A kind of preparation method of cotton-polyester double-sided gingham knitted fabric

A technology of knitted fabrics and gingham, applied in the field of textiles, can solve the problems of polyester with hard hand feeling, short service life, poor snag resistance, etc., and achieve soft hand feel, snag resistance up to standard, tear resistance and bursting powerful high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of preparation method of cotton-polyester double-sided gingham knitted fabric, the raw material of this cotton-polyester double-sided gingham knitted fabric comprises compact spinning JC26S / 1 and polyester filament DTY 150D / 144F, comprising the following steps:

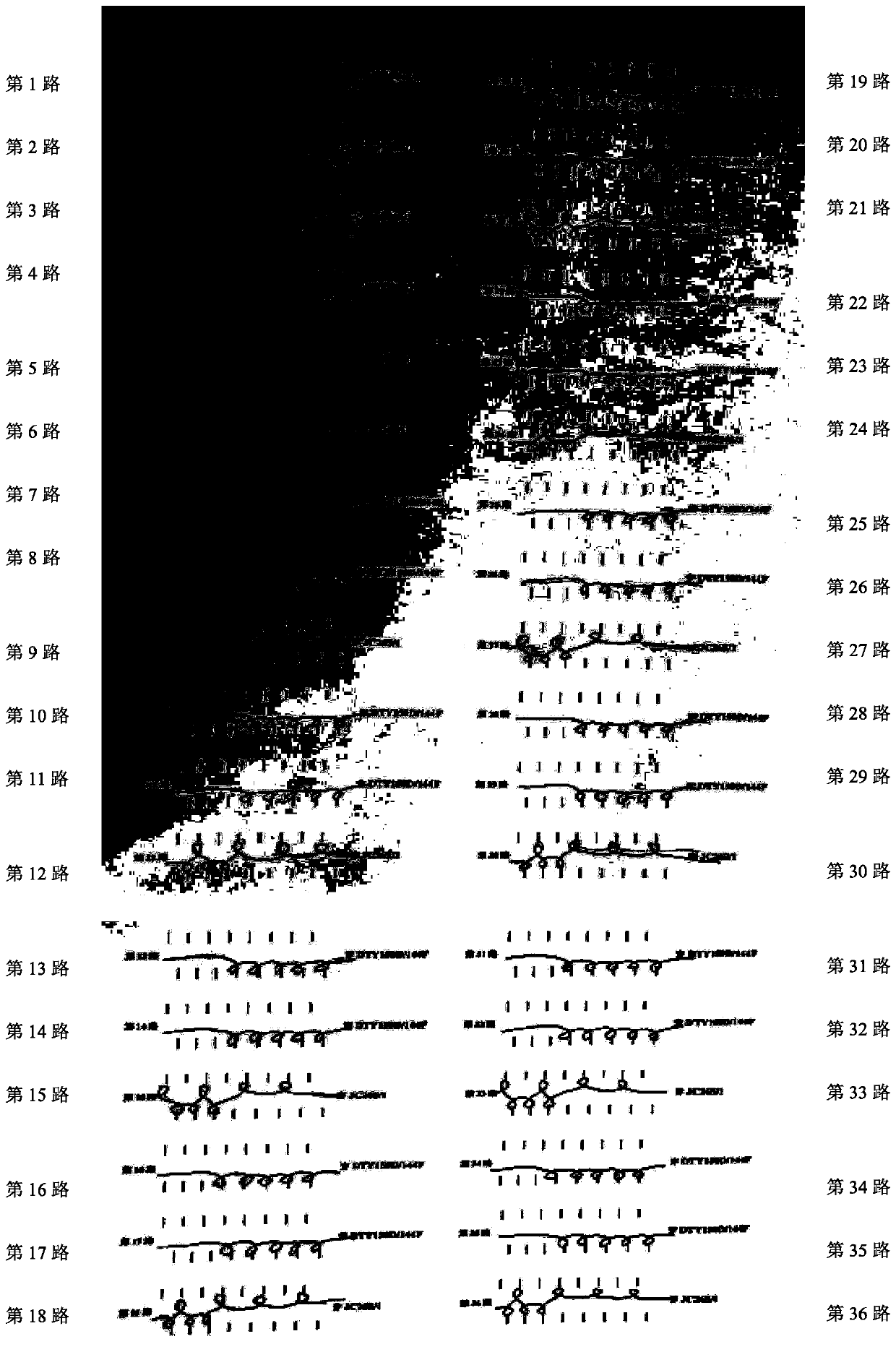

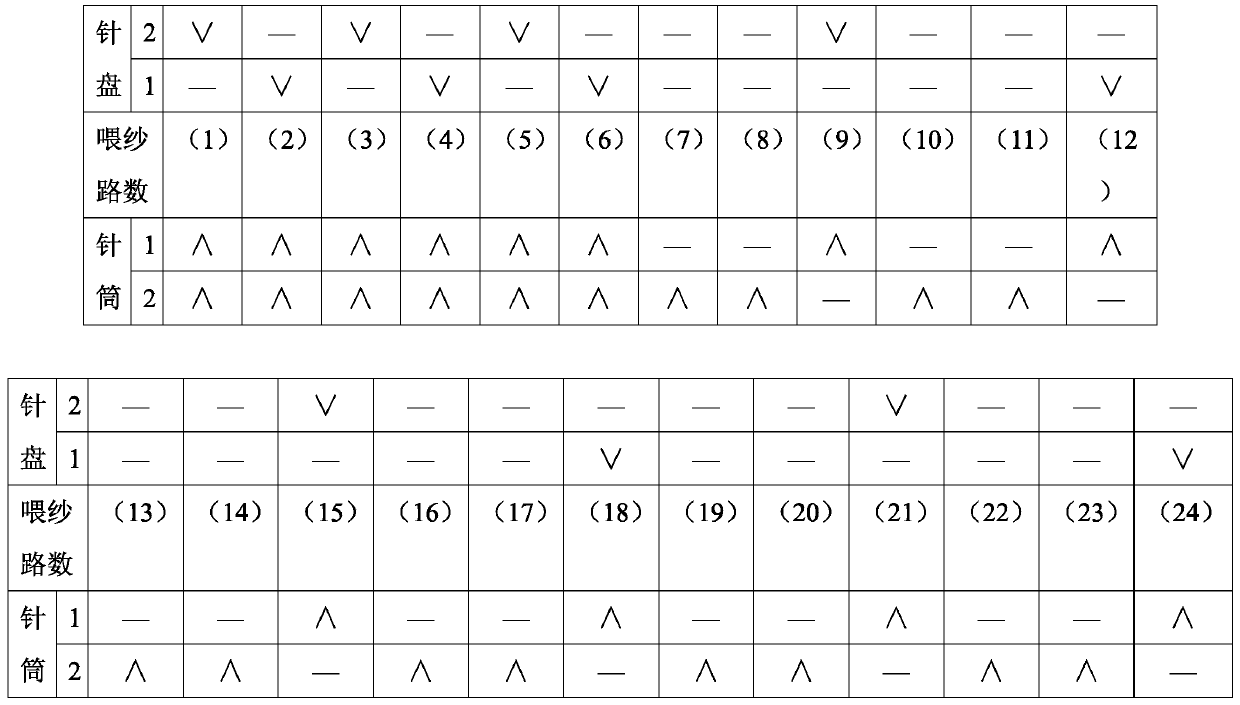

[0038] 1) Weaving: Send the above raw materials into the ordinary double-sided weft knitting large circular machine for weaving to obtain the gray cloth. The dial adopts ABABABAB, and the needle cylinder adopts AAABBBBB needle row. The triangular arrangement of the upper machine is as shown in the table and figure 1 Shown:

[0039]

[0040]

[0041] Among them, ∧ or ∨ means circle, ∩ or ∪ means tuck circle, - means floating line,

[0042] Specific threading method: Number of yarn feeding paths (1)~(6), (9), (12), (15), (18), (21), (24), (27), (30), ( 33) and (36) wear compact spinning JC26S / 1, wherein the thread length of yarn feeding channels (1)~(6) is 49.0cm / 100 needles, and the yarn feeding ch...

Embodiment 2

[0057] A kind of preparation method of cotton-polyester double-sided gingham knitted fabric, the raw material of this cotton-polyester double-sided gingham knitted fabric comprises compact spinning JC26S / 1 and polyester filament DTY 150D / 144F, comprising the following steps:

[0058] 1) Weaving: Send the above raw materials into the ordinary double-sided weft knitting large circular machine for weaving to obtain the gray cloth. The dial adopts ABABABAB, and the needle cylinder adopts AAABBBBB needle row. The triangular arrangement of the upper machine is as shown in the table and figure 1 Shown:

[0059]

[0060]

[0061] Among them, ∧ or ∨ means circle, ∩ or ∪ means tuck circle, - means floating line,

[0062] Specific threading method: Number of yarn feeding paths (1)~(6), (9), (12), (15), (18), (21), (24), (27), (30), ( 33) and (36) wear compact spinning JC26S / 1, wherein the thread length of yarn feeding channels (1) to (6) is 48.5cm / 100 needles, and the yarn feeding...

Embodiment 3

[0078] A kind of preparation method of cotton-polyester double-sided gingham knitted fabric, the raw material of this cotton-polyester double-sided gingham knitted fabric comprises compact spinning JC26S / 1 and polyester filament DTY 150D / 144F, comprising the following steps:

[0079] 1) Weaving: Send the above raw materials into the ordinary double-sided weft knitting large circular machine for weaving to obtain the gray cloth. The dial adopts ABABABAB, and the needle cylinder adopts AAABBBBB needle row. The triangular arrangement of the upper machine is as shown in the table and figure 1 Shown:

[0080]

[0081] Among them, ∧ or ∨ means circle, ∩ or ∪ means tuck circle, - means floating line,

[0082] Specific threading method: Number of yarn feeding paths (1)~(6), (9), (12), (15), (18), (21), (24), (27), (30), ( 33) and (36) wear compact spinning JC26S / 1, wherein the thread length of the yarn feeding paths (1) to (6) is 50.0cm / 100 needles, and the yarn feeding paths (9),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com