Brake pedal assembly with steering angle sensor

A technology of rotation angle sensor and brake pedal, which is applied in the direction of brake safety system, foot start device, etc., to achieve the effect of improving the accuracy of assembly positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

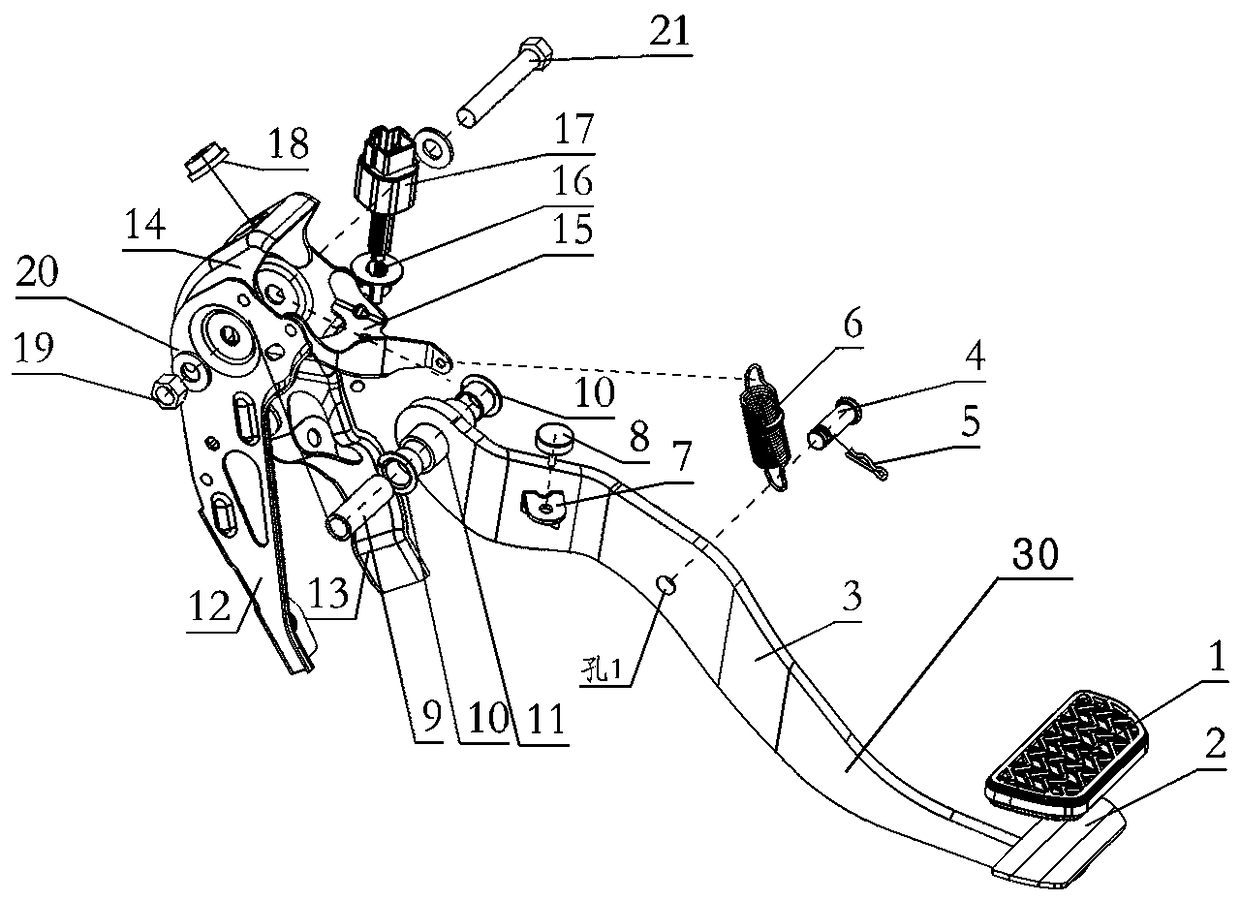

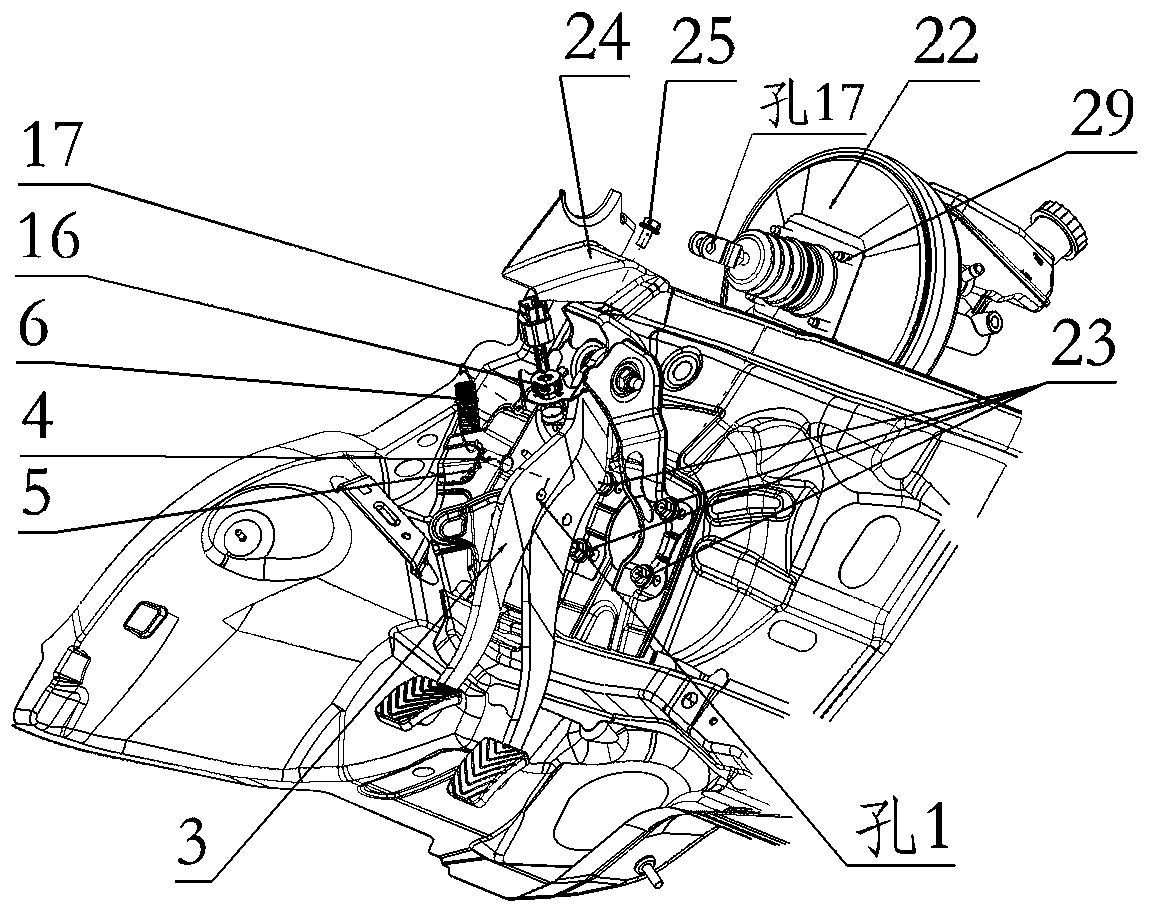

[0026] Embodiment 1: switch bracket 15 brake light switch installation buckle 16 pin shaft 4β pin 5 return spring 6 is assembled together with the brake pedal main body 30 in the assembly workshop, the present invention is based on the brake pedal main body 30 Additional design, switch bracket 15 brake light switch installation buckle 16 pin shaft 4, β pin 5 return spring 6 is not included in the present invention, but according to the design state, it also needs to be assembled in the assembly workshop to realize the basic function of the brake pedal Features.

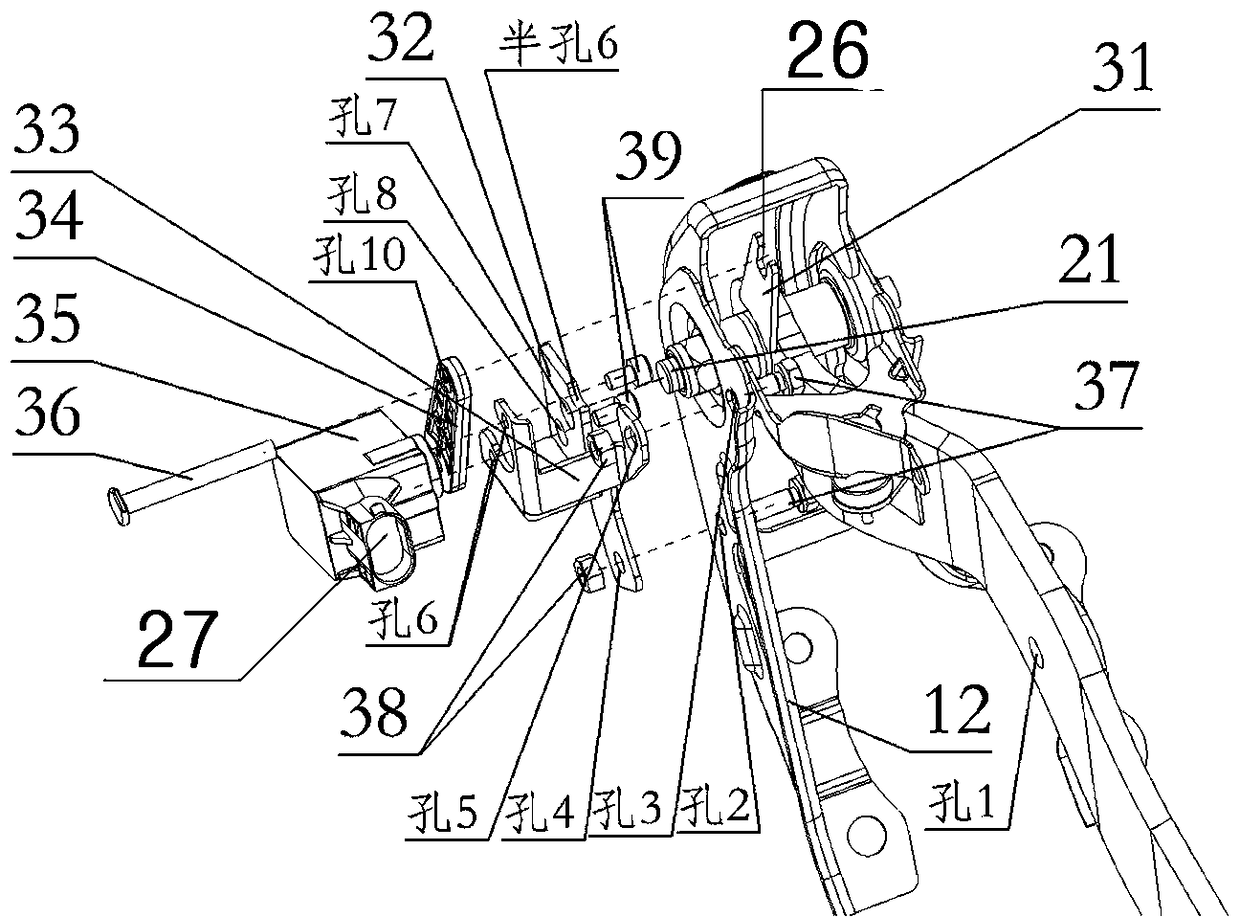

[0027] Shift fork 31 is welded on the pedal arm 3, and rotates together with it. Sensor bracket I and sensor bracket II are welded together. The sensor-pipe shaft 36 is press-fitted in the hole 10 of the rocker arm 34, and the sensor-pipe shaft 36 cooperates with the opening groove 11 of the shift fork 31. The front end of the stud (M5) 39 passes through the hole 9 of the sensor bracket II to cooperate with the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com