Method and application for synthesizing cheap nickel-iron nanosheet array high-efficiency electrocatalyst at normal temperature and normal pressure

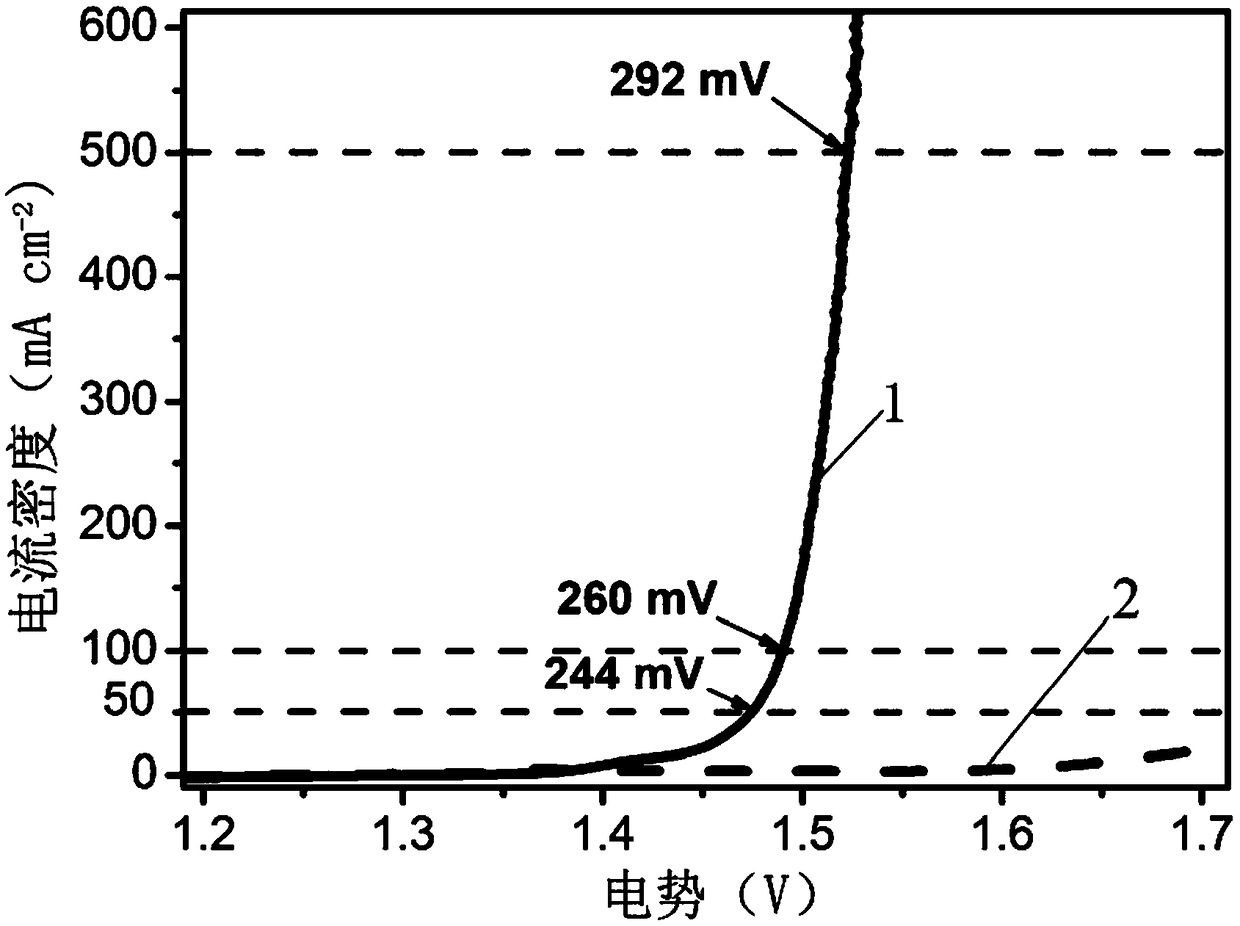

A nanosheet array and electrocatalyst technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of harsh synthesis conditions, restrictions on large-scale production and application, and poor stability of nickel-iron catalysts for large-scale application, and achieve green and reliable Sustained hydrogen energy production, increased electron transfer rate, and improved catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

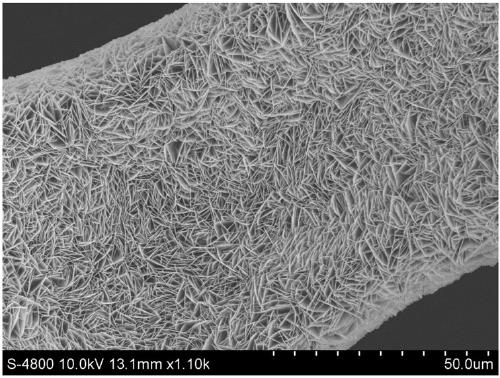

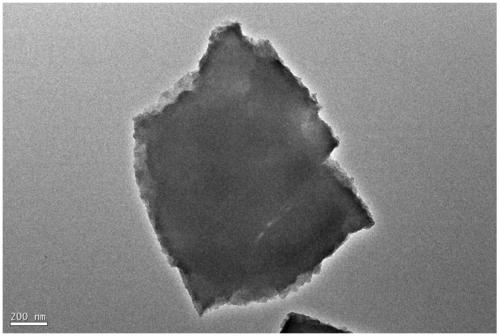

[0040] Embodiment 1: This embodiment is a method for synthesizing cheap nickel-iron nanosheet array high-efficiency electrocatalysts under normal temperature and pressure, which is completed according to the following steps:

[0041] 1. Pretreatment of nickel foam:

[0042] Immerse commercial nickel foam in dilute hydrochloric acid with a concentration of 2mol / L-4mol / L for 5min-10min, and after taking it out, first rinse it with absolute ethanol for 3-5 times, and then rinse it with distilled water for 3-5 times to obtain Nickel foam to remove impurities;

[0043] 2. Preparation of iron solution:

[0044] Dissolve the iron salt in deionized water, and then perform ultrasonication for 5-10 minutes to obtain an iron salt solution;

[0045]The concentration of the iron salt solution described in step 2 is 100mmol / L~300mmol / L;

[0046] 3. Soaking:

[0047] The foamed nickel from which impurities have been removed is soaked in the iron salt solution for 1 h to 10 h at room temp...

specific Embodiment approach 2

[0056] Embodiment 2: This embodiment differs from Embodiment 1 in that: the thickness of the commercialized nickel foam described in step 1 is 0.5 mm to 1 mm, and the pore diameter is 1 μm to 100 μm. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0057] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the iron salt described in step 2 is ferric nitrate nonahydrate. Other steps are the same as those in Embodiment 1 or 2.

[0058] In this embodiment, ferric nitrate nonahydrate is analytically pure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com