Bond-type gas well opening slow-plugging device and application method thereof

A technology of ties and gas wells, applied in wellbore/well valve devices, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of difficult management and maintenance of gas wells, save manpower and material resources, reduce maintenance difficulty, The effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

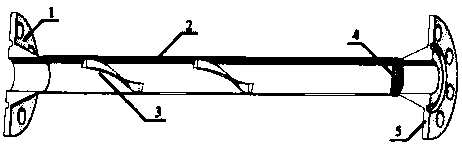

Embodiment 1

[0021] When opening a gas well in a gas field, when the pressure is high, the needle valve must be manually operated to throttle and reduce the pressure when opening the well, so as to prevent the downstream pipeline pressure of the needle valve from exceeding the designed pressure of 6.3MPa, because the throttling process is inevitably When there is a cooling phenomenon, a certain amount of hydrate will be gradually generated in the wellhead pipeline downstream of the needle valve, and due to the throttling and cooling phenomenon of the wellhead needle valve during the well opening process, part of the hydrate particles formed by the well opening will go down with the airflow and block the wellhead surface The swirling flowmeter downstream of the pipeline caused ice blockage in the pipeline. In order to solve the ice blockage of the pipeline and clear the pipeline, this embodiment provides a tie-type gas well opening and plugging prevention device, such as figure 1 As shown, th...

Embodiment 2

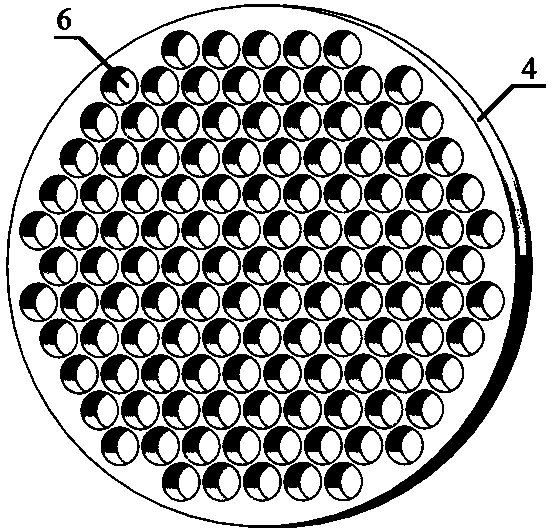

[0027] On the basis of Example 1, such as figure 1 with image 3 As shown, the inner cavity of the oil pipe 2 is also provided with a hydrate filter disc 4, and the hydrate filter disc 4 is placed in the downstream inner cavity of the oil pipe 2 perpendicular to the central axis of the oil pipe 2 and located downstream of the tie-type vortex generator 3.

[0028] The working process and working principle of the tie-in gas well opening and blocking device are as follows;

[0029] The tie-type gas well opening and plugging relief device is connected between the gas well needle valve and the gas well flow meter. When the gas well is opened, extreme low temperature is generated in the wellhead pipeline downstream of the needle valve, hydrate is formed in the pipeline, and the hydrate gradually grows. The tie-type vortex generator 3 induces the airflow in the pipeline to generate a relatively regular vortex flow pattern, and uses the purge characteristics of the vortex, Enhance the air...

Embodiment 3

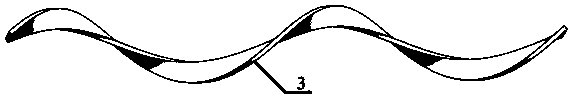

[0031] On the basis of Example 2, such as figure 2 As shown, the tie-type vortex generator 3 has a wavy tie-like structure, and the wavy tie-like structure has a plurality of vortex waveform periods, and the waveform of each vortex waveform period is twisted. The angle between the tangent to the outer edge of the tie of the tie type vortex generator 3 and the central axis of the oil pipe 2 is 50 degrees. The tethered vortex generator 3 has two vortex waveform periods.

[0032] The tie-type vortex generator 3 can induce the airflow in the pipeline to produce a relatively regular vortex flow pattern, and utilize the purging characteristics of the vortex to enhance the airflow carrying liquid, reduce the adhesion of liquid phase on the pipe wall, and alleviate the formation of hydrate particles. And the grown hydrate particles are stripped from the pipe wall and blown downstream to prevent them from long-term attachment to the pipe wall downstream of the needle valve and continue t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com