Reservoir sedimentation silt pumping system and method

A suction system, sediment technology, applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., can solve the problem that it is difficult to apply, self-priming pipeline cannot effectively suck sediment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

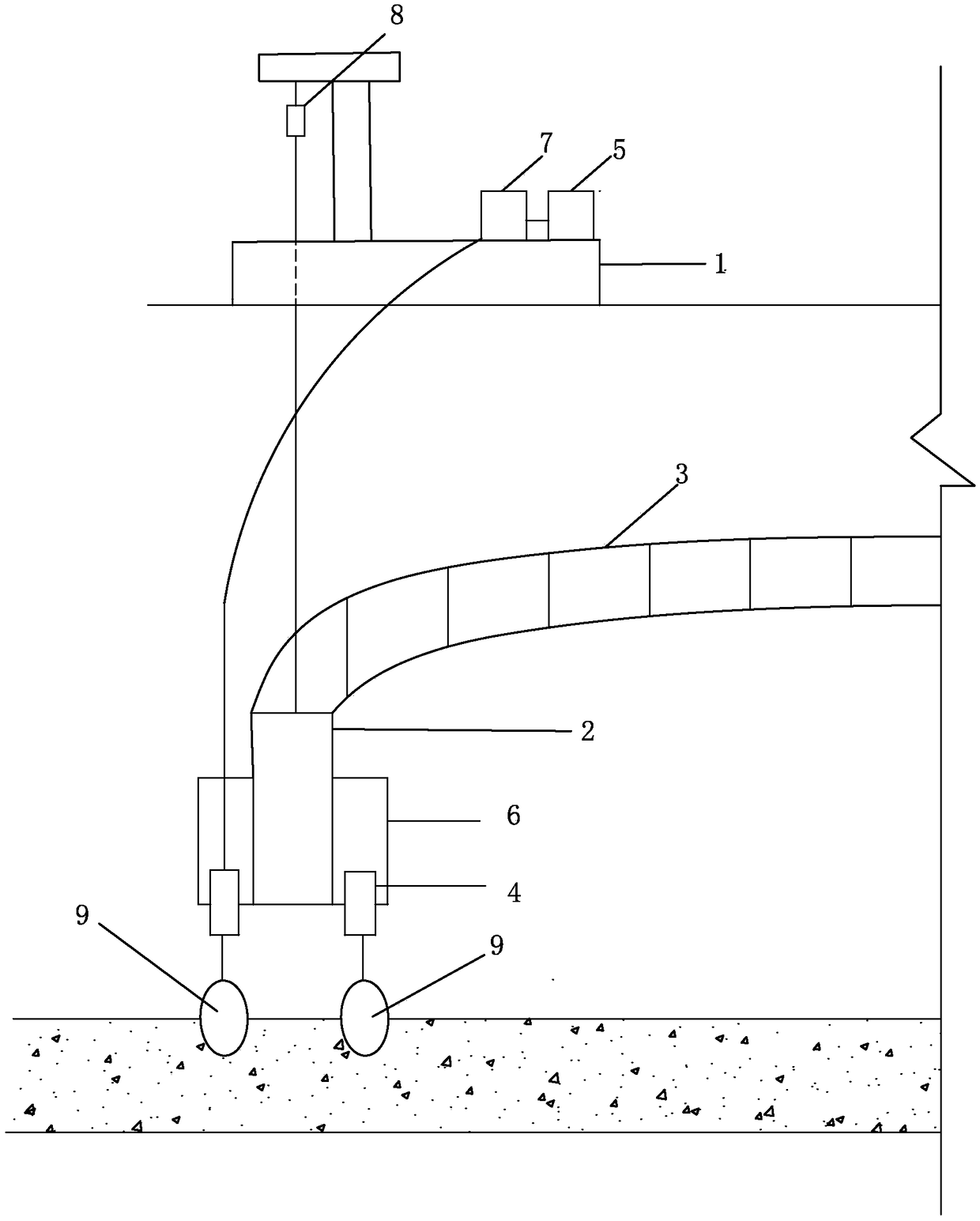

[0030] The following with attached Figure 1 to Figure 3 A reservoir silt suction system and suction method of the present invention will be further described in detail.

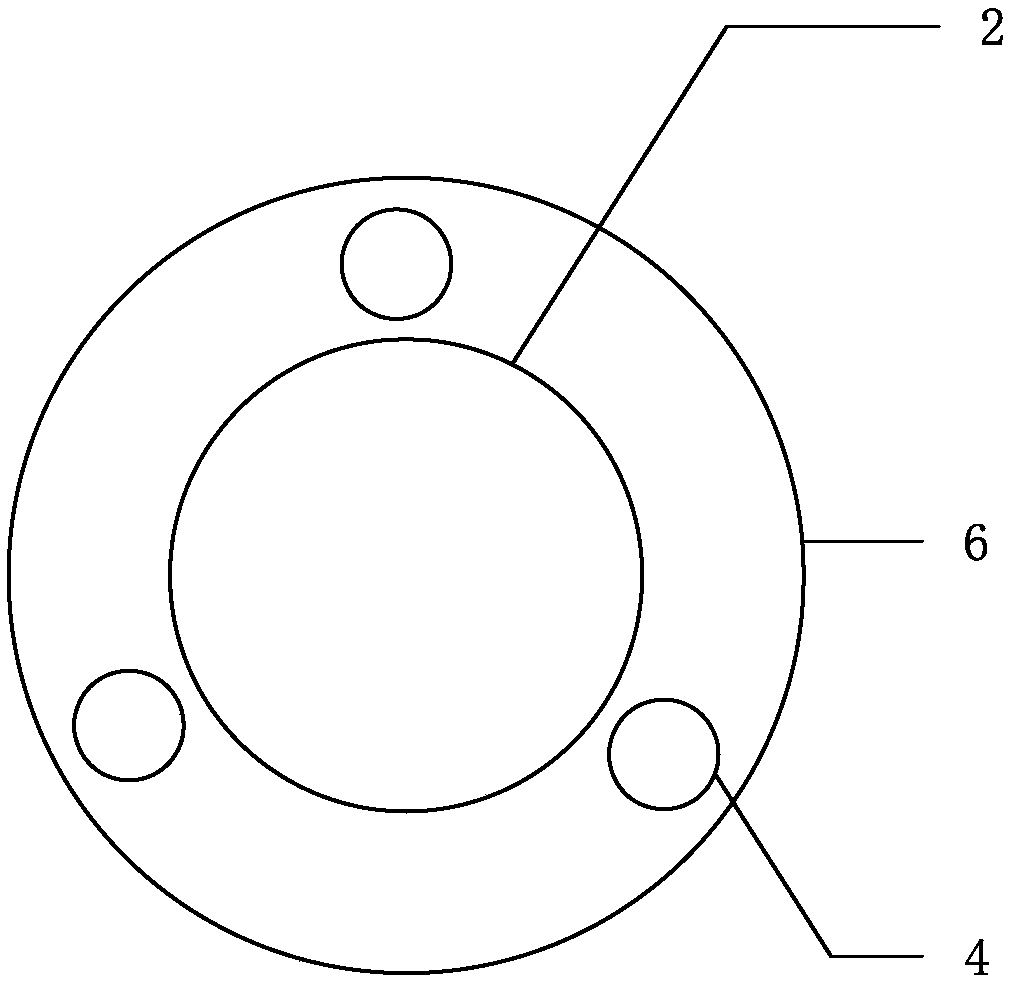

[0031] A kind of reservoir silt suction system of the present invention, please refer to Figure 1 to Figure 3 , including a water work platform 1, a dredging pipe 2, an electric agitator 4, a slurry delivery pipeline 3, a detection sensor assembly, a speed regulating device 5 and a control system, the water work platform 1 is located on the water surface, the detection sensor assembly and The speed regulating devices 5 are all arranged on the above water work platform 1, the described dredging pipe 2 is liftably arranged below the above water work platform 1, and the upper part of the described mud suction pipe 2 is transported to the slurry delivery pipeline 3. The slurry delivery pipeline 3 is connected with the sediment discharge system, the lower part of the electric agitator 4 is in detachable contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com