A swash plate compressor speed measuring device

A technology of a speed measuring device and a compressor, which is applied in the field of compressors, can solve the problems of reducing the strength of the shell and the swash plate, affecting the working efficiency of the compressor, and stopping the work of the compressor, so as to achieve less structural changes, easy promotion into the market, The effect of increasing the upgrade speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

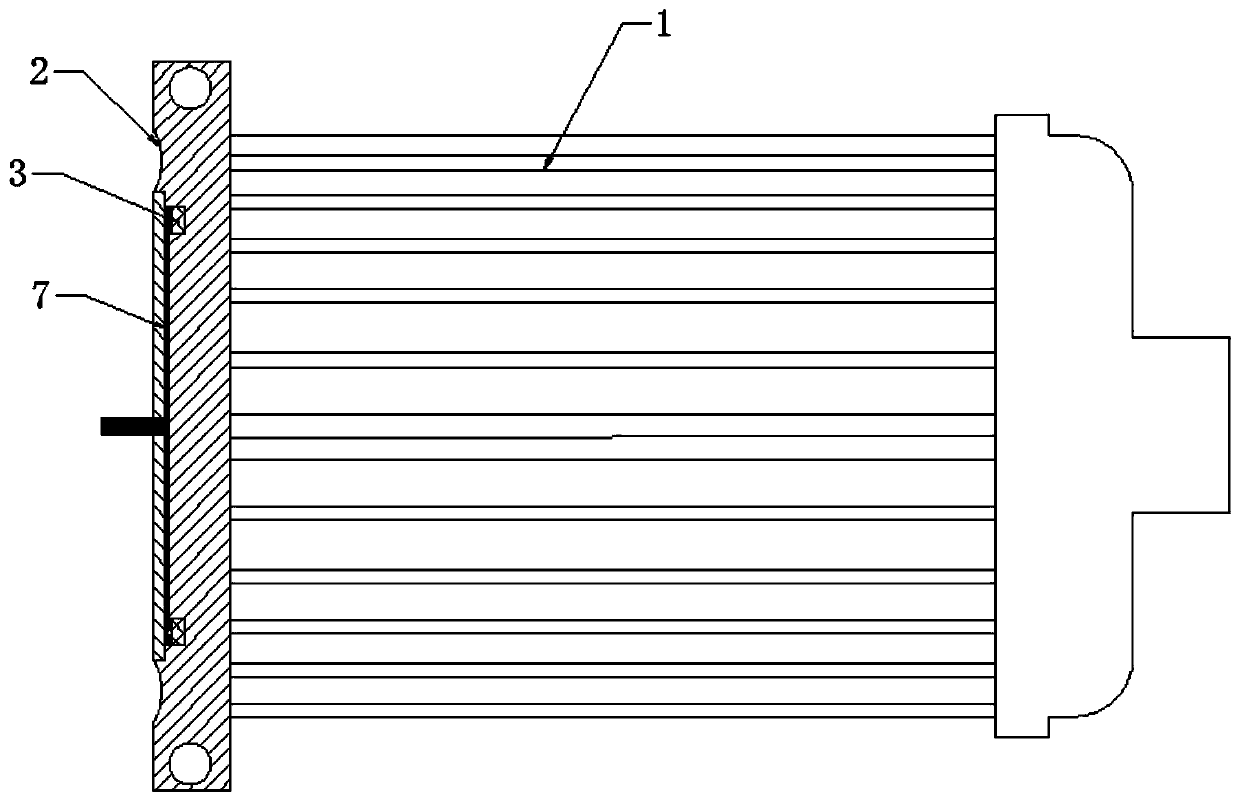

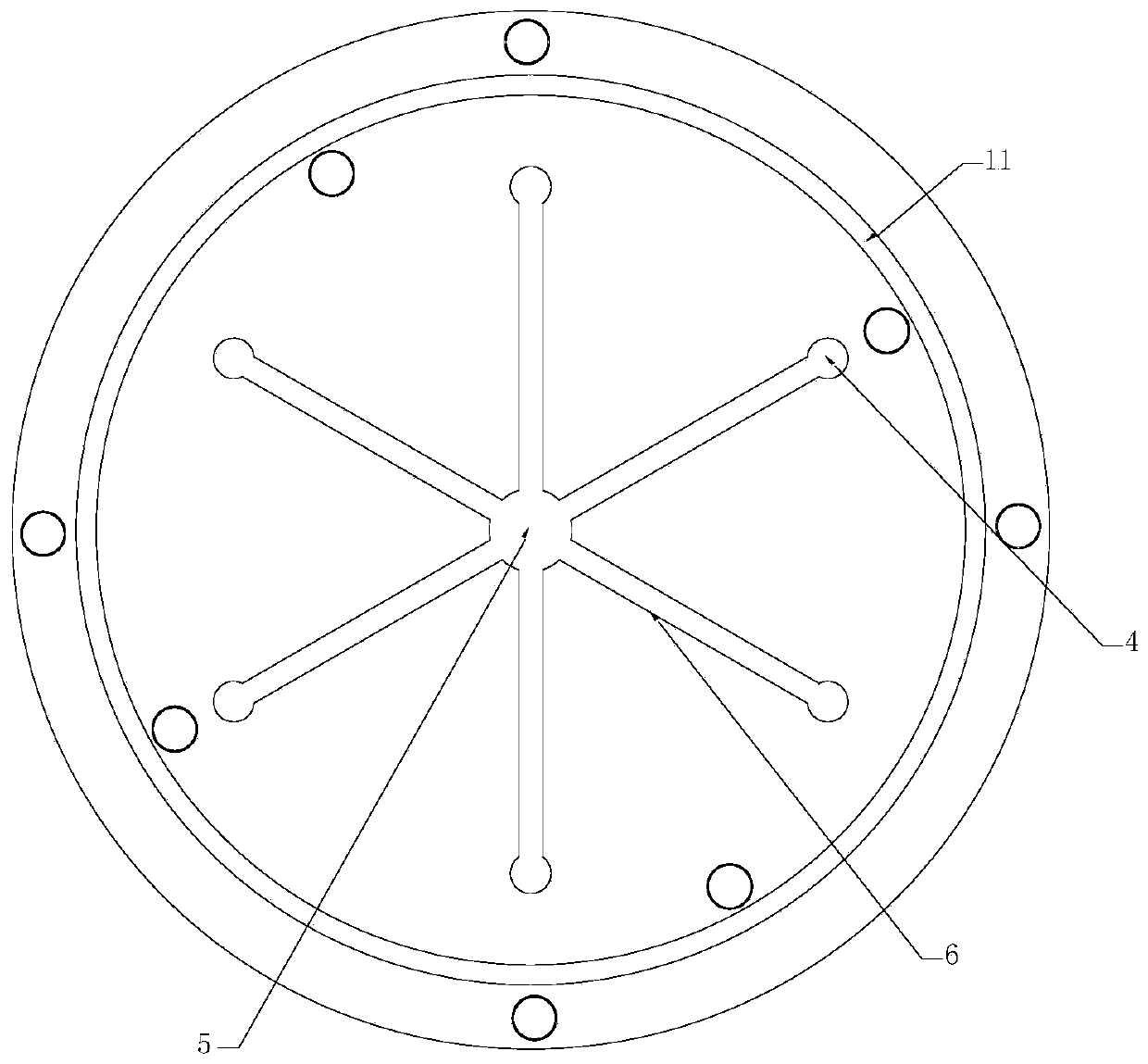

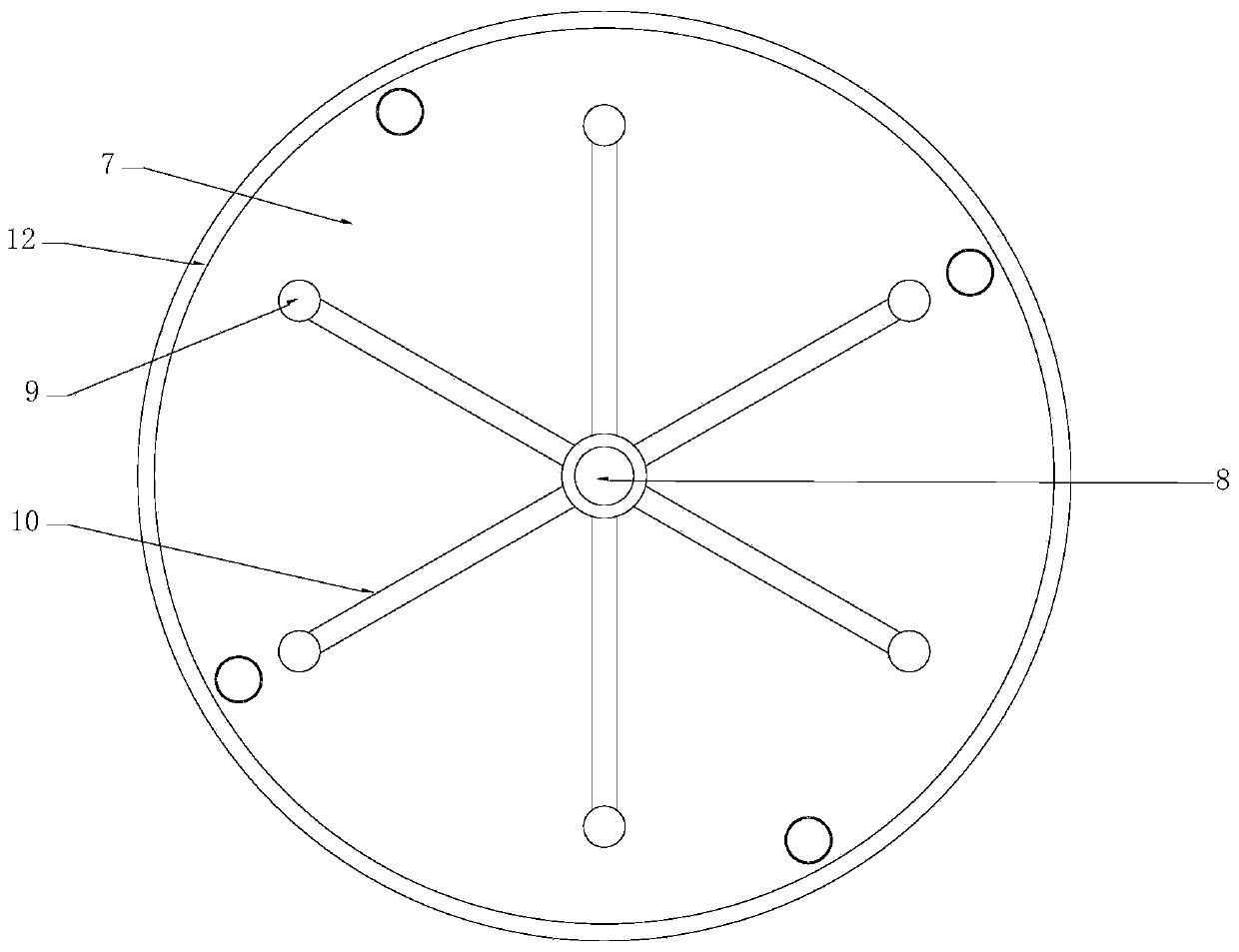

[0020] This embodiment provides a swash plate type compressor speed measuring device, which is installed on a compressor 1 provided with a pump body, a main shaft, and a swash plate fixed on the main shaft, and the end of the compressor 1 is also fixedly connected with a mounting seat 2 It also includes a fixed structure and a magnetic sensor 3. The symmetrical ends of the swash plate are provided with magnetized regions 1 and 2 with opposite polarities generated by the magnetization machine. The magnetized region 1 and the magnetized region 2 include the The front and back of the magnetized end and the side connecting the front and the back, the cross-sections of the magnetized area 1 and the magnetized area 2 are both rectangular, the compressor 1 is installed on the front of the mounting base 2, and the back of the mounting base 2 is installed A plurality of installation blind holes 4 are evenly distributed on the concentric circle with the center of the seat 2 as the center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com