Autoclaved ceramic powder aerated concrete self-insulating block

A technology of air-entrained concrete and self-insulating blocks, which is applied in ceramic products, applications, household appliances, etc., can solve the problems of poor frost resistance, cracking and peeling, and rapid thickening of slurry, so as to improve strength and frost resistance. performance, the inner surface is dense and smooth, and the effect of stable pouring is guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

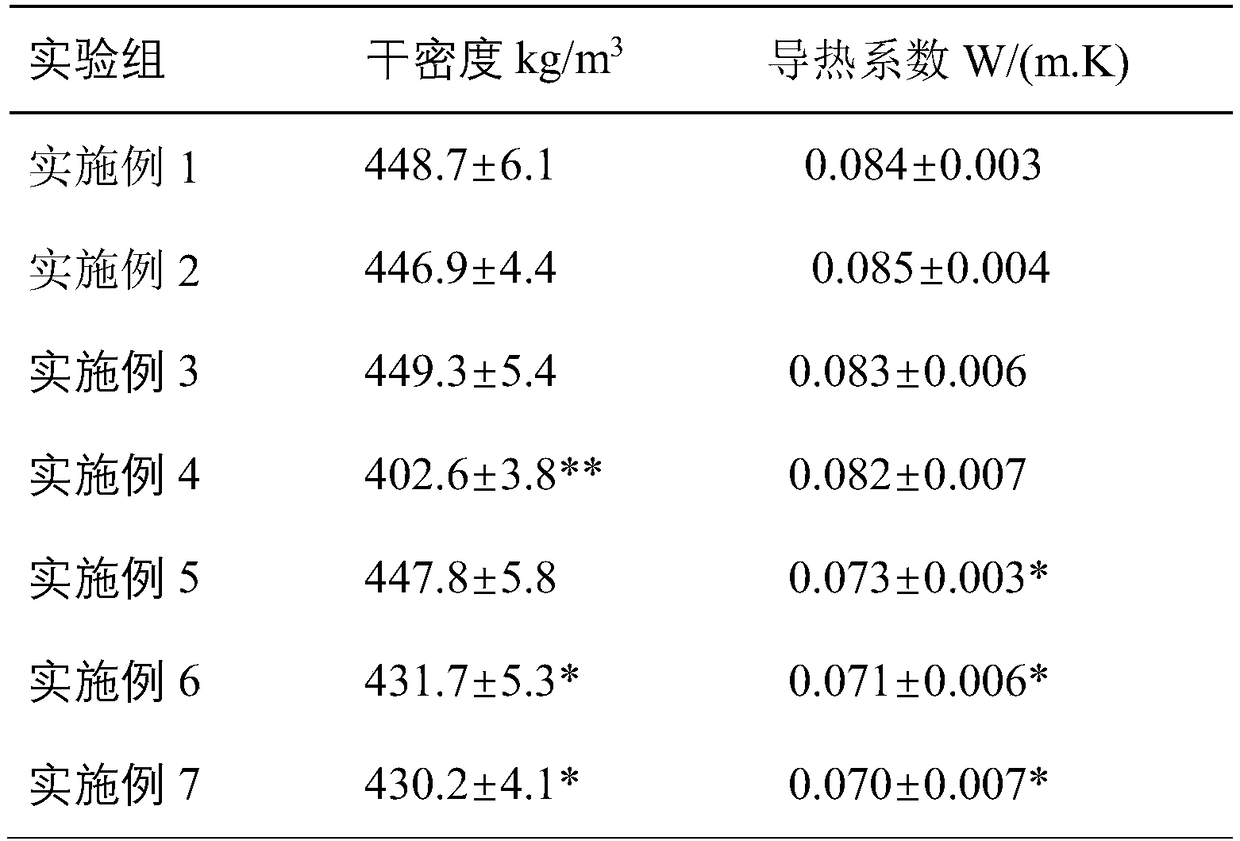

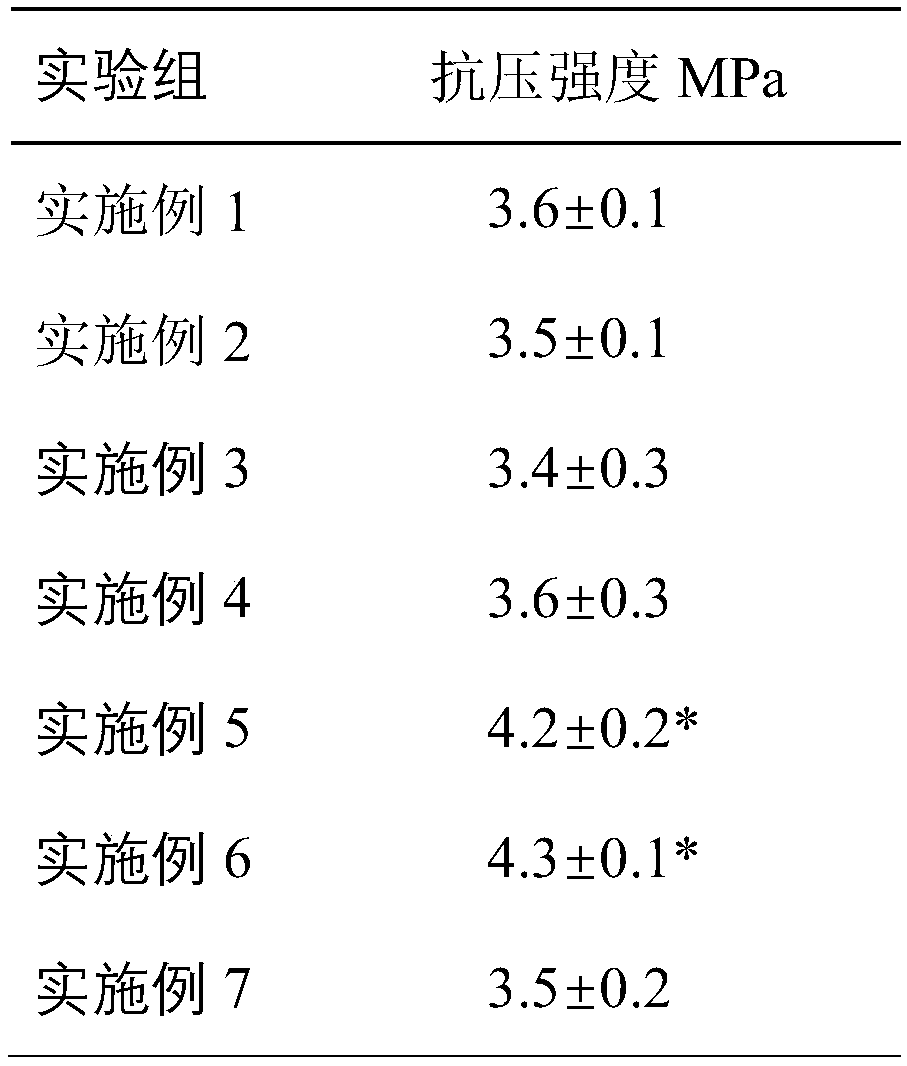

Examples

Embodiment 1

[0032] An autoclaved porcelain powder aerated concrete self-insulating block, made of the following raw materials in parts by weight: 55 parts of ceramic waste slag powder, 12 parts of quicklime, 8 parts of cement, 4 parts of gypsum, 3 parts of aluminum powder, and ferrosilicon powder 4 parts, 20 parts of waste slurry, 0.1 part of rosin, 0.1 part of sodium fatty alcohol sulfonate, 0.2 part of wood calcium, 0.05 part of sodium hexametaphosphate, and 80 parts of water.

[0033] The preparation method of the above-mentioned autoclaved porcelain powder aerated concrete self-insulating block is carried out according to the following steps:

[0034] (1) Take by weight 55 parts of ceramic waste slag powder as a siliceous raw material; 12 parts of quicklime as a calcareous raw material; 8 parts of cement as a body reinforcing agent; 4 parts of gypsum as a regulator; aluminum powder 3 parts, 4 parts of ferrosilicon powder, are gas-generating agent as mixture; Mix above-mentioned materi...

Embodiment 2

[0039] An autoclaved porcelain powder aerated concrete self-insulating block, made of the following raw materials in parts by weight: 45 parts of ceramic waste slag powder, 10 parts of quicklime, 6 parts of cement, 3 parts of gypsum, 2 parts of aluminum powder, and ferrosilicon powder 3 parts, 15 parts of waste slurry, 0.1 part of resin, 0.1 part of sodium alkylbenzene sulfonate, 0.1 part of white sugar, 0.03 part of water glass, and 50 parts of water.

[0040] The preparation method of the above-mentioned autoclaved porcelain powder aerated concrete self-insulating block is carried out according to the following steps:

[0041] (1) Take by weight 45 parts of ceramic waste slag powder as a siliceous raw material; 10 parts of quicklime as a calcareous raw material; 6 parts of cement as a green body reinforcing agent; 3 parts of gypsum as a regulator; aluminum powder 2 parts, 3 parts of ferrosilicon powder, as a mixture is an air-generating agent; mix the above-mentioned materia...

Embodiment 3

[0046] An autoclaved porcelain powder aerated concrete self-insulating block, made of the following raw materials in parts by weight: 66 parts of ceramic waste slag powder, 15 parts of quicklime, 10 parts of cement, 5 parts of gypsum, 5 parts of aluminum powder, and ferrosilicon powder 6 parts, 25 parts of waste slurry, 0.3 part of wood calcium, 0.25 part of sodium alkylbenzene sulfonate, 0.1 part of borax, and 120 parts of water.

[0047] The preparation method of the above-mentioned autoclaved porcelain powder aerated concrete self-insulating block is carried out according to the following steps:

[0048] (1) Take by weight 66 parts of ceramic waste slag powder as a siliceous raw material; 15 parts of quicklime as a calcareous raw material; 10 parts of cement as a green body reinforcing agent; 5 parts of gypsum as a regulator; aluminum powder 5 parts, 6 parts of ferrosilicon powder, are gas-generating agent as mixture; Mix above-mentioned material, make mixed material A;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com