High permeability tray type cable bridge

A technology of cable tray and air permeability, which is applied in the direction of electrical components, etc., can solve the problems of poor heat dissipation and affecting the service life of cables, and achieve the effects of improving fire resistance, excellent thermal stability, hardness and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

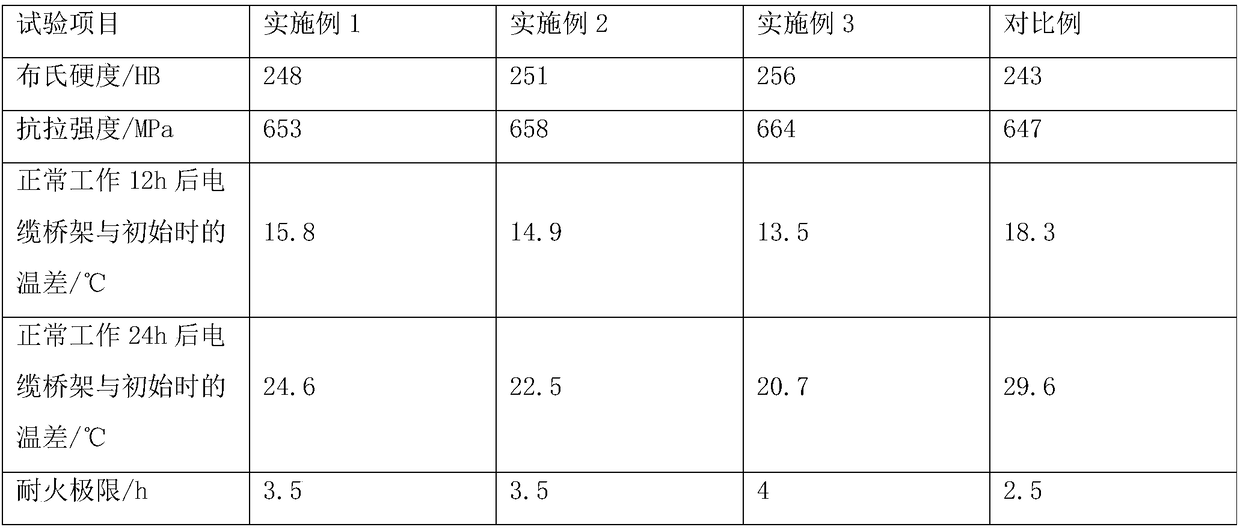

Examples

Embodiment 1

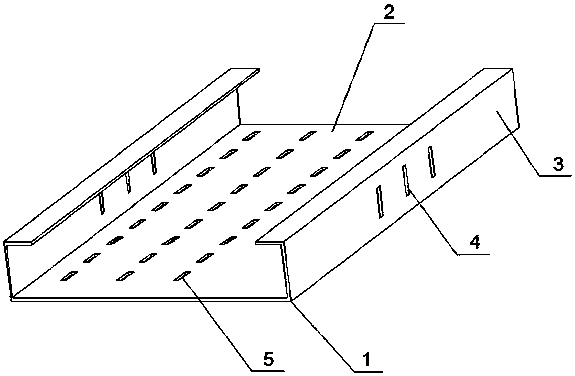

[0029] This embodiment provides a highly air-permeable tray-type cable bridge, including a bridge body 1, the bridge body 1 includes a bottom plate 2 and two side plates 3, the side plates 3 are fixedly connected to both sides of the bottom plate 2, and the bottom plate 2 is connected to the side plates. The board 3 is arranged vertically, and a number of heat dissipation holes 4 are provided on the bottom plate 2 and the sides. The bridge body 1 is covered with a flame-retardant and fire-proof layer, and the flame-retardant and fire-proof layer is covered with a protective layer.

[0030] The composition and mass percentage of bridge body 1 are: C: 0.45%, Si: 0.33%, Mg: 6.4%, Mn: 0.48%, W: 0.14%, Cu: 0.39%, Fe: 1.9%, Cr: 3.55 %, V: 0.36%, La: 0.035%, Er: 0.055%, Ce: 0.018%, and the balance is Al and unavoidable impurities.

[0031] The raw material components of the flame retardant and fireproof layer include by weight: 5 parts of expandable graphite, 12 parts of aluminum hyd...

Embodiment 2

[0041] This embodiment provides a highly air-permeable tray-type cable bridge, including a bridge body 1, the bridge body 1 includes a bottom plate 2 and two side plates 3, the side plates 3 are fixedly connected to both sides of the bottom plate 2, and the bottom plate 2 is connected to the side plates. The board 3 is arranged vertically, and a number of heat dissipation holes 4 are provided on the bottom plate 2 and the sides. The bridge body 1 is covered with a flame-retardant and fire-proof layer, and the flame-retardant and fire-proof layer is covered with a protective layer.

[0042]The composition and mass percentage of bridge body 1 are: C: 0.53%, Si: 0.37%, Mg: 6.9%, Mn: 0.53%, W: 0.17%, Cu: 0.43%, Fe: 3.4%, Cr: 3.76 %, V: 0.45%, La: 0.040%, Er: 0.060%, Ce: 0.021%, and the balance is Al and unavoidable impurities.

[0043] The raw material components of the flame retardant and fireproof layer include, by weight, 9 parts of expandable graphite, 18 parts of aluminum hyd...

Embodiment 3

[0053] This embodiment provides a highly air-permeable tray-type cable bridge, including a bridge body 1, the bridge body 1 includes a bottom plate 2 and two side plates 3, the side plates 3 are fixedly connected to both sides of the bottom plate 2, and the bottom plate 2 is connected to the side plates. The board 3 is arranged vertically, and a number of heat dissipation holes 4 are provided on the bottom plate 2 and the sides. The bridge body 1 is covered with a flame-retardant and fire-proof layer, and the flame-retardant and fire-proof layer is covered with a protective layer.

[0054] The composition and mass percentage of bridge body 1 are: C: 0.49%, Si: 0.35%, Mg: 6.6%, Mn: 0.51%, W: 0.15%, Cu: 0.41%, Fe: 2.6%, Cr: 3.65 %, V: 0.41%, La: 0.038%, Er: 0.057%, Ce: 0.019%, and the balance is Al and unavoidable impurities.

[0055] The raw material components of the flame retardant and fireproof layer include, by weight: 7 parts of expandable graphite, 15 parts of aluminum hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com