A truck used on a construction site

A technology for construction sites and trucks, which is applied in the field of trucks, and can solve problems such as difficult control, dislocation slipping, and no anti-skid brakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

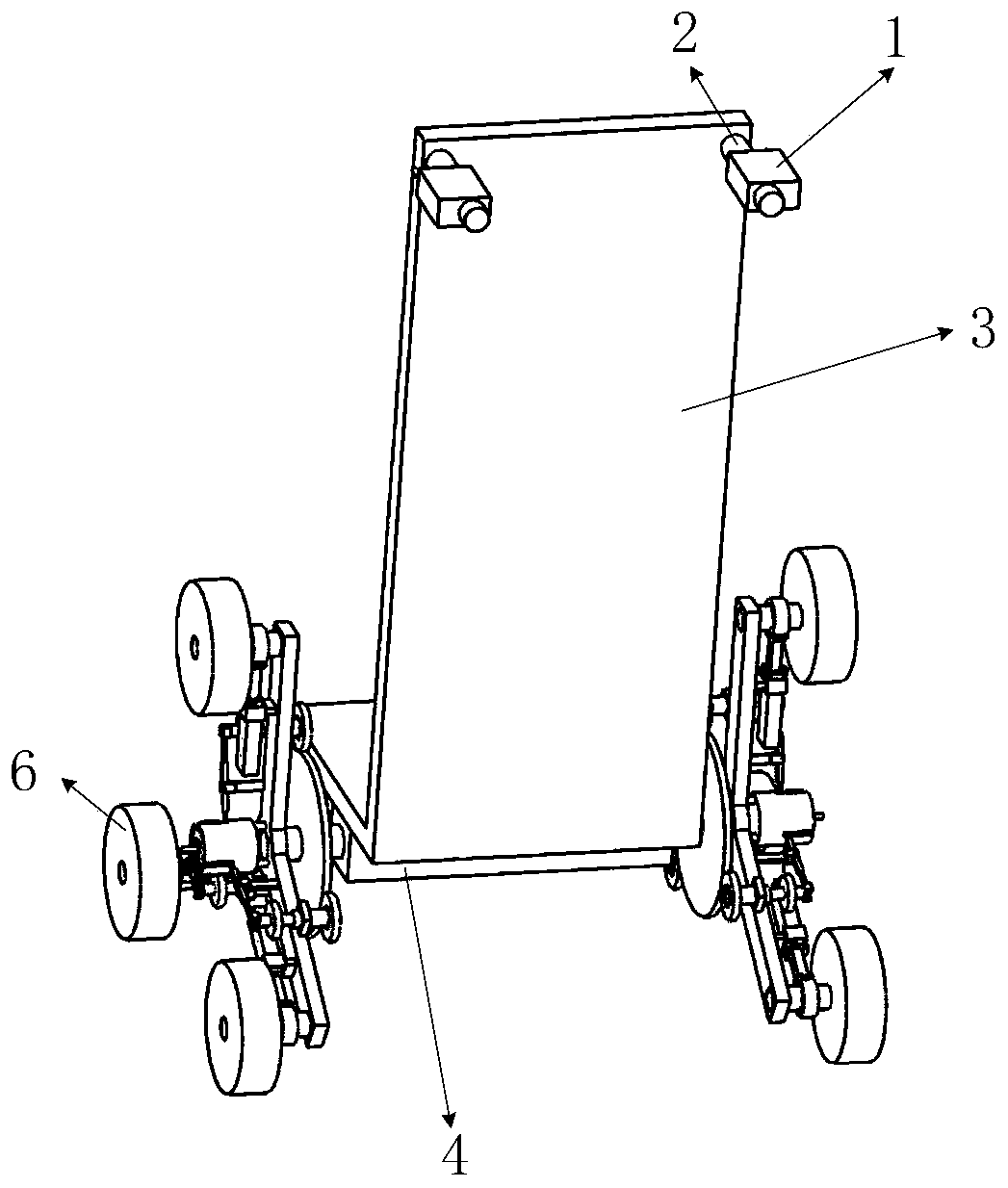

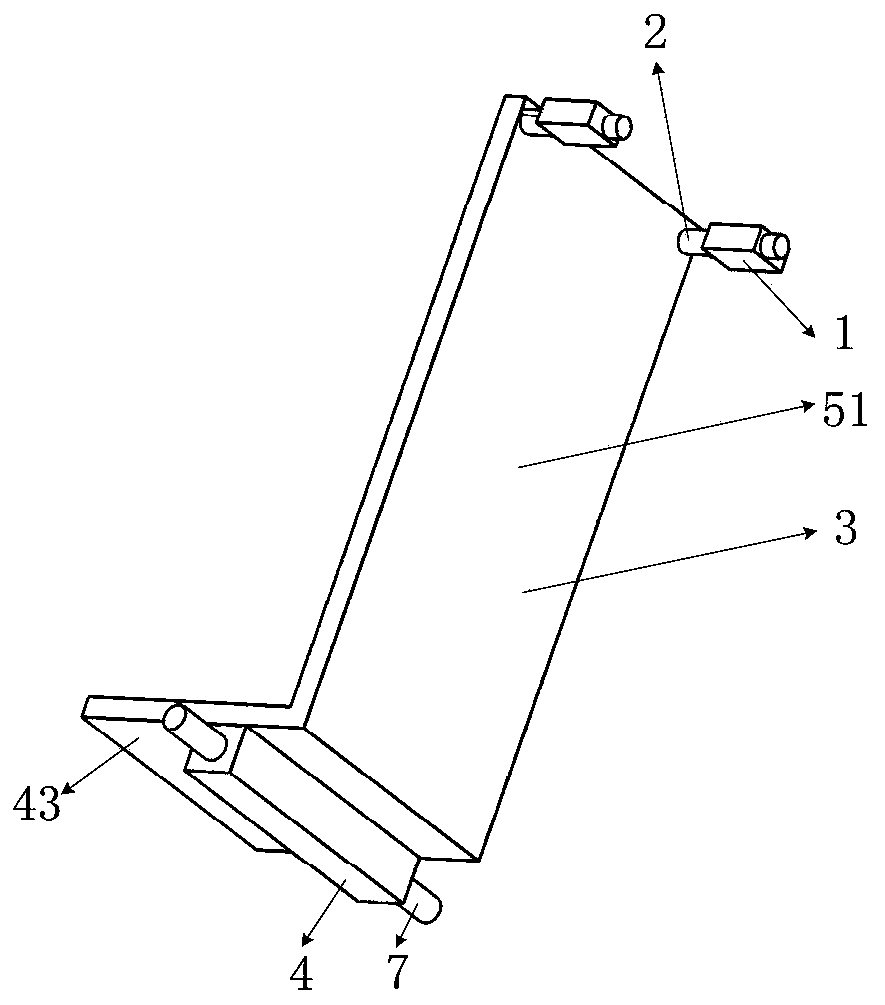

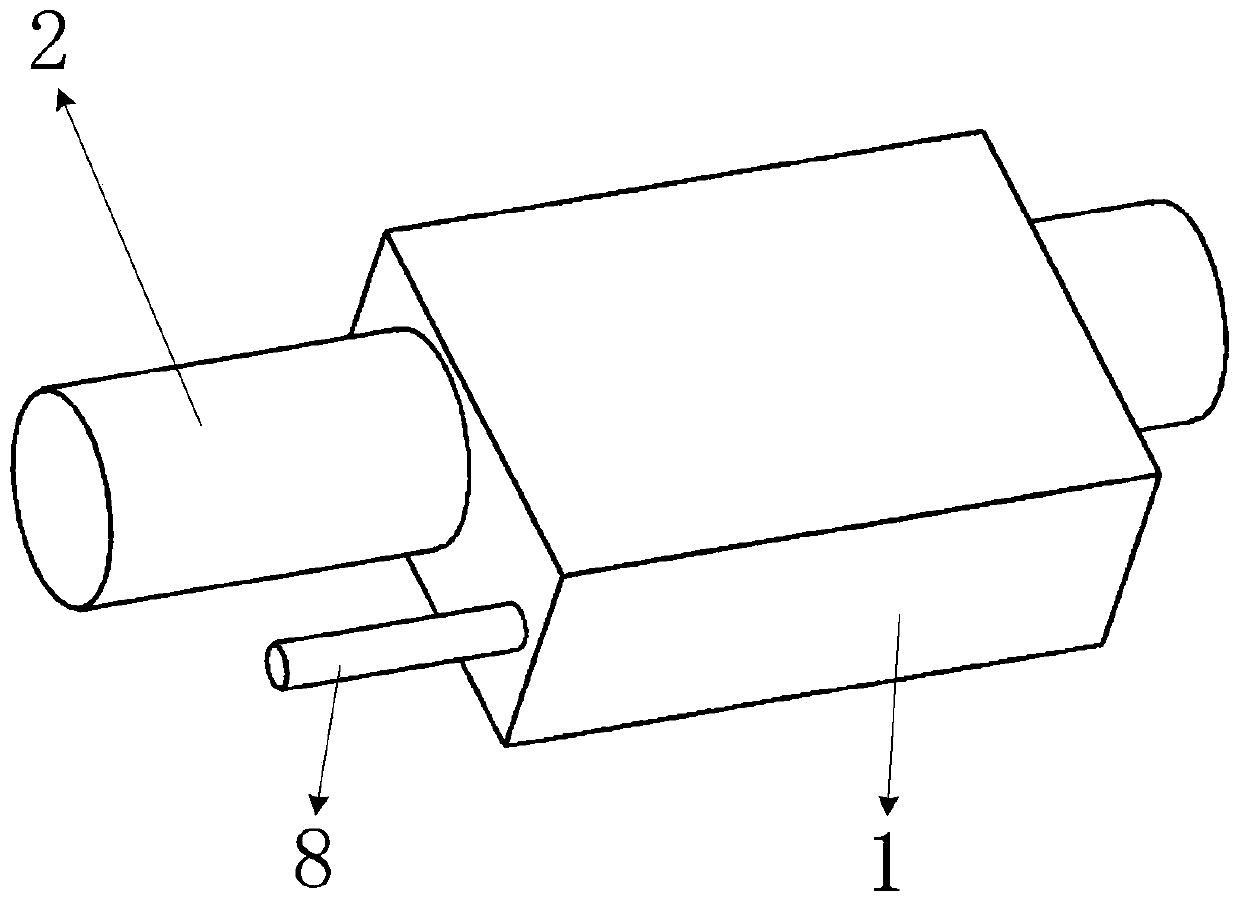

[0057] Such as figure 1 , 2 , 3, it includes hand brake 1, handle 2, L-shaped car plate 3, support block 4, star wheel mechanism 6, support shaft 7, line pipe 8, gear plate 9, as figure 2 As shown, wherein the L-shaped car plate 3 is made of a base plate 43 and a riser 51; as figure 1 , 2 As shown, a support block 4 is installed on the lower surface of the base plate 43 of the L-shaped vehicle panel 3; two handles 2 are symmetrically installed on both sides of an end of the vertical plate 51 of the L-shaped vehicle panel 3 away from the support block 4; image 3 As shown, each handle 2 is equipped with a hand brake 1; figure 2 As shown, two support shafts 7 are symmetrically fixedly installed on both sides of the support block 4; Figure 4 , 5 As shown, each support shaft 7 is equipped with a star wheel mechanism 6 at one end away from the support block 4; a toothed disc 9 is fixedly installed on the outer surface of each support shaft 7, and the tooth disc 9 is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com