Integral construction method of sealing and curing agent wear resistant floor

A sealing and curing agent, the overall construction technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of inability to use laser leveling machines effectively, complex and changeable shapes, and many indoor comprehensive pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099] A concrete sealing and curing agent wear-resistant floor overall construction method, comprising the following steps:

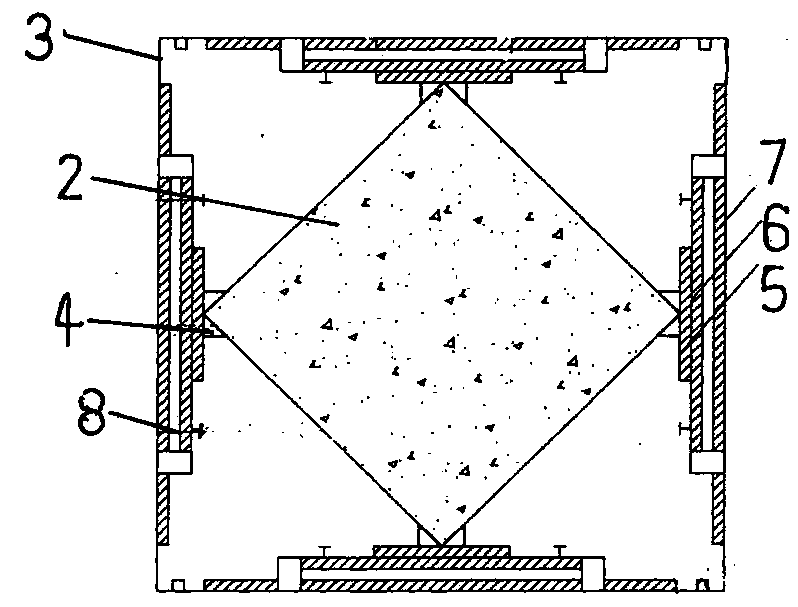

[0100] (1) Tool-based mold design

[0101] (1) Standardized elevation control mold for screw angle steel

[0102] Use Φ14mm long screw rod as the height control adjustment bolt, set two screw caps on the upper part, sandwich the angle steel between the two screw caps, the lower screw cap adjusts the height, and the upper screw cap fixes the angle steel;

[0103] The elevation control component adopts 6m long L30×30×4 angle steel, the upper part is drilled with Φ16mm holes, and the bolt support spacing is arranged according to 1900mm;

[0104] Set the size of the ground sub-storage according to the column net spacing, set the expansion joints according to the column center or column net spacing, and determine the angle steel spacing as 4-6m;

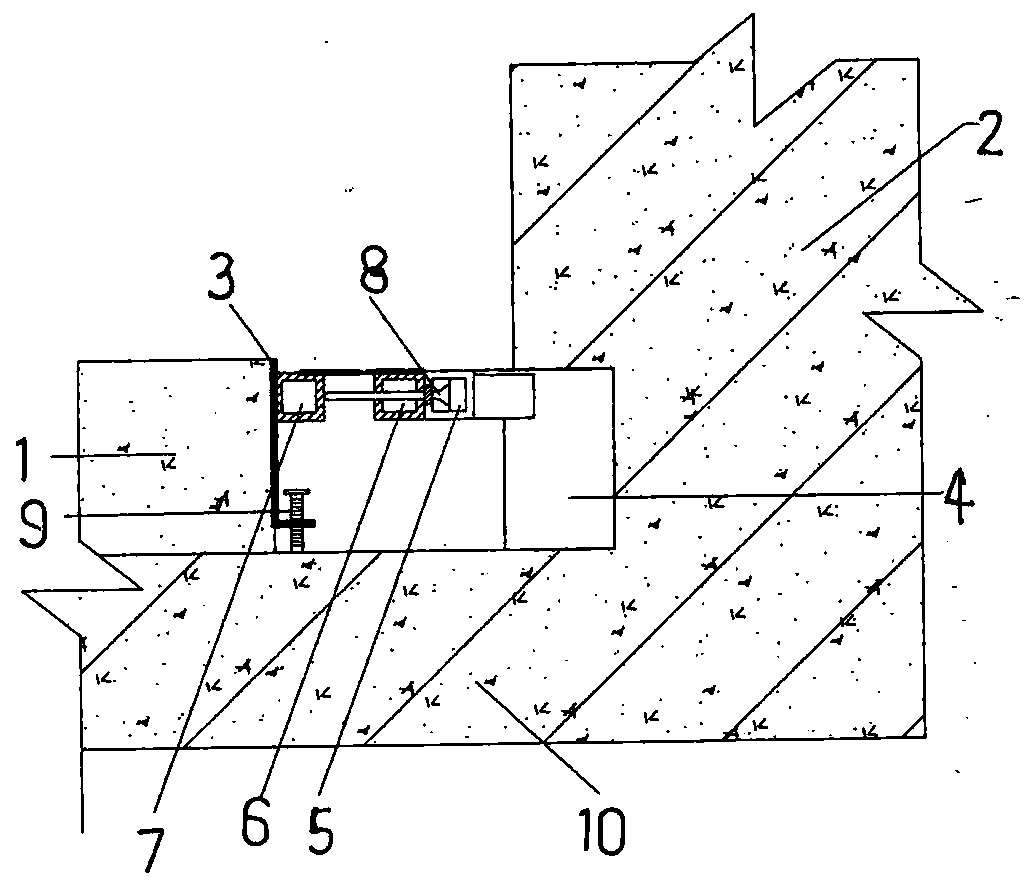

[0105] (2) Tool template for construction joints around columns

[0106] The reserved area around the column...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com