Printing table, printing apparatus and printing method for inkjet printing

A technology of inkjet printing and printing equipment, applied in printing, typewriter and other directions, can solve the problem of sub-regional control of the fluidity of printing materials that cannot be realized, and achieve the effect of improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the technical problems, technical solutions and advantages to be solved by the present invention more clear, the following will be described in detail with reference to the accompanying drawings and specific embodiments.

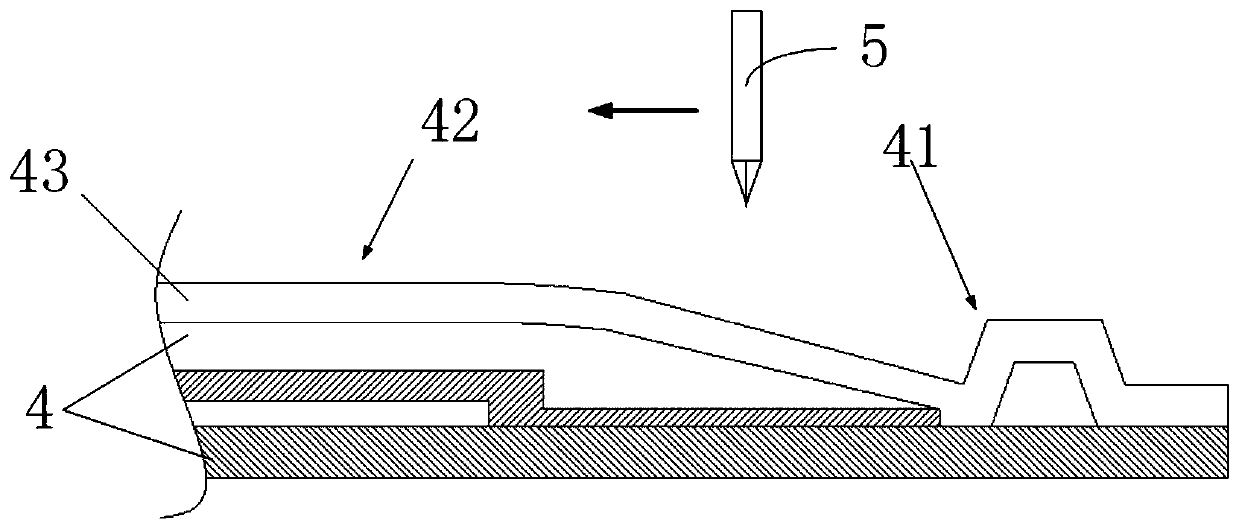

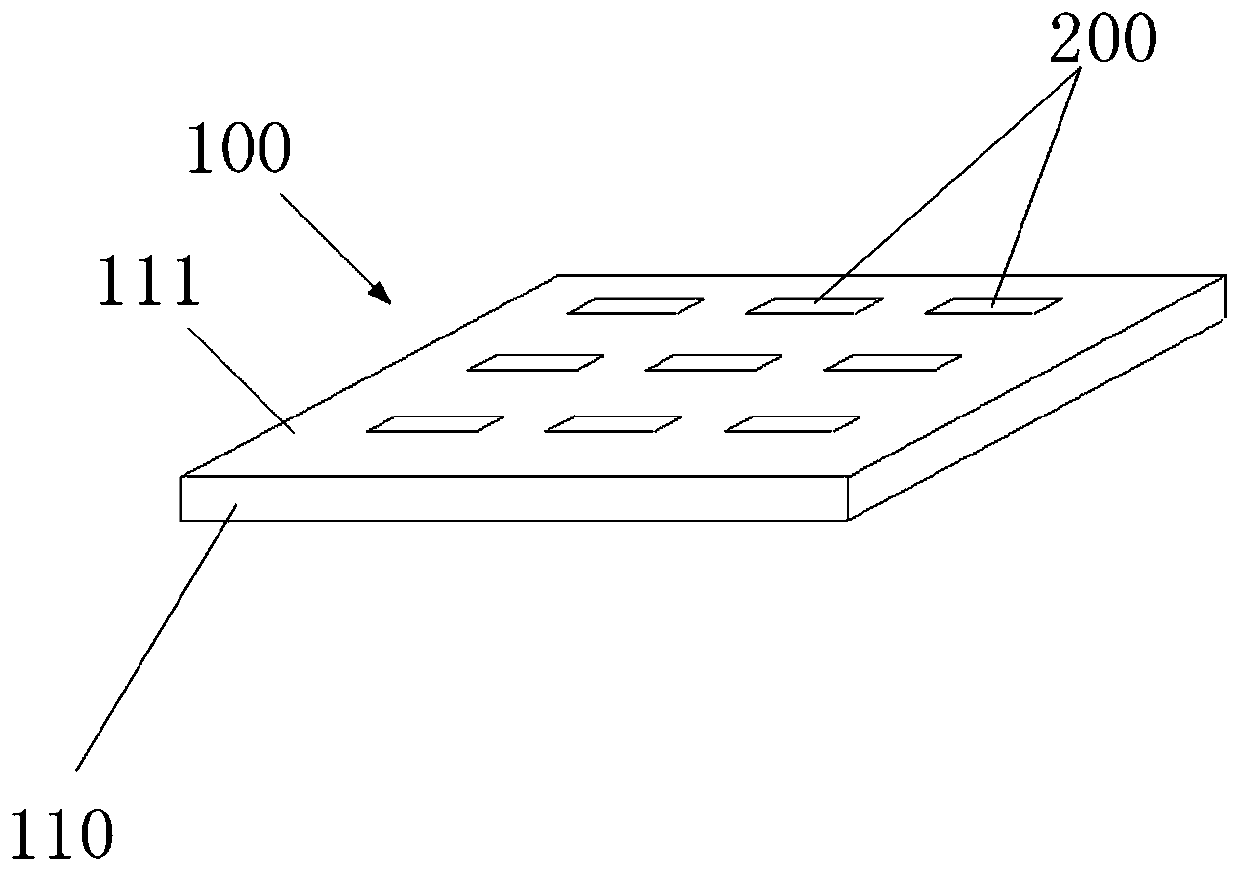

[0041] In order to solve the problem that the printing material in the prior art performs inkjet printing on the edge of the display area, the climbing distance of the printing material at the edge of the display area is too long, which affects the edge light output of the manufactured display panel. The printing table for ink printing changes the way of controlling the fluidity in the printing process through the printing material itself in the prior art. By setting a heat conduction element on the printing table for inkjet printing, it is used to support and place the substrate to be printed. Sub-regional control of print material flow on a substrate.

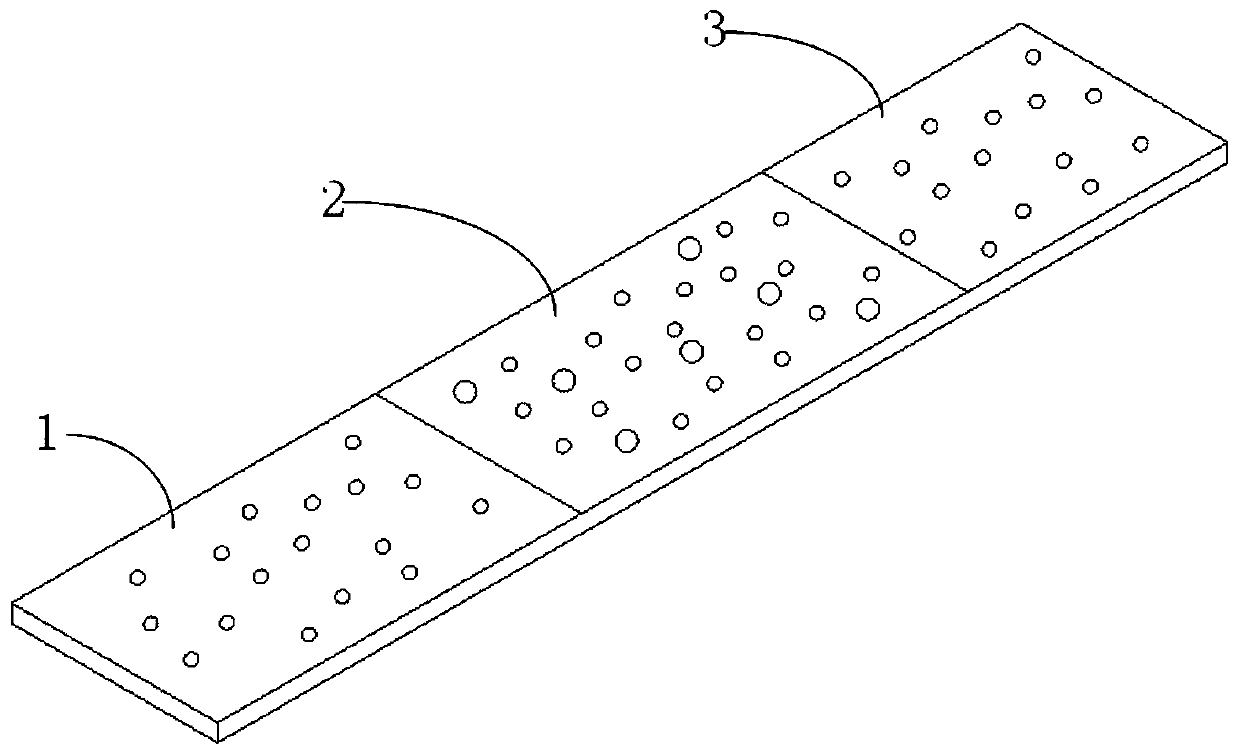

[0042] like image 3 Shown is a three-dimensional schematic diagram of one of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com