Woven or knitted fabrics containing rayon for sheet masks

A technology of knitted fabrics and rayon, which is applied in warp knitting, weft knitting, circular knitting machines with individual moving needles, etc., to achieve good sense of touch, good physical properties, improved coverage and adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0032] Preparation Example 1: Preparation of rayon-containing circular knitted fabric of the present invention

[0033] The method for preparing rayon circular knitted fabrics according to the present invention is a process of warp knitting→knitting (circular knitting)→cleaning→tentering / heat treatment→drying→slitting / cutting→encapsulation. The warp knitting process is a work of warp knitting a package yarn into a weaving and using filaments of the German Enka Company. The knitting process is the work of knitting by a circular knitting machine and knitting (circular knitting) to suit the thickness and basis weight described in this invention. Afterwards, it is cleaned using a cleaner to remove spin finish and foreign matter, then the fabric is heat-treated, dried, cut to size and packed with PE packaging material and finally wrapped in aluminum pouches. Main crafts such as weaving are carried out and provided and used in Gyeongnam Fabric.

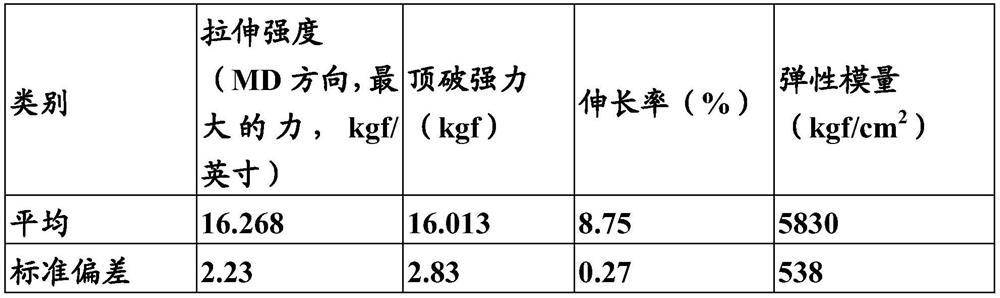

[0034] As for the rayon-containi...

preparation Embodiment 2

[0035] Preparation Example 2: Preparation of rayon-containing warp-knitted fabric of the present invention

[0036] The method of preparing the rayon warp-knitted fabric of the present invention is the same as that of the rayon circular-knitted fabric in Example 1 in that it undergoes warp knitting→knitting→cleaning→tentering / heat treatment→drying→slitting / cutting →Encapsulated process, but the difference is that the weaving process is not circular knitting but warp knitting. The knitting (warp knitting) was performed by a warp knitting machine to suit the thickness and basis weight described in this invention. Afterwards, it is cleaned using a cleaner to remove spin finish and foreign matter, then the fabric is heat-treated, dried, cut to size and packed with PE packaging material and finally wrapped in aluminum pouches. Main crafts such as weaving are carried out and provided and used in Gyeongnam Fabric.

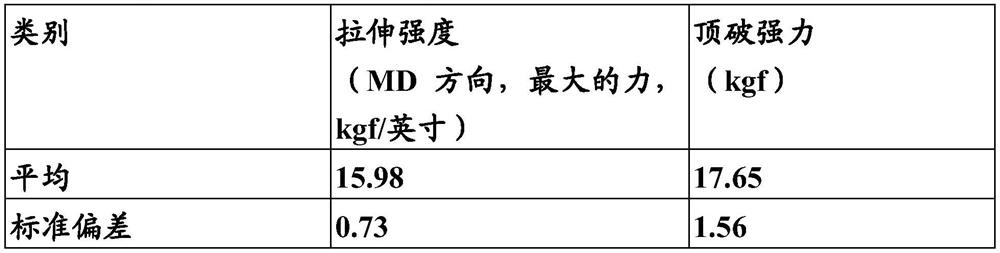

[0037] As for the rayon-containing warp-knitted fabric of the pr...

Embodiment 1

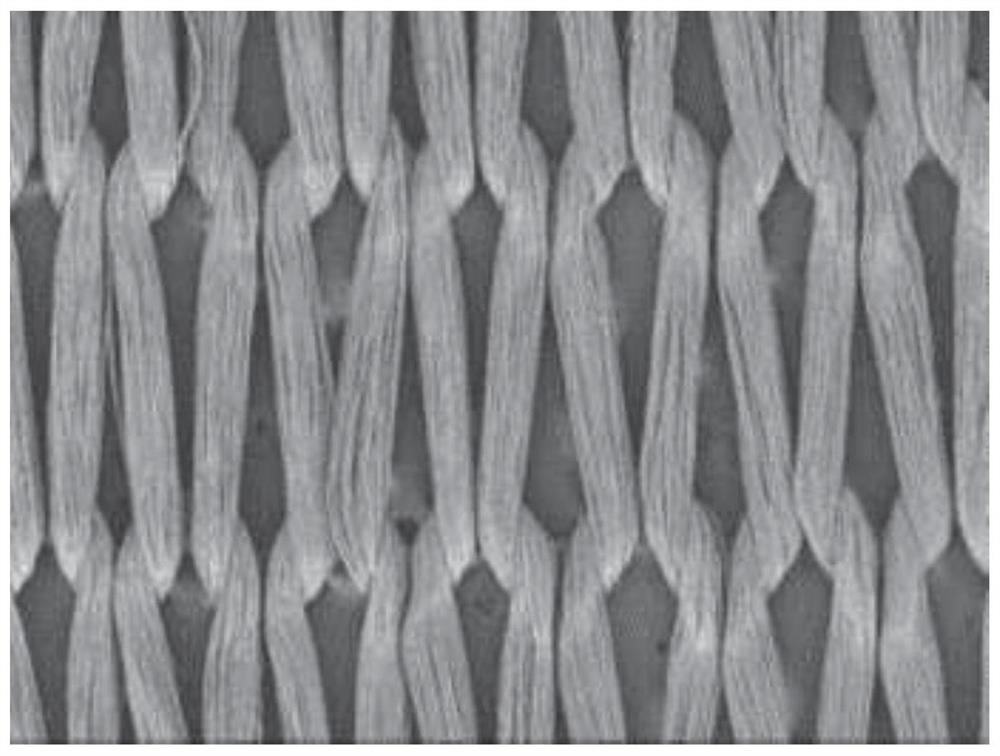

[0038] Example 1: Demonstration of the structure of the rayon-containing knitted fabric of the present invention

[0039] The structure of the rayon-containing circular knitted fabric of the present invention prepared in Production Example 1 was observed using a scanning electron microscope (SEM), and as the scanning electron microscope, a scanning electron microscope (SEM-EDS) manufactured by Jeol (Japan) was used. ) JSM 6335F type, the results are shown below figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| hygroscopicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com