Electrolysis system device and method for electrolyzing copper

An electrolysis system and electrolysis device technology, applied in the chemical field, can solve problems such as the decline in the quality of cathode metal products, low electrolysis efficiency, and increased side reactions of electrolysis hydrogen production, so as to improve electrical efficiency and recover metal quality, improve electrolysis efficiency, and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

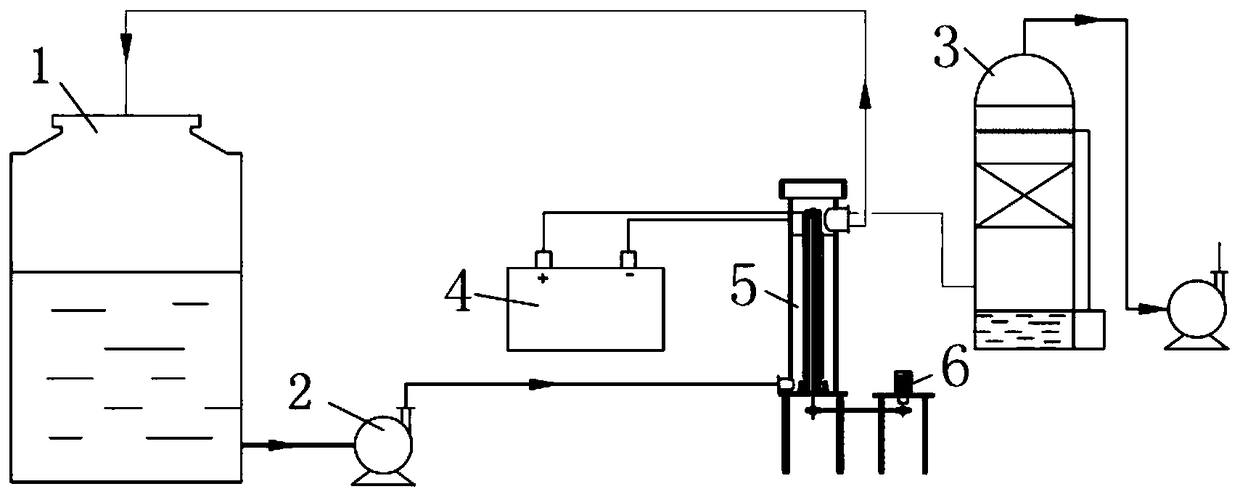

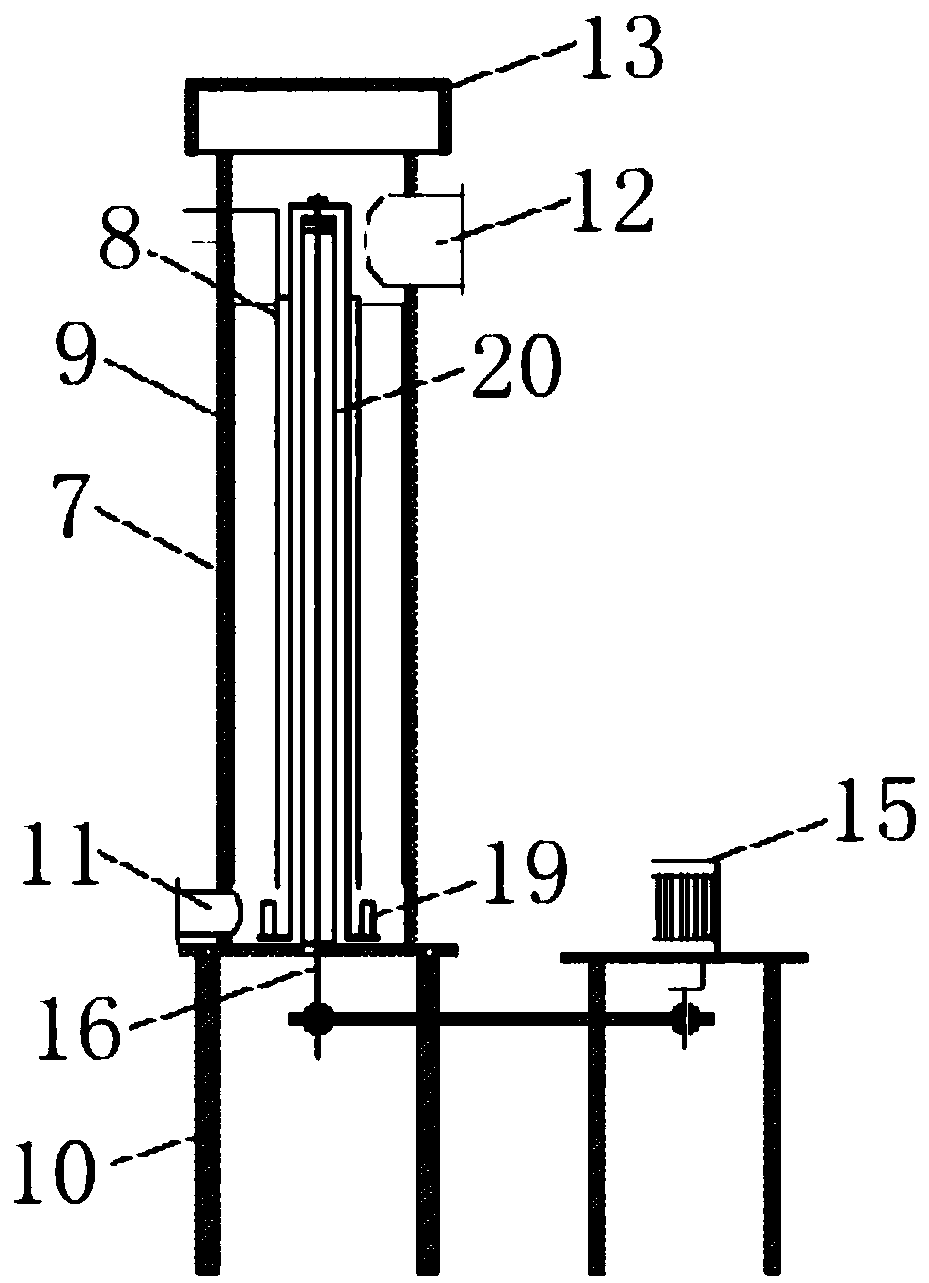

[0041] The present embodiment combines the copper ion solution that ion concentration is 40g / L as an example, a kind of electrolysis system device provided by the present invention, such as figure 1 As shown, it includes a solution storage 1, a circulation mechanism 2, an electrolysis mechanism and a recovery mechanism 3, and the solution storage 1, circulation mechanism 2, electrolysis mechanism and recovery mechanism 3 are connected in sequence, and the electrolysis mechanism includes a power supply device 4, an electrolysis device 5 and a stirring device 6. The electrolysis device 5 is connected to the solution storage 1 . During electrolysis, the copper-containing solution is first added to hydrogen peroxide for pretreatment and then poured into the solution storage 1, the copper solution is pumped into the electrolysis device 5 by the circulation mechanism 2, the power supply device 4 and the stirring device 6 are turned on, and the stirring device 6 is stirred , the copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com