Method for improving straw high-solid anaerobic digestion to produce methane

A technology of anaerobic digestion and methane production, which is applied in the direction of waste fuel, fermentation, etc., can solve the problems of low spraying efficiency and long time, achieve good treatment effect, reduce water content, and optimize process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a method for improving methane production by high-solid anaerobic digestion of straw, wherein the method includes:

[0044] Raw material: corn stalks;

[0045] Production steps:

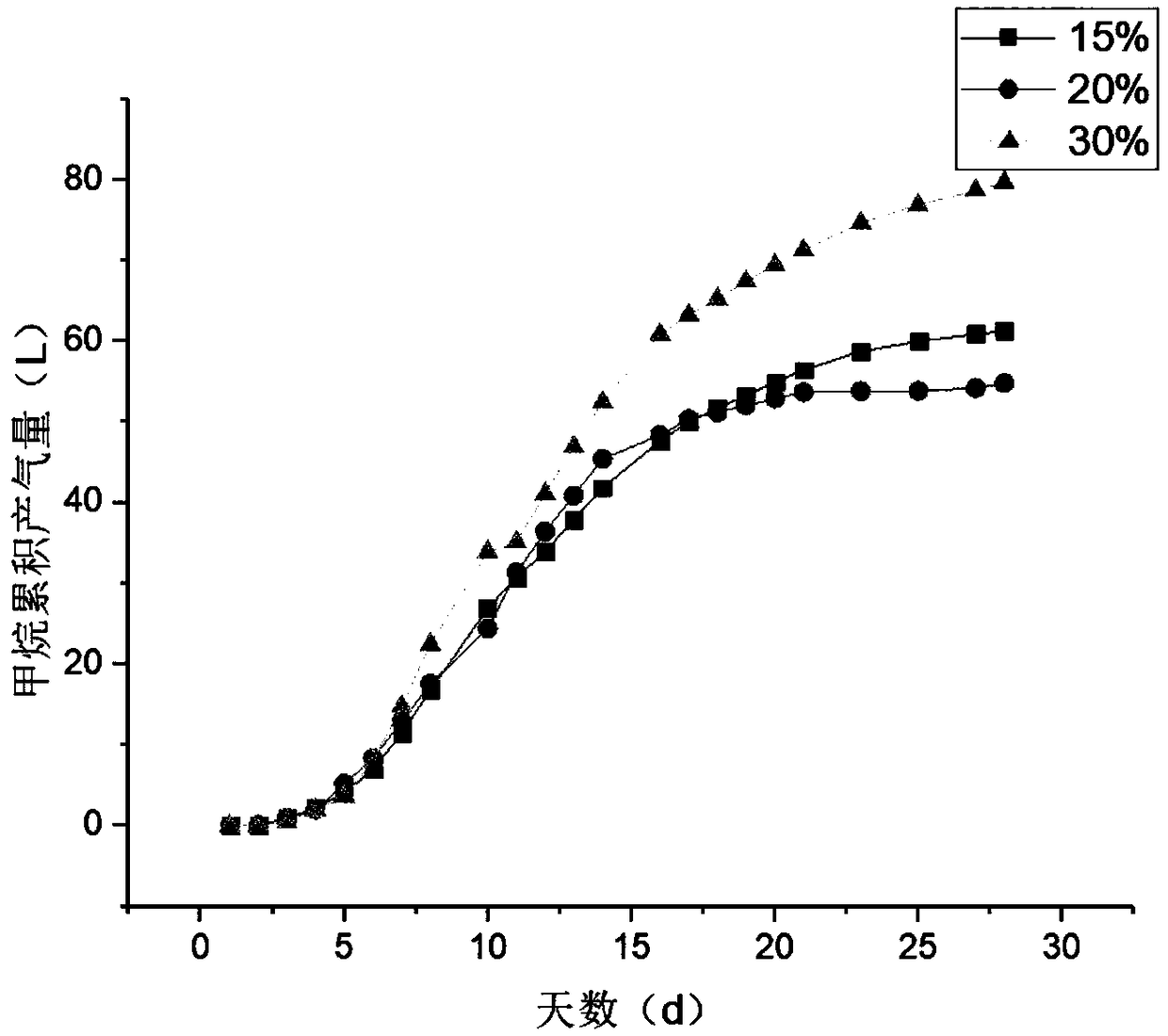

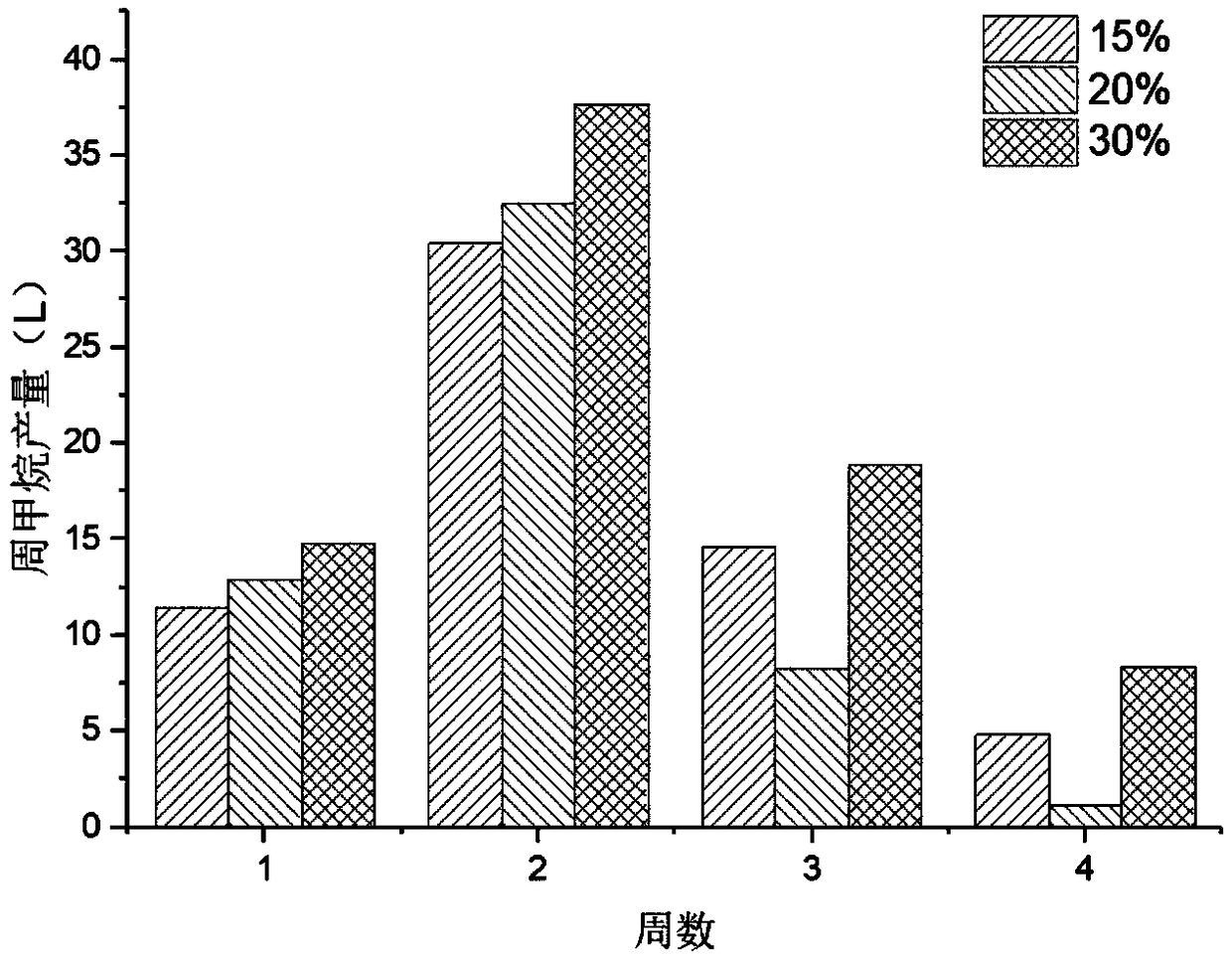

[0046] (1) Adjust the silage corn stalks with a particle size of 2-3cm to 15%, 20%, and 30% of their solid content with mixed distilled water, and the inoculum is the domesticated biogas slurry taken out of a 37°C constant temperature incubator in advance , Soak the raw materials with the inoculum for 2 hours before the start of the experiment.

[0047] (2) Add the mixture obtained in step (1) to the dry fermentation chamber of the garage-type anaerobic reactor, and spray back from the top. Minutes, no spraying in the fourth week, and the spraying interval is 3 hours. The reaction time for the anaerobic digestion of the mixed raw material in the reactor to produce methane is 28 days. The reaction temperature was 37±1°C, and the pH was not adjusted.

[0048] In the...

Embodiment 2

[0050] This embodiment provides a method for improving methane production by high-solid anaerobic digestion of straw, wherein the method includes:

[0051] Raw material: corn stalks;

[0052] Production steps:

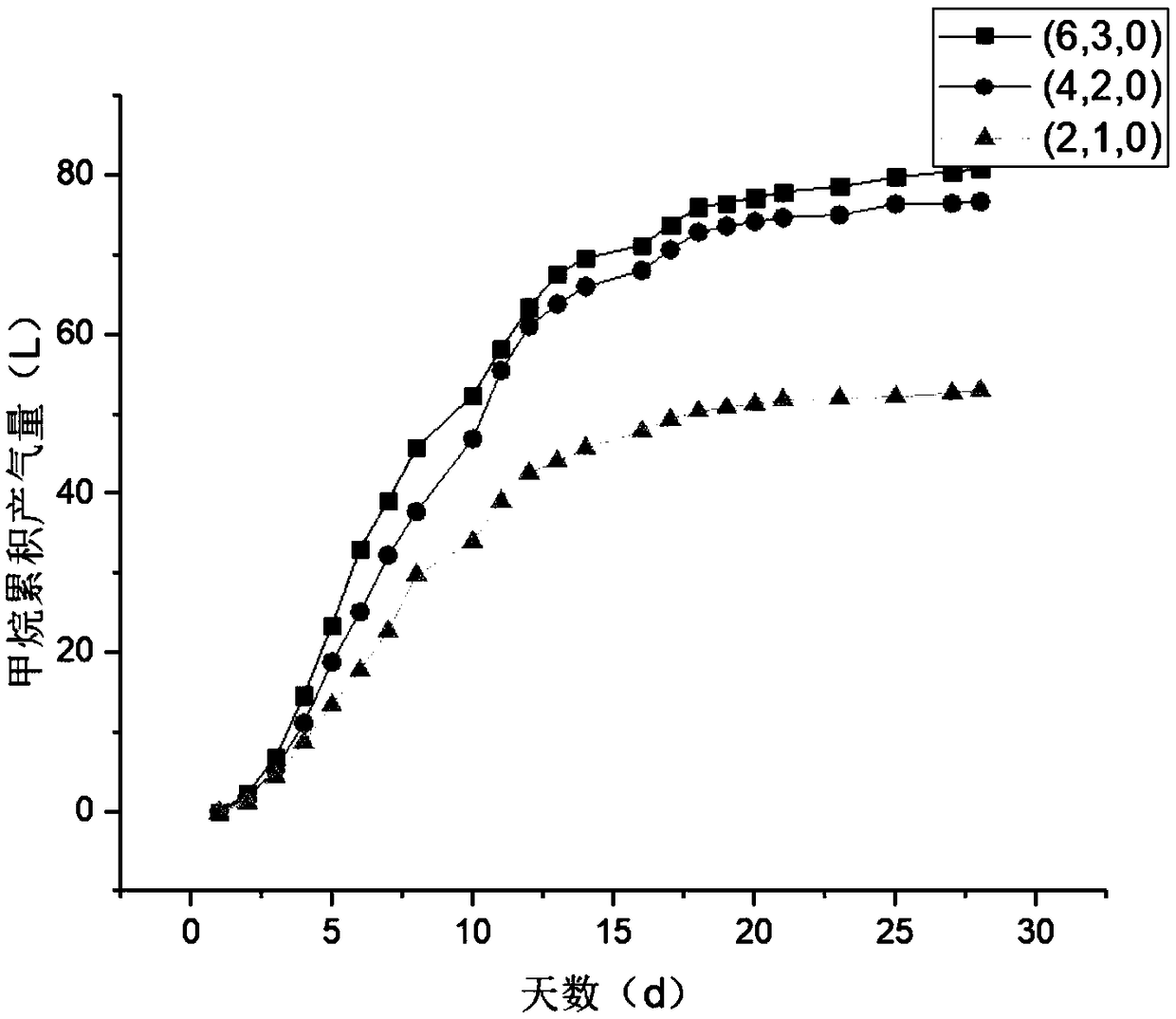

[0053] (1) Use mixed distilled water to adjust the solid content of silage corn stalks with a particle size of 2-3cm to 30%. The raw materials were soaked in liquid for 2h.

[0054] (2) Add the mixture obtained in step (1) to the dry fermentation chamber of the garage-type anaerobic reactor, and spray back from the top. 3 minutes every week, no spraying in the fourth week (expressed as (6, 3, 0));

[0055] Method 2: 4 minutes each time in the first two weeks, 2 minutes each time in the third week, no spraying in the fourth week (expressed as (4, 2, 0));

[0056] Method 3: 2 minutes each time in the first two weeks, 1 minute each time in the third week, no spraying in the fourth week (expressed as (2, 1, 0)). The spraying time interval is 3 hours. The reaction tim...

Embodiment 3

[0059] This embodiment provides a method for improving methane production by high-solid anaerobic digestion of straw, wherein the method includes:

[0060] Raw material: corn stalks;

[0061] Production steps:

[0062] (1) Use mixed distilled water to adjust the solid content of silage corn stalks with a particle size of 2-3cm to 30%. The raw materials were soaked in liquid for 2h.

[0063] (2) Add the mixture obtained in step (1) to the dry fermentation chamber of the garage-type anaerobic reactor, and spray back from the top. Minutes, the fourth week without spraying. The spray intervals were 3 hours, 6 hours, and 8 hours. The reaction time for the anaerobic digestion of the mixed raw materials in the reactor to generate methane is 28 days. The reaction temperature was 37±1°C, and the pH was not adjusted.

[0064] During the 28 days that the reaction was carried out, the volume of gas produced was measured at regular intervals, and the relationship between methane prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com