Method for lifting and releasing descending mechanism through intelligent winch device

A hoisting device, intelligent technology, applied in the direction of hoisting device, clockwork mechanism, fluid pressure actuating device, etc., can solve the problem that the movement cannot be guaranteed at one time, the lifting and lowering mechanism cannot move, and the buffer friction braking cannot be realized and other problems, to achieve the effect of improving the deceleration and braking effect, improving the working reliability and service life, and the effect of large braking torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

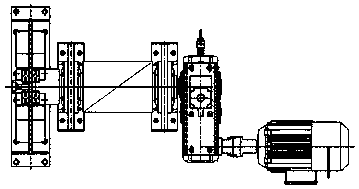

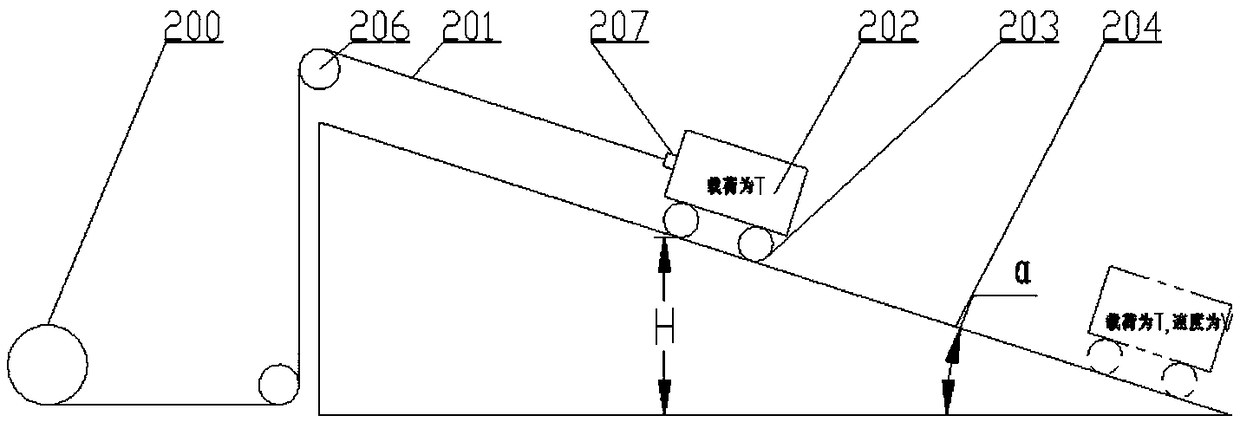

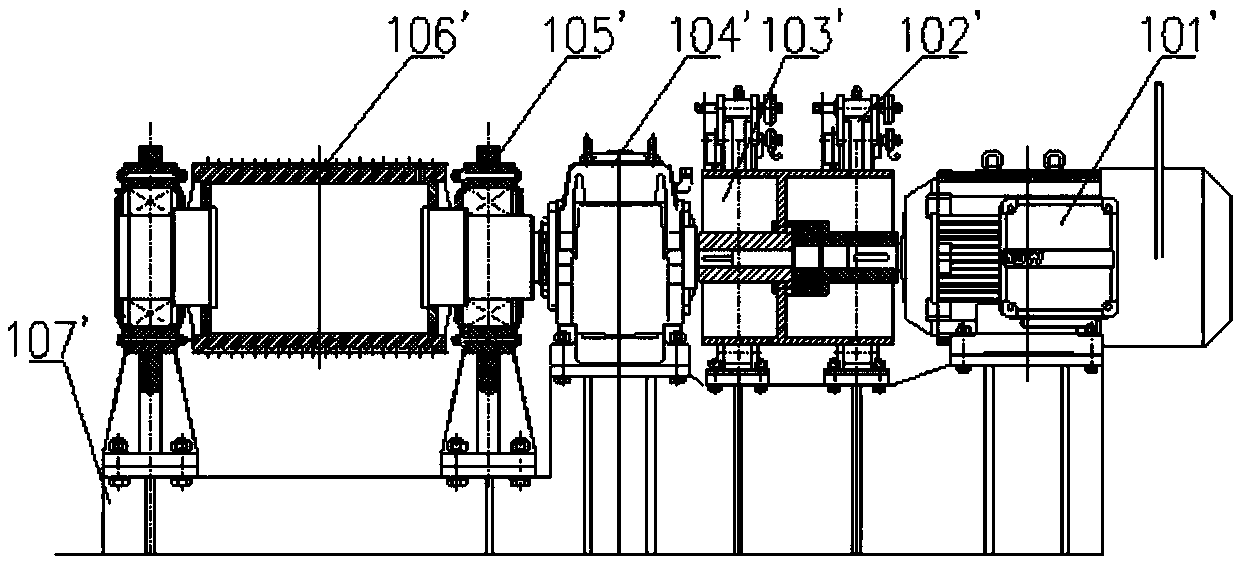

[0053] The present invention provides a method for lifting and releasing a lowering mechanism through an intelligent hoisting device, including:

[0054] By setting the information acquisition element on the output shaft of the drum of the intelligent hoisting device, the moving speed and position information of the load vehicle lifted by the wire rope on the drum can be obtained;

[0055] By setting the caliper disc brake on the output shaft of the reel, it provides braking force for the moving load vehicle;

[0056] Provide hydraulic oil for the caliper disc brake by connecting multiple hydraulic oil ports of the caliper disc brake to the hydraulic system with electromagnetic overflow valve, proportional pressure reducing valve and electromagnetic reversing valve respectively;

[0057] By connecting the hydraulic system, information acquisition components and the control system separately, the control system controls one or more of the electromagnetic overflow valve, proport...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com