Automatic laser detection device and method for automobile curved glass

A curved glass, automatic detection technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of low measurement efficiency, missed detection of defective products, total reflection, etc., and achieve reasonable structural design, high precision and effect, and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

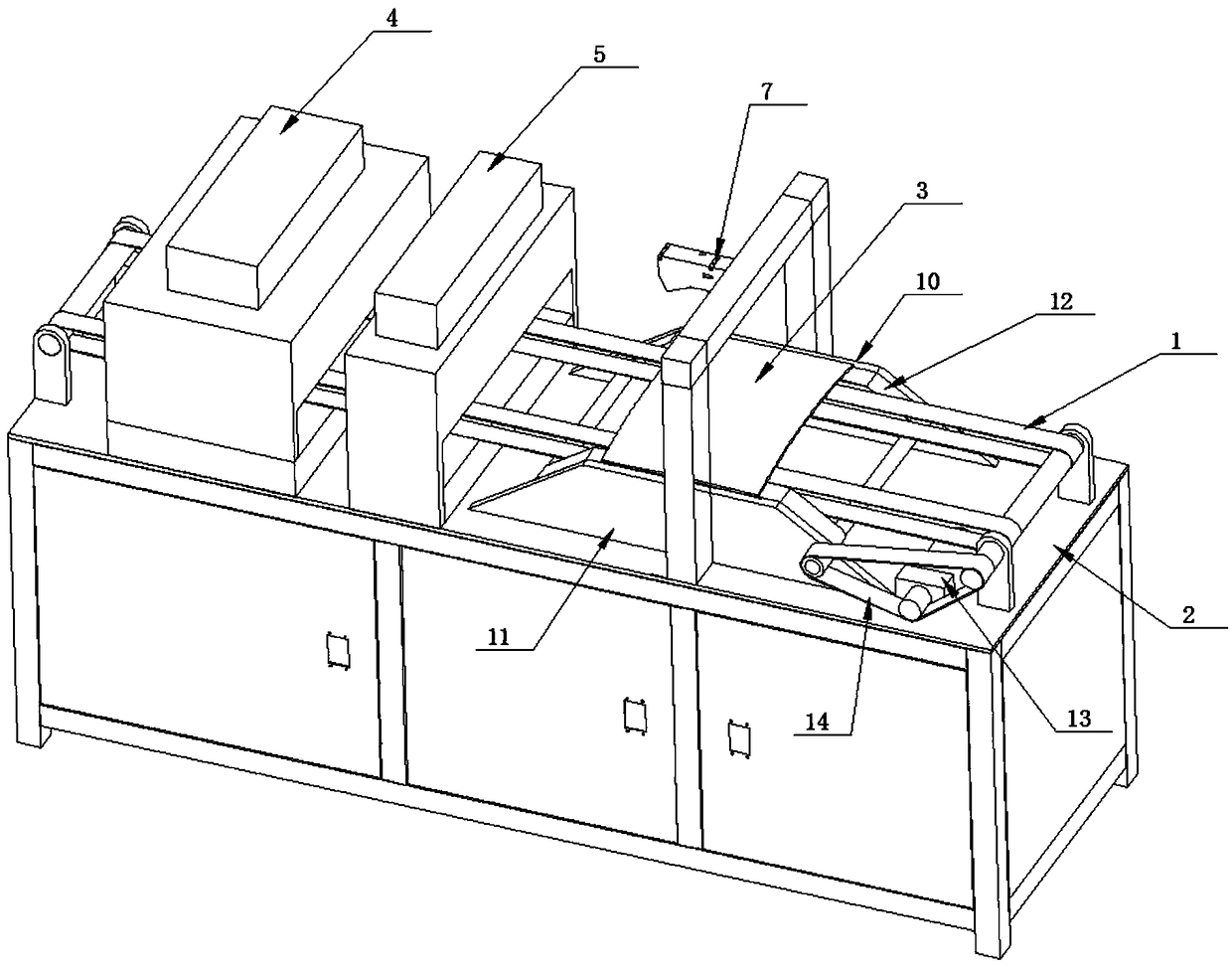

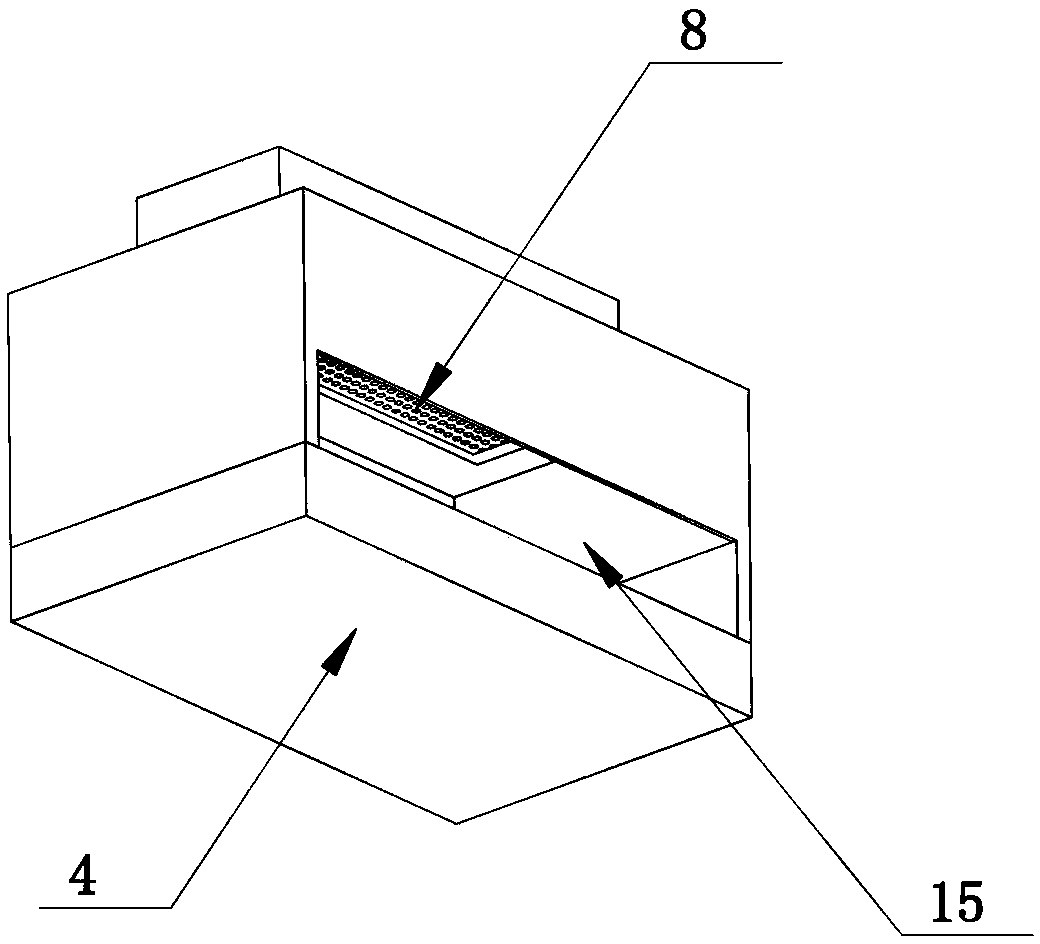

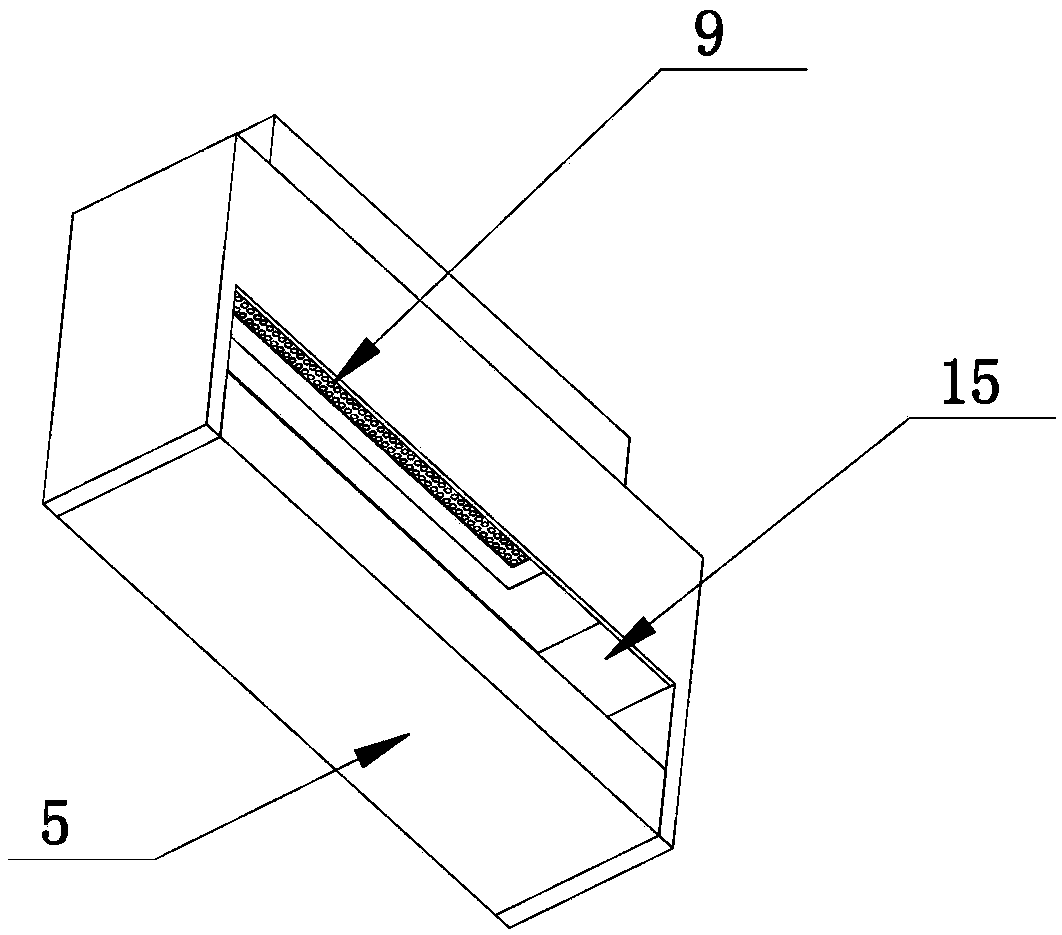

[0031] refer to Figure 1 to Figure 5 , the present invention provides a kind of automatic laser detection equipment and detection method of automobile curved surface glass, the automatic laser detection equipment of automobile curved surface glass comprises: a first conveyor belt 1, the first conveyor belt 1 is installed on a workbench 2, and is used to place and transmit glass workpieces 3 The cooling air injection unit 4 is used to blow cold air on the upper surface of the glass workpiece 3 on the first conveyor belt 1; the heating air injection unit 5 is used to perform cooling on the upper surface of the glass workpiece 3 delivered by the cooling air injection unit Blowing hot steam to form a mist layer 6 on the upper surface of the glass workpiece 3; the laser detection unit 7 is used to perform laser scanning detection on the mist layer 6 and output detection data. The laser source used by the laser detection unit 7 is Keyence Laser, the upper surface of the glass workp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com