Novel micro-electrolysis unit for treating oily wastewater

A new type of micro-electrolysis technology, applied in special treatment targets, water/sewage treatment, water/sewage treatment equipment, etc., can solve the problems of micro-electrolysis packing compaction, passivation cleaning and replacement, inconvenience, etc., to achieve uniform water distribution, The effect of long service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Adjust the pH value of the test wastewater with an oil concentration of 30mg / L to 3.0, take 200mL of the wastewater with this concentration, and add the prepared filler to the reaction zone of the micro-electrolysis device at a ratio of 1:5200g / L to treat the oily wastewater At the same time, the auxiliary aeration is strengthened. During the reaction process, samples are taken at intervals of 10 minutes. The micro-electrolysis reaction time is set to 60 minutes. The oil removal effect shows a rapid increase trend with the increase of fillers. The maximum removal rate can reach 81.4%, and the pH value of the effluent is 4-5, reaching the water discharge standard. After several days of continuous operation, the filler has no hardening, passivation, waste residue, etc.

Embodiment 2

[0079] Adjust the pH value of the test wastewater with an oil concentration of 100mg / L to 3.0, take 200mL of the wastewater of this concentration, and add the prepared filler to the reaction zone of the micro-electrolysis device at a ratio of 1:4250g / L to treat the oily wastewater At the same time, the auxiliary aeration is strengthened. During the reaction process, samples are taken at intervals of 10 minutes. The micro-electrolysis reaction time is set to 60 minutes. The oil removal effect shows a rapid increase trend with the increase of the filler. The removal rate can reach 79.8%, and the pH of the effluent is 4-5, reaching the water discharge standard. After several days of continuous operation, the filler has no hardening, passivation, waste residue, etc.

Embodiment 3

[0081] Adjust the pH value of the test wastewater with an oil concentration of 200mg / L to 3.0, take 200mL of the wastewater with this concentration, and add the prepared filler to the reaction zone of the micro-electrolysis device at a ratio of 1:2500g / L to treat the oily wastewater At the same time, the auxiliary aeration is strengthened. During the reaction process, samples are taken at intervals of 10 minutes. The micro-electrolysis reaction time is set to 60 minutes. The oil removal effect shows a rapid increase trend with the increase of fillers. 4-5, reaching the water discharge standard. After several days of continuous operation, the filler has no hardening, passivation, waste residue, etc.

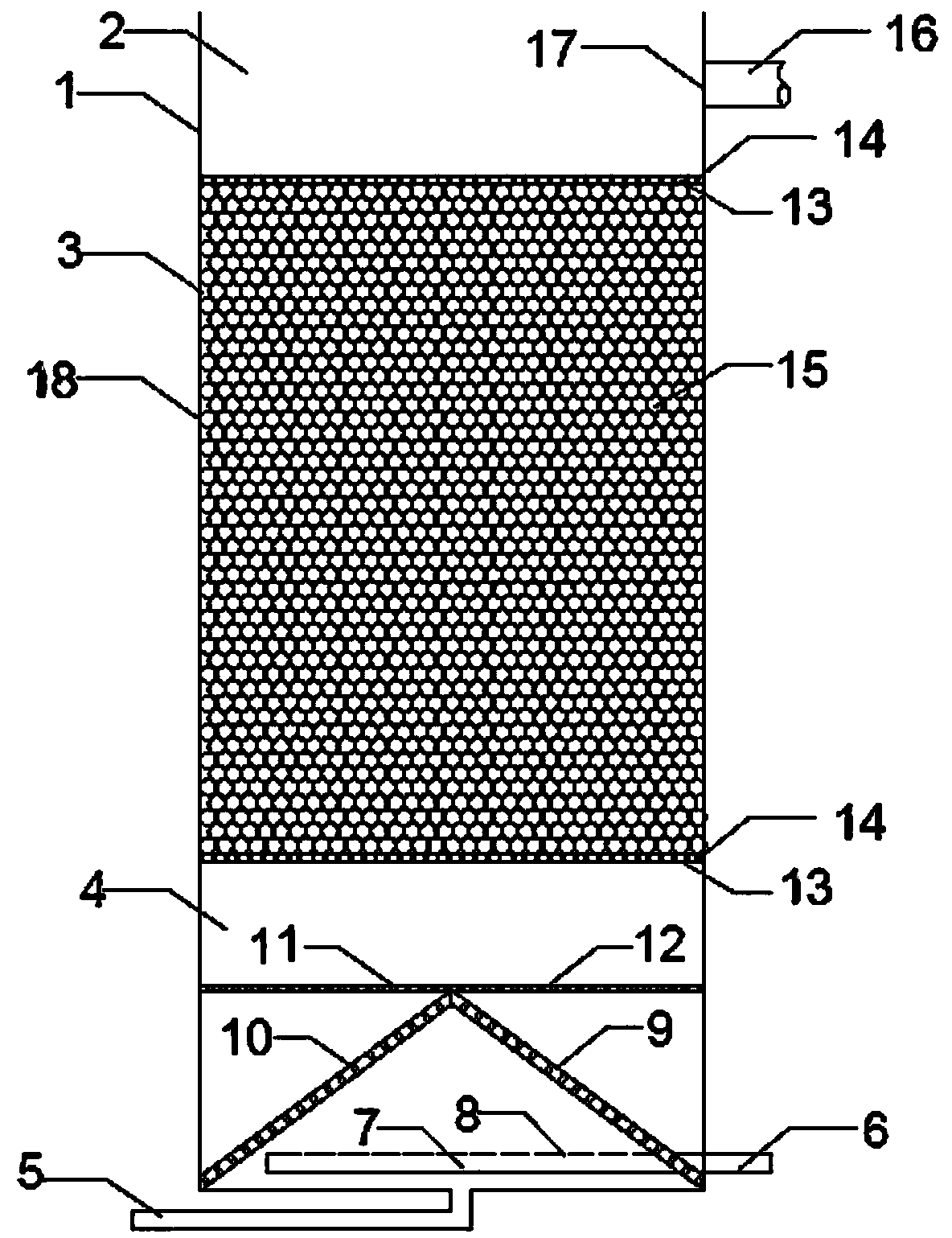

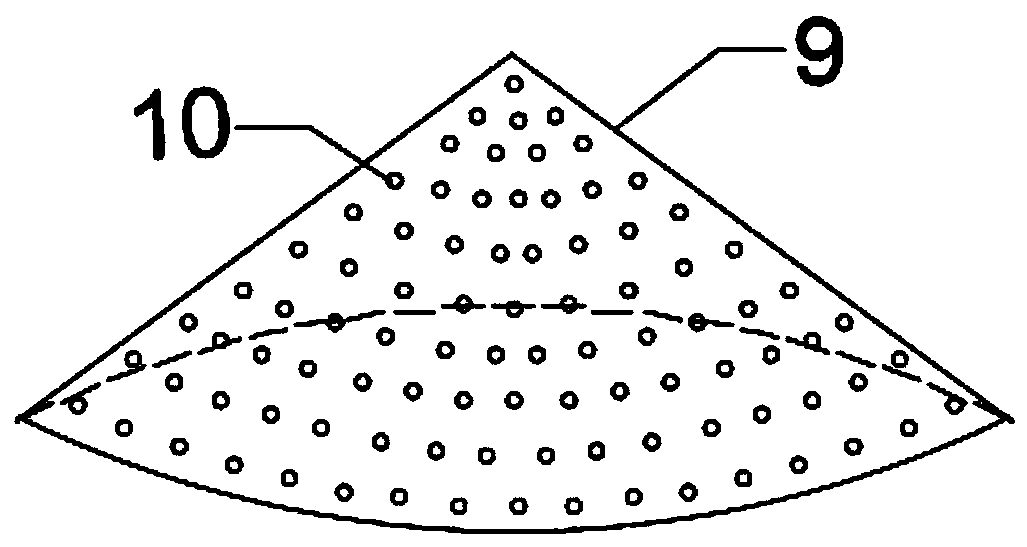

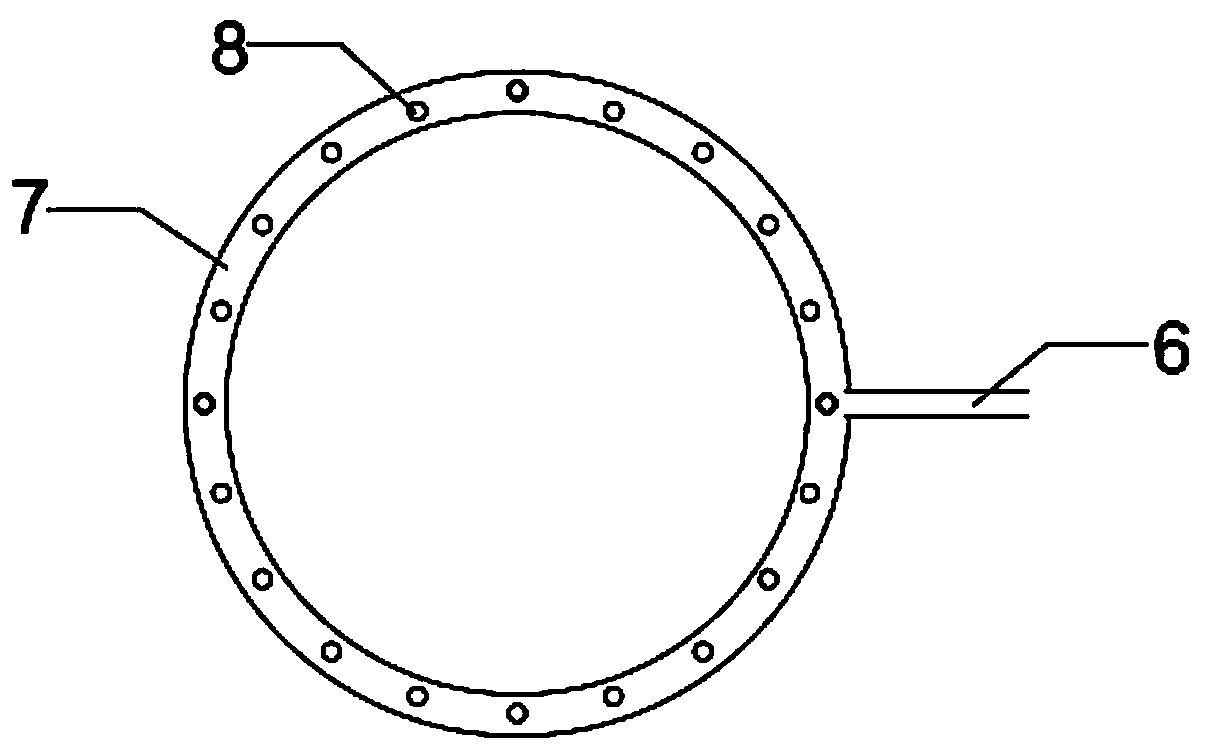

[0082] To sum up: the present invention discloses a novel micro-electrolysis device for treating oily waste water, which includes a cylinder, which is divided into a water collection area, a reaction area, and a water inlet area from top to bottom. The upper part of the water col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com