Drying agent and preparation method thereof

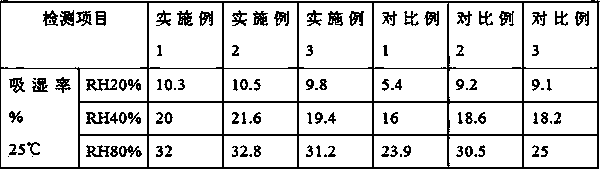

A desiccant and drying technology, which is applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of poor moisture absorption rate of desiccants, and achieve the effects of increased moisture absorption rate, improved network structure, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A preparation method of desiccant, comprising the steps of:

[0028] Take polyvinyl alcohol and add deionized water according to the mass ratio of 1~3:100~150, stir and mix for 20~30min to obtain the soaking liquid, take the water-absorbing active substance according to the mass ratio of 3~7:4~8, add deionized water and mix to obtain Dry the base material, take the dry base material and add the soaking solution according to the mass ratio of 2~5:7~10, let it stand for 18~24h, filter, take the filter residue b to dry, and obtain the desiccant.

[0029] Water-absorbing actives:

[0030] (1) Take guar gum 1:10 and add sodium hydroxide solution with a concentration of 0.06mol / L, stir and mix at 55°C for 40 minutes, then add ammonium persulfate with 3% guar gum mass, and keep warm at 55°C for 10 minutes to obtain stir the mixture;

[0031] (2) In terms of parts by mass, take 25 parts of the stirring mixture, 5 parts of acrylic acid, 6 parts of styrene, and 15 parts of sepi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com