Lifting tool clamp roll-over table used for assembly of automobile instrument

A technology for automobile instrument panels and fixtures, applied in workbenches, manufacturing tools, metal processing and other directions, can solve the problems of not very labor-saving, small rotating arm, and no lifting structure of the turning table, so as to achieve labor-saving turning and installation and fixation. Convenient, Dangerous Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

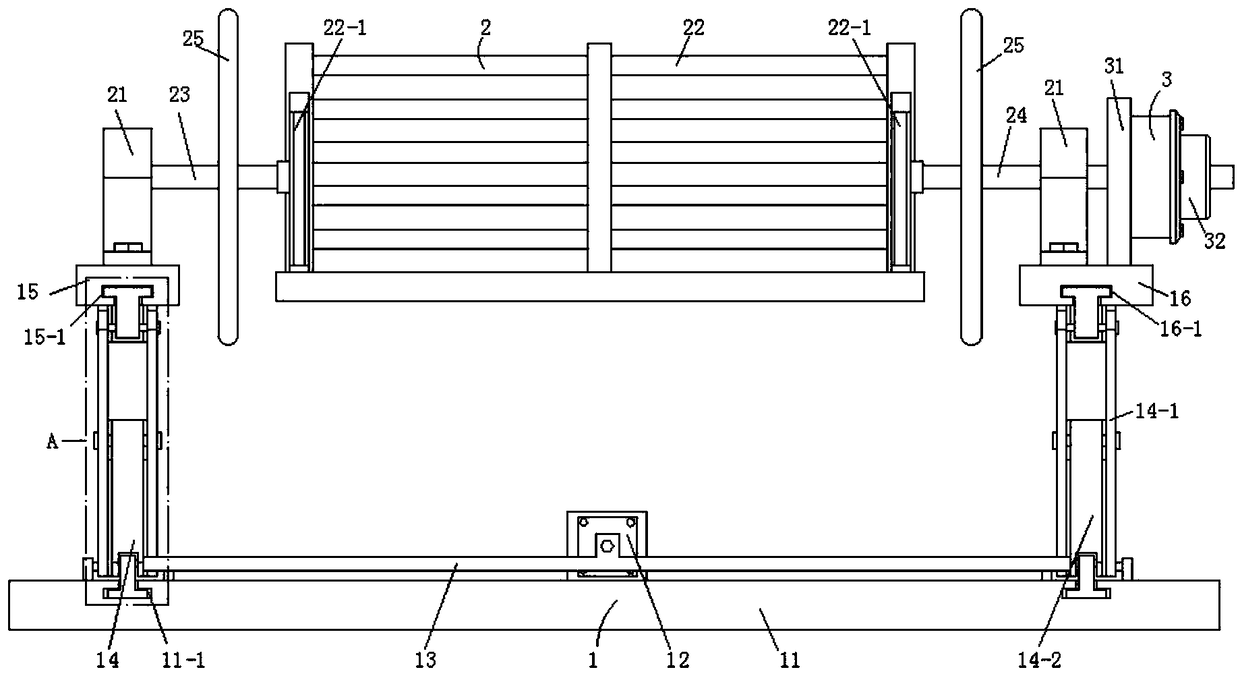

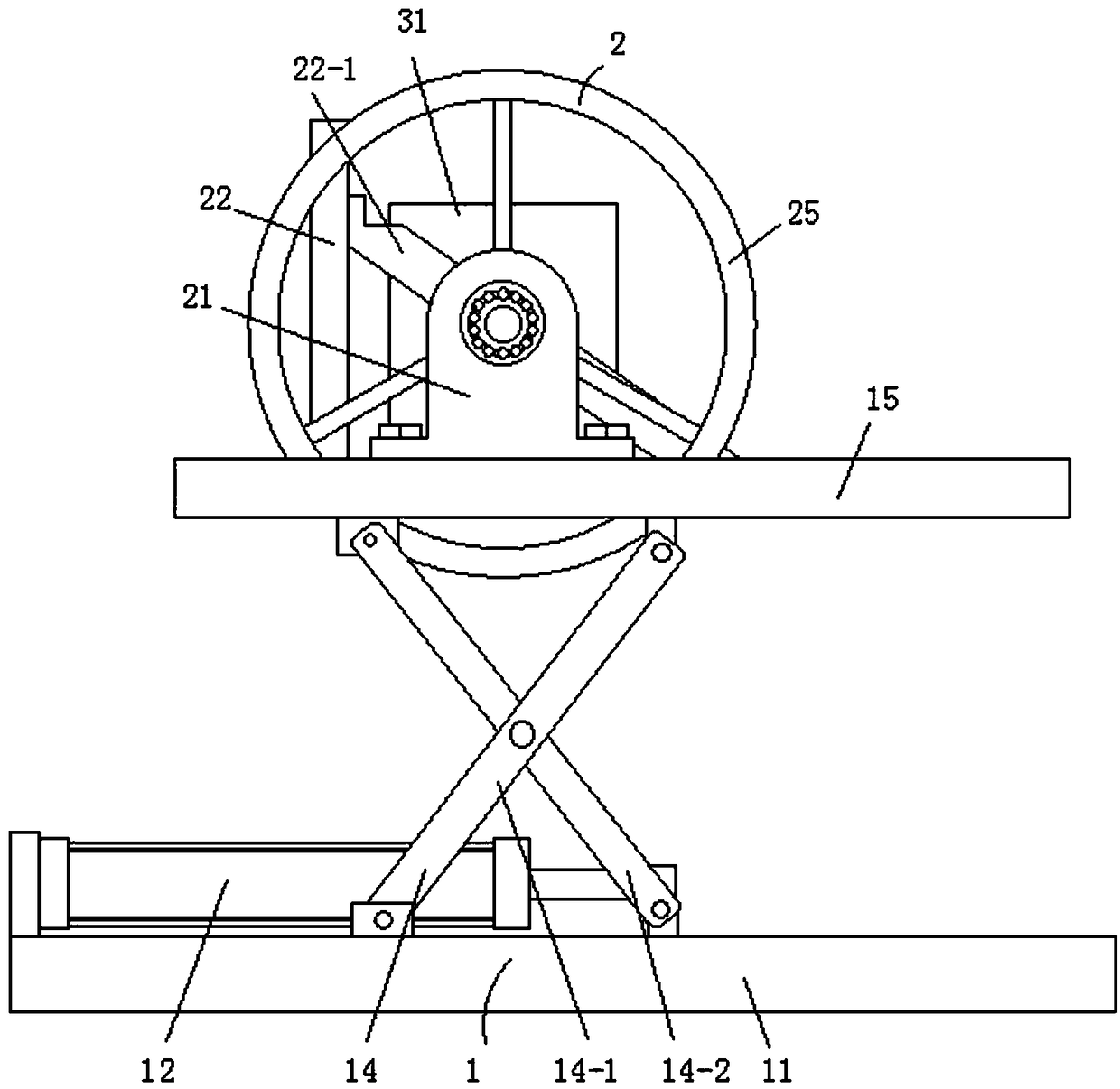

[0020] The structure of the present invention can be used for the turning table of the liftable tooling fixture for the assembly of the automobile instrument panel, which can be used for the turning over of the tooling. The brake disc of the power-off electromagnetic brake 32 is fixedly installed on the second rotating shaft 24, and the housing of the brake is fixedly installed. On the flange fixing plate 31, the assembly tool fixture used for the assembly of the automobile instrument panel is fixedly installed on the tool frame 22. The brake 32 is energized so that it is in the energized and released state, and then the two handwheels 25 are held with both hands to drive the tooling frame 22 to turn over to a suitable position, and then the de-energized electromagnetic brake 32 is de-energized so that it is in the de-energized braking state. Thus, the second rotating shaft 24 is braked and locked by the power-off electromagnetic brake 32, that is, the tooling frame 22 will be ...

Embodiment 2

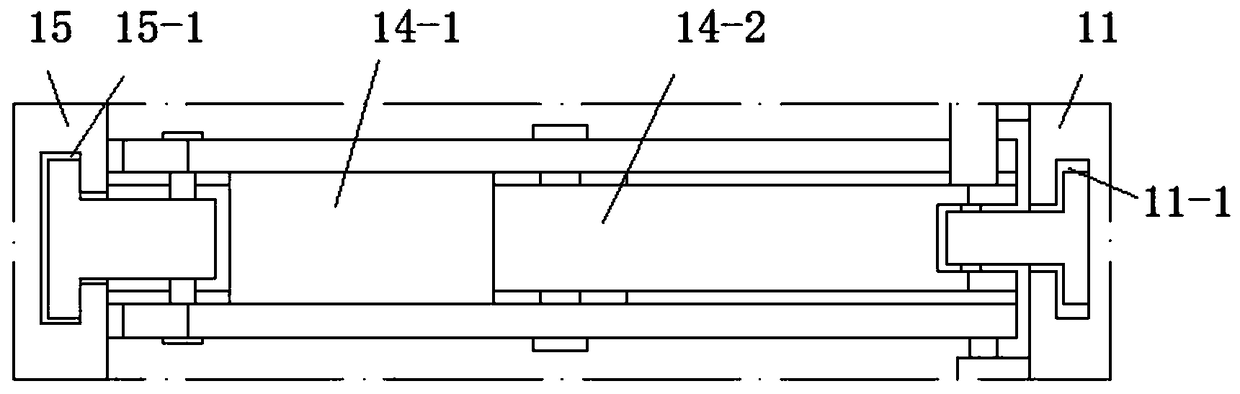

[0022] The structure of the present invention is a liftable jig flip table for the assembly of automobile instrument panels, which has a lifting structure, which can realize automatic lifting. It is very laborious to carry out fixed installation on the tooling frame 22. At this time, the cylinder 12 can be started, and the cylinder 12 will push the connecting rod 13 to move forward, so that the connecting rod 13 will drive two No. 2 rods 14- 2 Sliding along the bottom chute 11-1, and one No. 1 rod 14-1 will slide along the No. 1 chute 15-1, and the other No. 1 rod 14-1 will slide along the No. 2 chute 16-1 , so that the lifting platform mechanism 1 will descend until the lifting platform mechanism 1 drops to the lowest position, and the tooling frame 22 also drops to the lowest position, and then the tooling fixture is fixedly installed on the tooling frame 22. Then the tooling frame 22 is raised. In summary, the lifting structure provided by the turning platform makes the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com