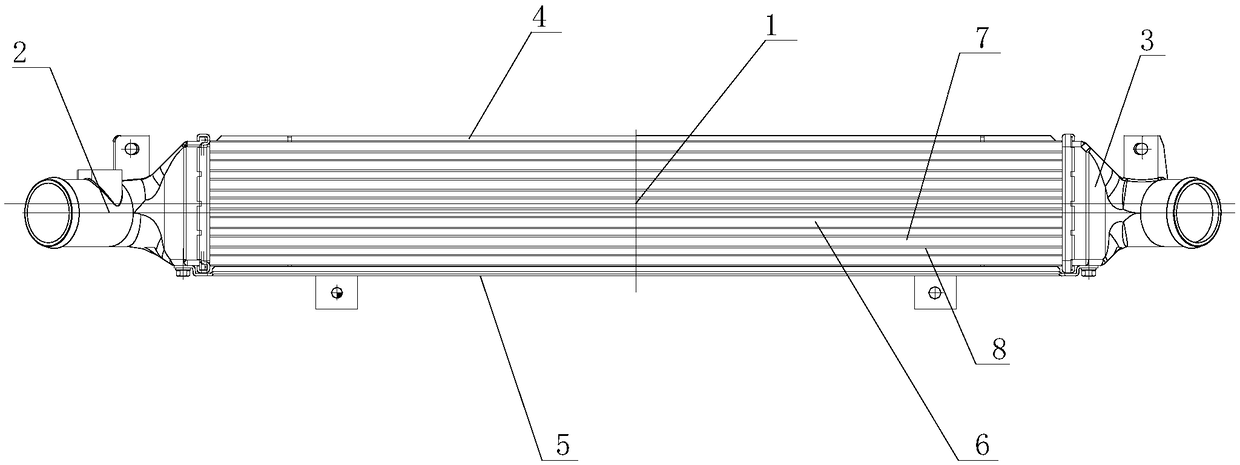

High-performance and low-energy-consumption intercooler and manufacturing method thereof

A low-energy, high-performance technology, used in machines/engines, internal combustion piston engines, mechanical equipment, etc., can solve problems such as reliability and consistency not guaranteed, achieve low labor costs and quality costs, and improve corrosion resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0045] The present invention also provides a method for manufacturing the above-mentioned high-performance and low-energy consumption intercooler, comprising the following steps:

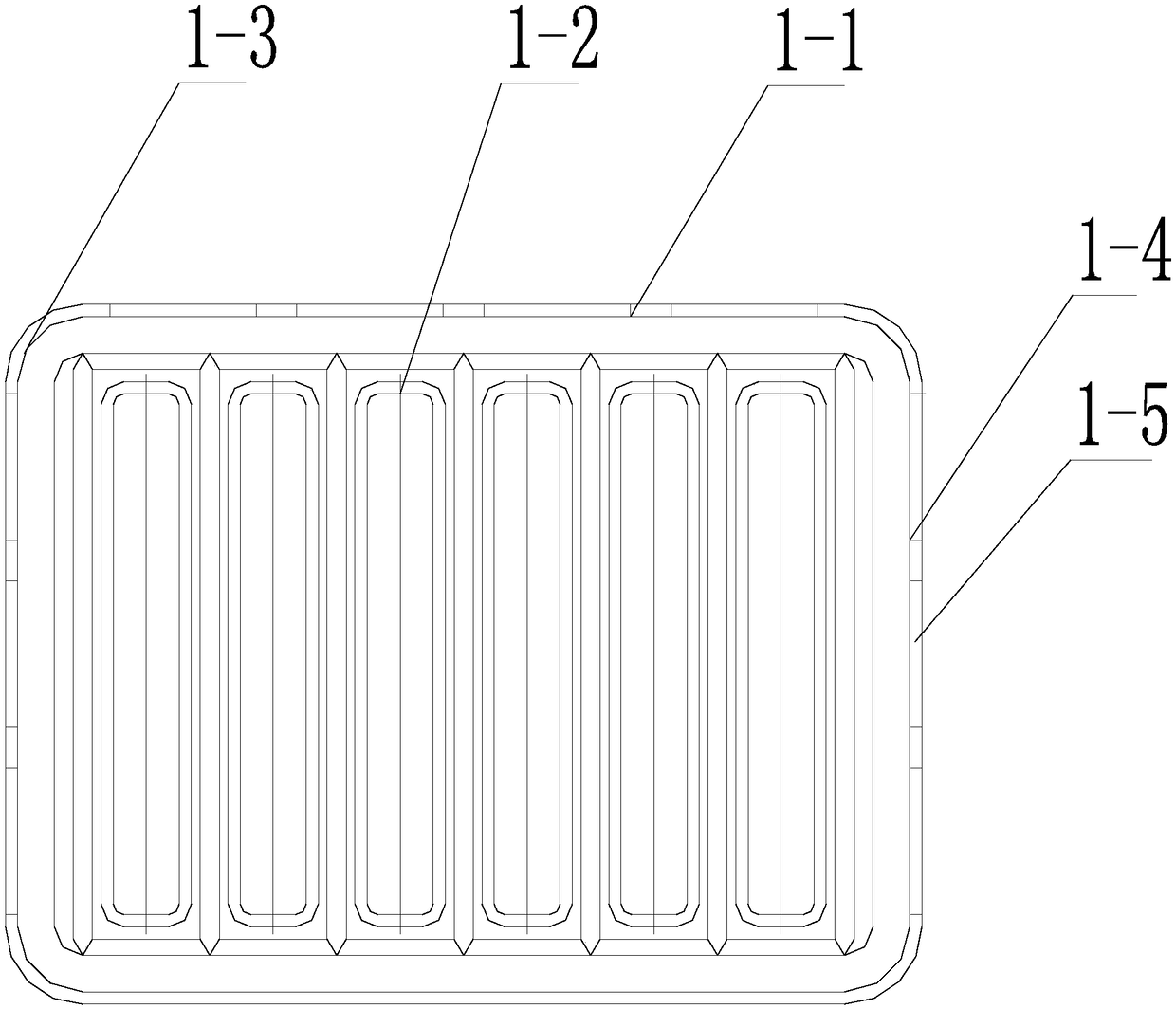

[0046] Step 1: Process the main board, baffle, and side panels: select a square aluminum plate as the original processing board, and process the original processing board into corresponding parts according to the structure and shape of the mold in the form of stamping to ensure that the parts do not have any stamping cracks, cracks and The 4343 alloy brazing layer on the surface is damaged, and then the surface of the component is degreased, purified and dried;

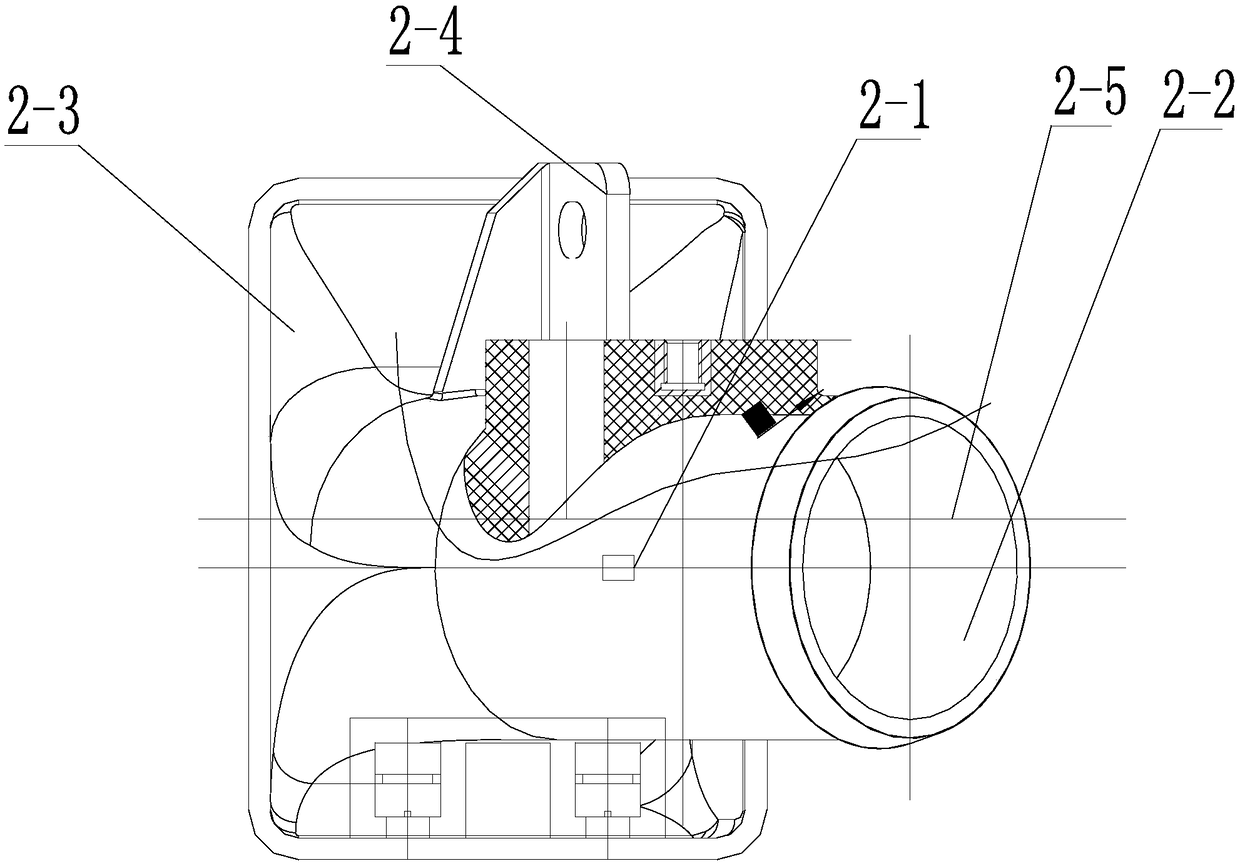

[0047] Step 2: Process the left air chamber: select the material as BASF A3W2GH10, glass fiber reinforced heat-stabilized polyamide 66, and its glass fiber content is 50% to 52% as the raw material. The pretreatment of the parts is not less than 48 hours. Check the water content of the pretreated finished parts. The water content standard i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com