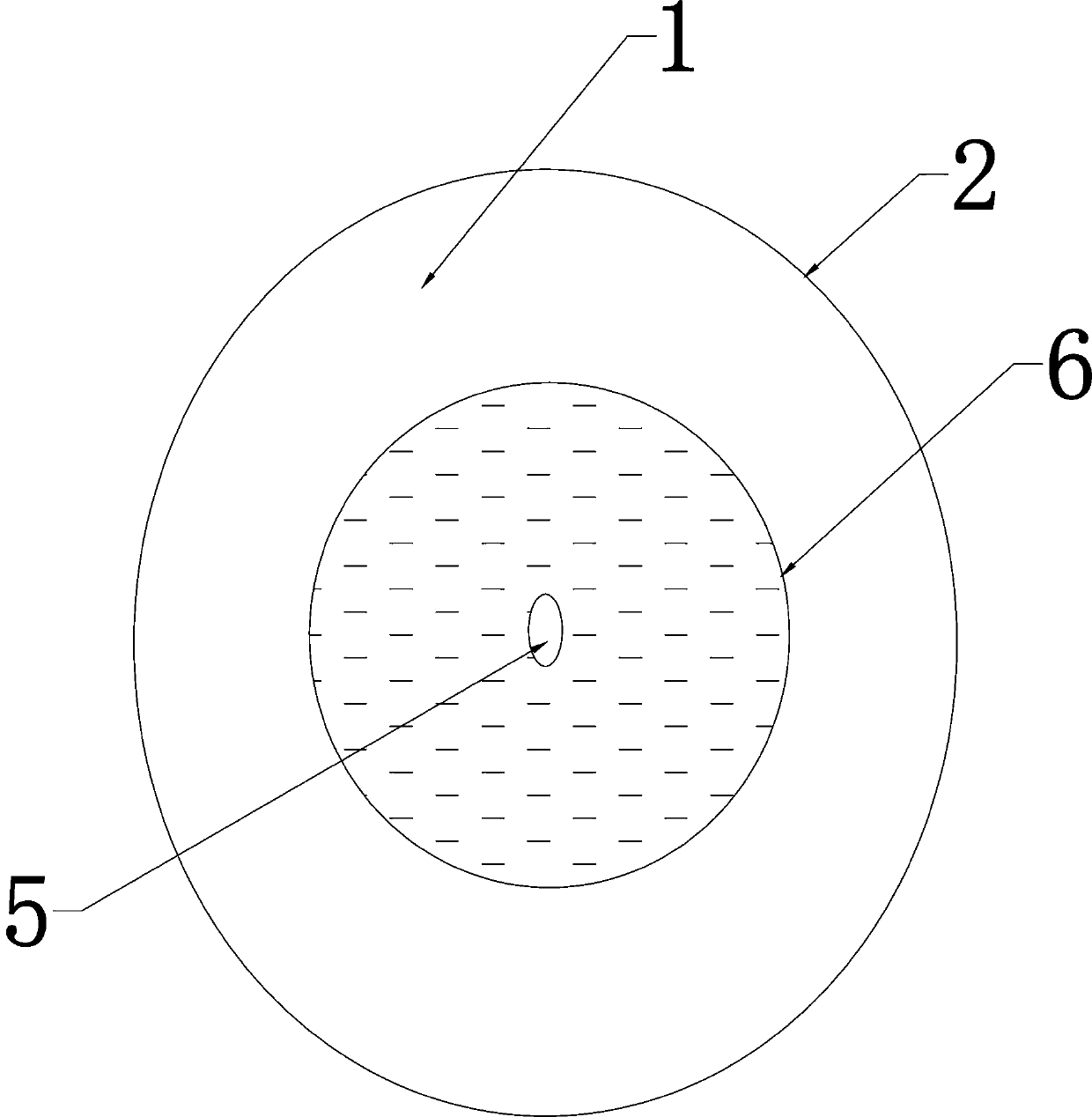

Method used

Image

Examples

Embodiment 1

[0034] For a 14-inch pipeline in a gas field in the South China Sea, in the previous pigging operation, when the low flow rate reached 6.57MMSCFD, the experience of sending 2% and 3% interference balls (cracked when taken out) was experienced.

[0035] Calculation results of the pigging ball for injecting triethylene glycol liquid:

[0036] Table 1-1 Basic data

[0037]

project

value

pipeline

the inside diameter of

337mm

[0038] Table 1-2 Contact strip width

[0039]

[0040] The a and L lengths are calculated by the formula, and they are 68.4mm and 84.4mm at 2% and 3% interference respectively.

[0041] Therefore, the 14-inch pipeline for a certain gas field in the South China Sea can be determined, and the length of the new pig L can be selected between 68.4mm and 84.4mm, which has practical significance. The L length calculated by the formula has better sealing performance, and it is advisable to consider the pipeline passability ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com