OLED display panel and encapsulation method thereof

A display panel and encapsulation layer technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problem of water vapor/oxygen intrusion into devices, and achieve enhanced water vapor/oxygen entry into OLED display panels, saving costs, The effect of increasing the border width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

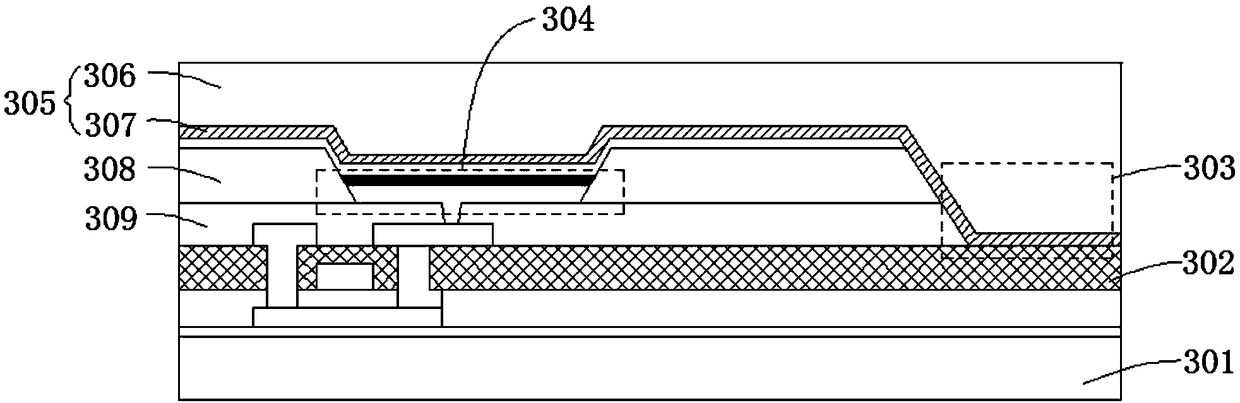

[0044] In the second embodiment, the first layer on the inner surface of the encapsulation layer 305 is an inorganic layer, and the space between the reserved area 303 and the encapsulation layer 305 is reserved in the manufacture of each film layer and structure included in the thin film transistor layer. The first inorganic layer 307 is in contact, that is, when the flat layer 309, the pixel defining layer 308 and other organic material film layers are produced, the reserved area 303 is vacant or has a hole, and when the package is produced, In this embodiment, the first inorganic layer 307 of the encapsulation layer 305 is in contact with the second inorganic material film layer in the thin film transistor layer in the reserved area 303 to form the enhanced encapsulation enclosing circle of inorganic materials. .

[0045] Such as Figure 4A As shown, it is a schematic cross-sectional view of an edge part of an OLED display panel provided by Embodiment 3 of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com