Cleaning and disinfecting method for condensed milk glass bottle

A technology for cleaning and disinfecting glass bottles, which is applied in cleaning methods and utensils, disinfection, chemical instruments and methods, etc. It can solve problems affecting product hygiene risks, unqualified glass bottle disinfection, waste of cleaning water, etc., and avoid air shower cooling , reduce pollution points, good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

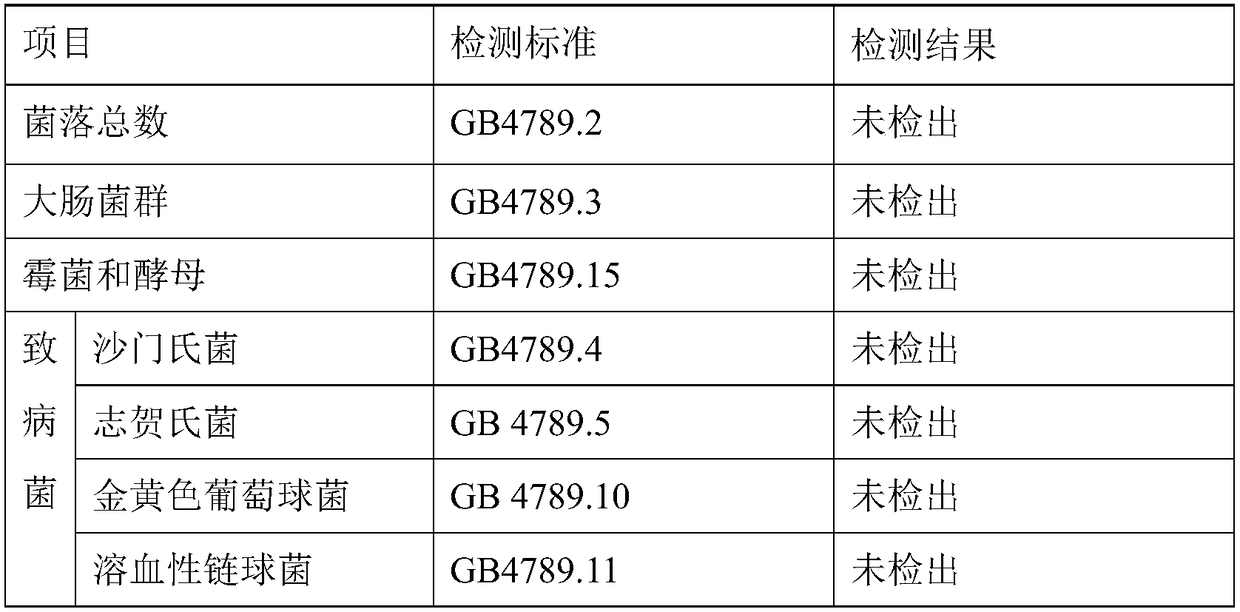

[0039] The specifications of the condensed milk glass bottle are shown in Table 1.

[0040] Table 1 Specifications of Condensed Milk Glass Bottles

[0041] project

index

Mouth capacity, mL

352±10

Empty bottle weight, g

300-330

bottle height, mm

230±1.6

Outer diameter of bottle mouth, mm

26.3±0.3

Inner diameter of bottle mouth, mm

16.3±0.5

62.0±1.5

[0042] Clean and disinfect the condensed milk glass bottles of the specifications described in Table 1. The specific cleaning and disinfection process is as follows:

[0043] Sorting: Check the outer packaging of glass bottles stored in the factory to avoid damage or broken bottles caused by package collapse. If there are any problematic glass bottles to be picked and scrapped, open the outer packaging, check one by one whether there are dirty bottles that are not easy to clean, and classify deal with.

[0044] Pre-cleaning: Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com