Fixing device for metal sheet high temperature tensile extensometer

A technology of thin metal plates and fixing devices, applied in the direction of measuring devices, applying stable tension/pressure to test material strength, instruments, etc., to achieve the effects of convenient operation, low manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

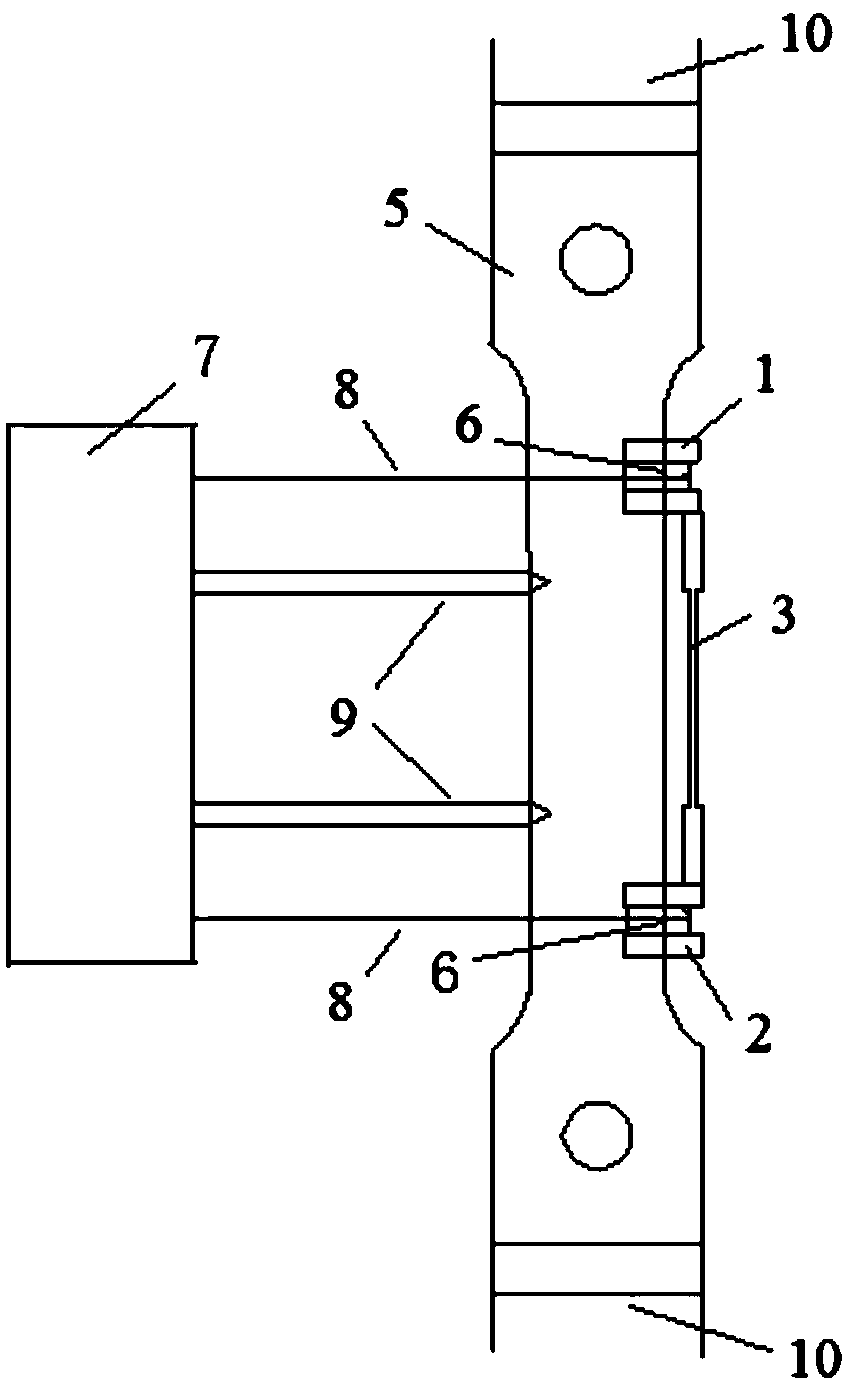

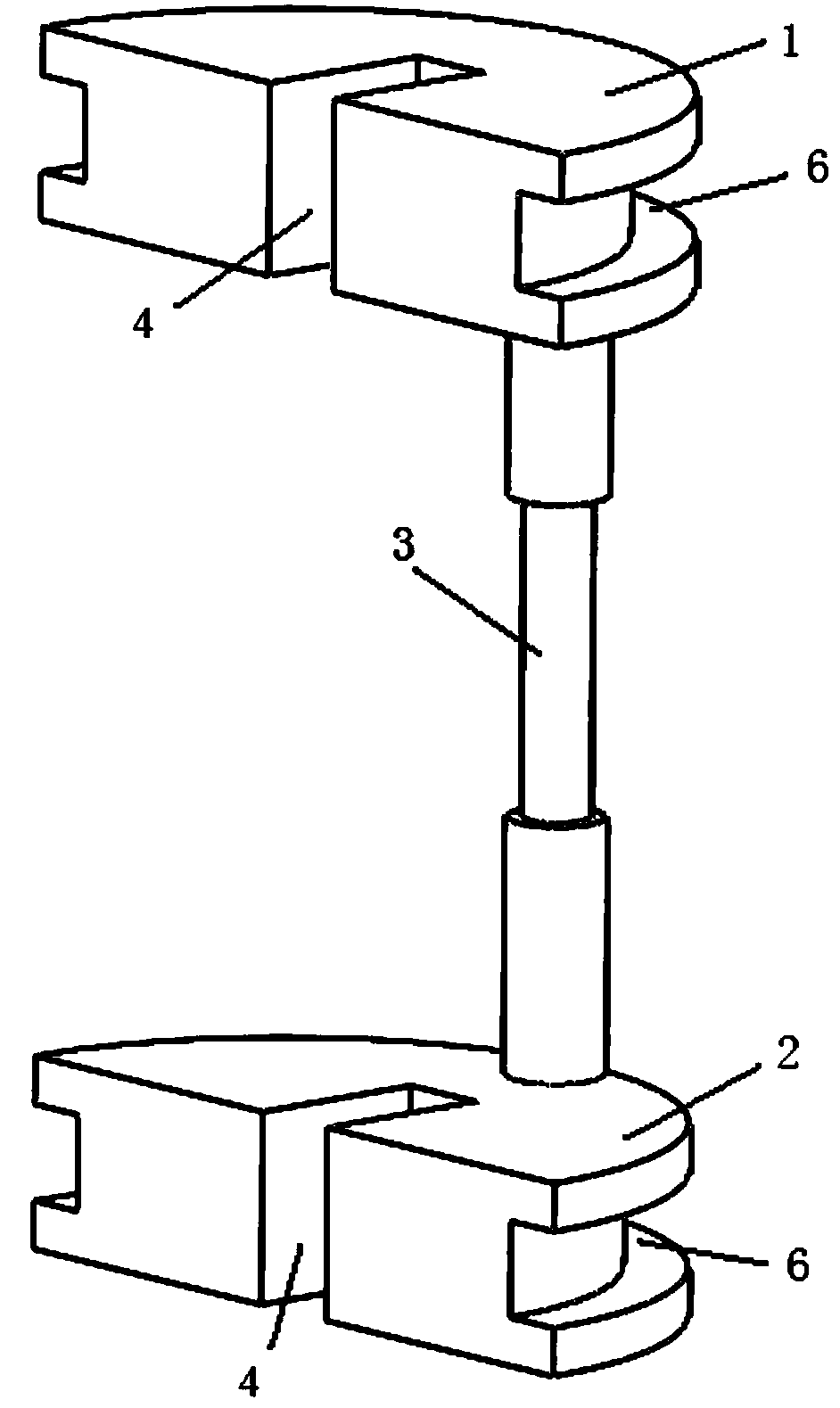

[0016] The device of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments:

[0017] See attached Figure 1~2 As shown, the fixing device of this kind of metal sheet high temperature tensile extensometer is characterized in that: the device includes an upper clamping block 1 and a lower clamping block 2 with the same shape and structure, and the upper clamping block 1 and the lower clamping block 2 are connected by the sleeve guide rod 3, the height of the sleeve guide rod 3 is adjustable to adapt to the fixation of the sample 5 with different gauge lengths, the two clamping blocks are in the shape of a semicircle, and the upper clamping block 1 The vertical through groove 4 is processed on the side plane of the lower clamping block 2, the sample 5 is inserted in the through groove 4 of the upper clamping block 1 and the lower clamping block 2, the upper clamping block 1 and the lower clamping block The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com