Method for quickly assembling and adjusting axisymmetric telescope with image plane as datum

An assembly and adjustment method and telescope technology, applied in telescopes, optics, instruments, etc., can solve the problems of high working environment requirements, sensitive environmental factors, and high tool precision, and achieve the effects of easy portability and transportation, simple overall structure, and good visualization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Examples of the present invention are described below. But following embodiment only limits to explain the present invention, and protection scope of the present invention should comprise the whole content of claim, and promptly can realize the whole content of claim of the present invention to those skilled in the art through following embodiment.

[0027] The invention fully utilizes the characteristics of the high-precision rotary mechanism and the axisymmetric telescope, and has simple process, easy realization and high precision.

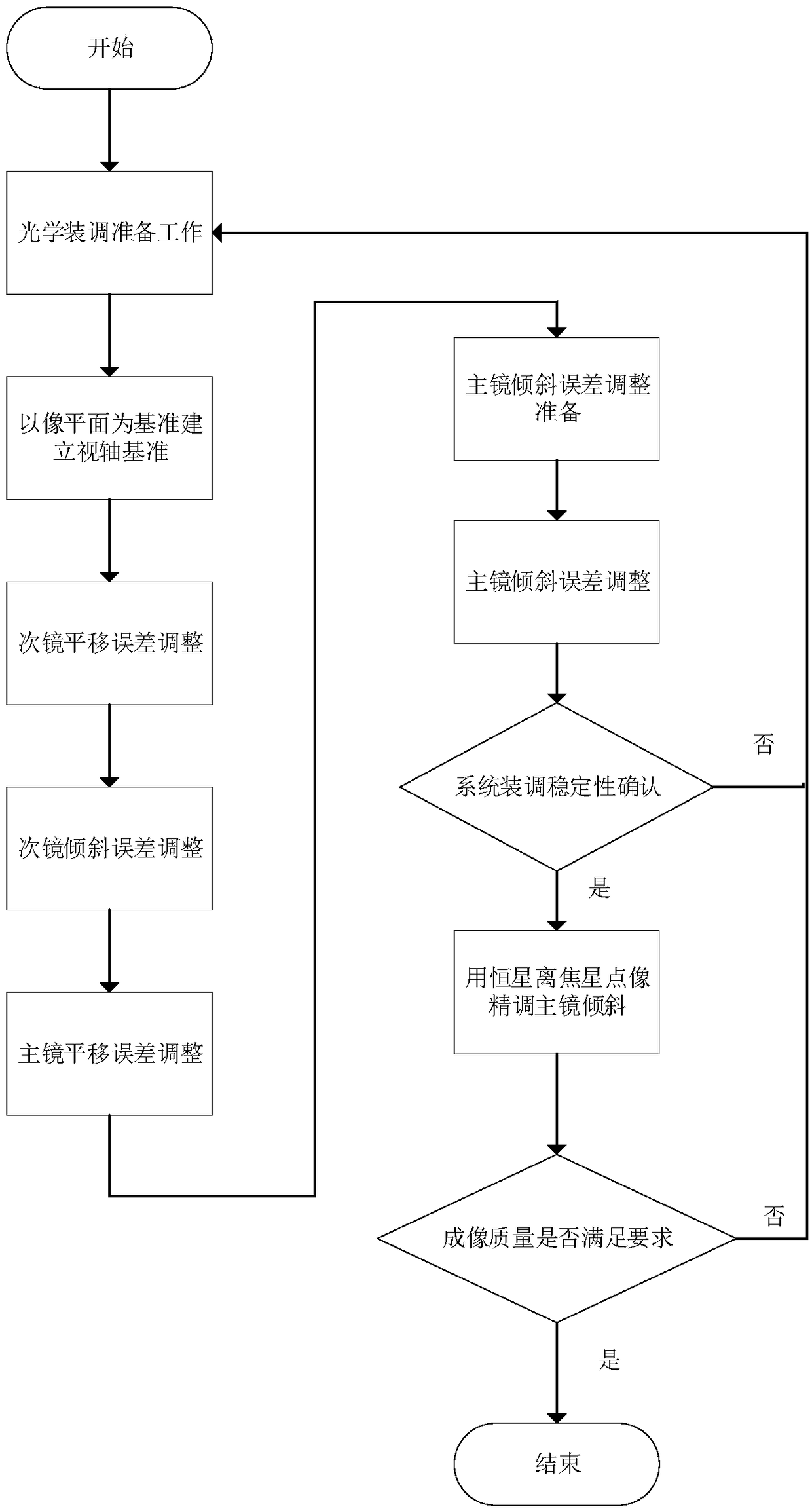

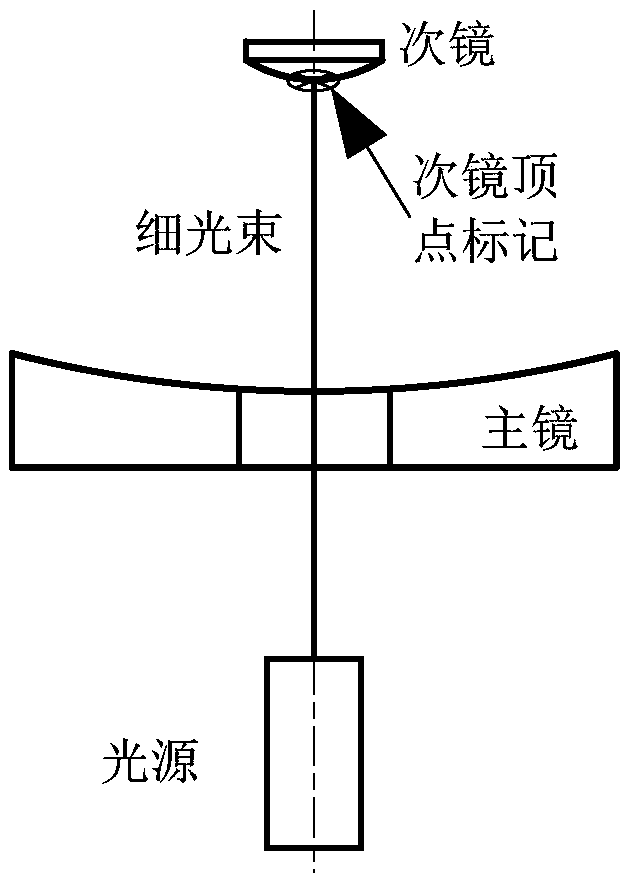

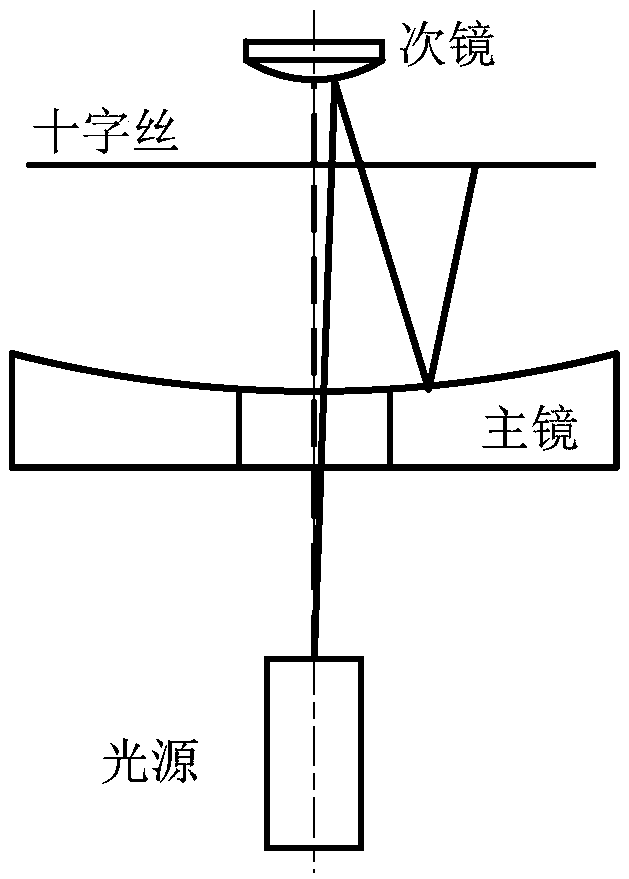

[0028] The optical adjustment tool used in the present invention includes parts such as high-precision rotary structure, observation window, high-precision tilt adjustment mechanism and low divergence angle laser, and the specific structure is as follows figure 1 shown. The set-up tool is attached near the installation image plane via a precision-fit adapter. Utilizing the rotary characteristics of the high-precision rotary mechanism, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com