Automatic feeding mechanism for bend pipe polishing robot

An automatic feeding and robot technology, applied in the polishing field, can solve problems such as reducing production costs and disadvantages, and achieve the effects of reducing production costs, improving polishing efficiency, and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

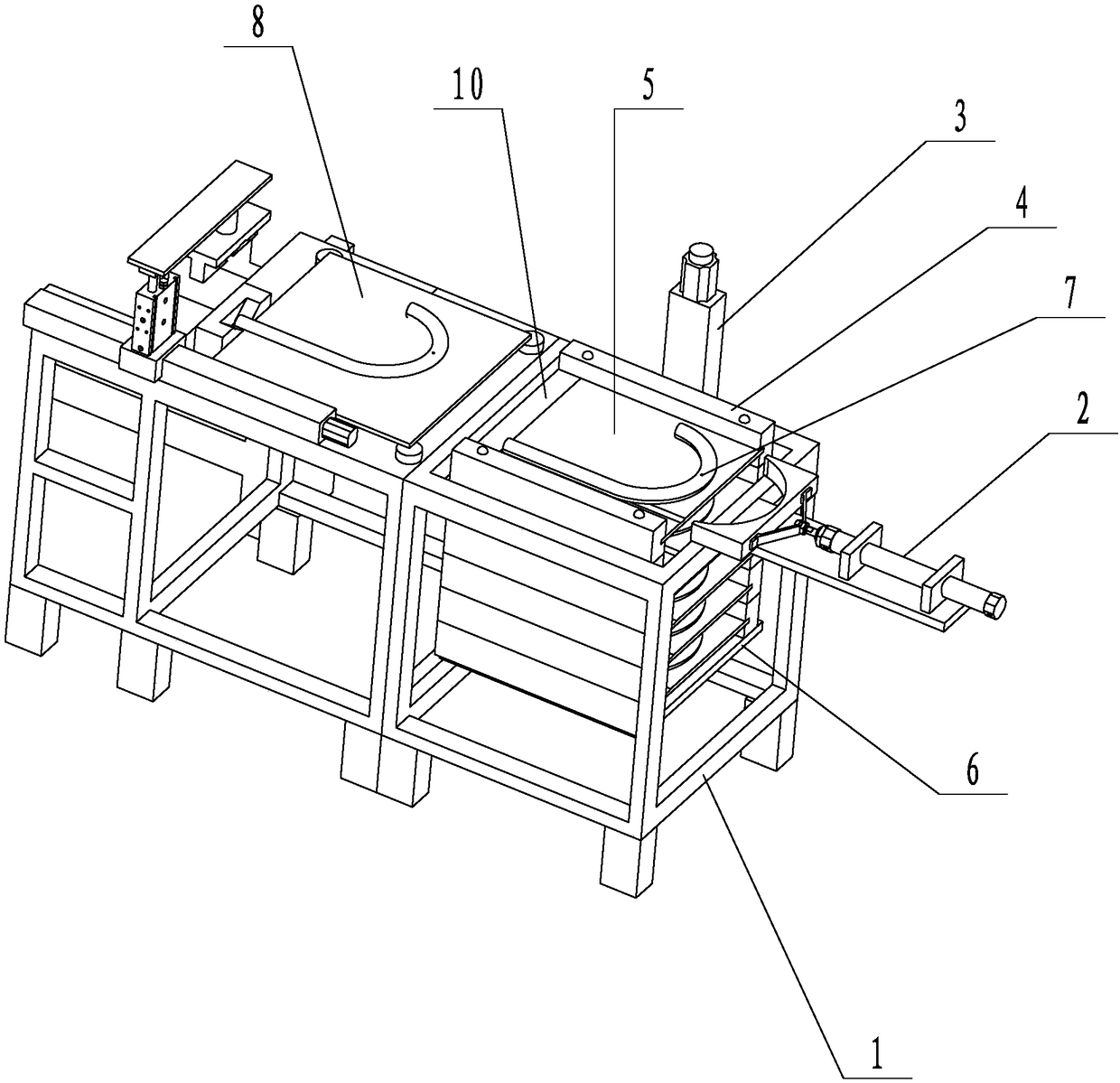

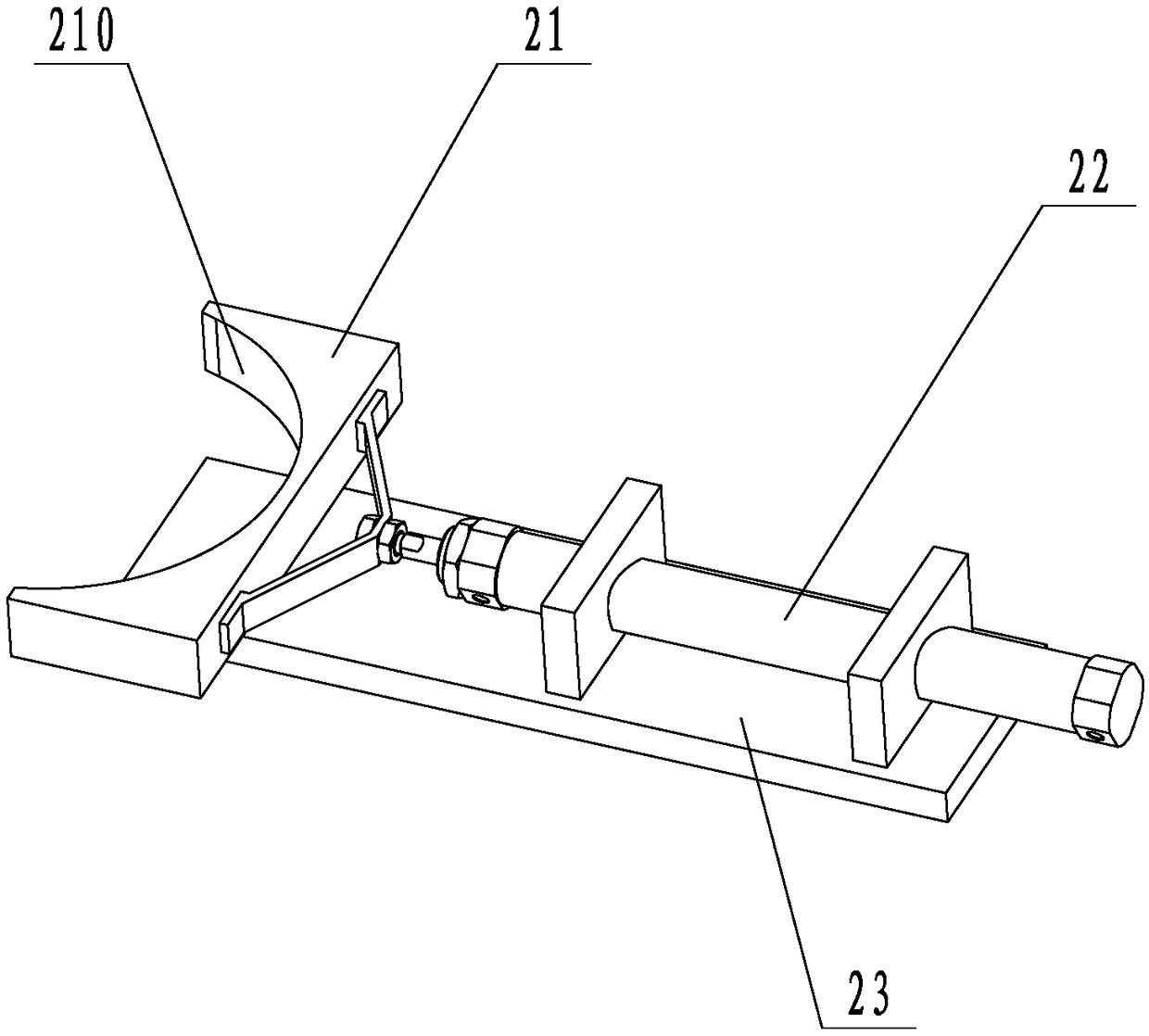

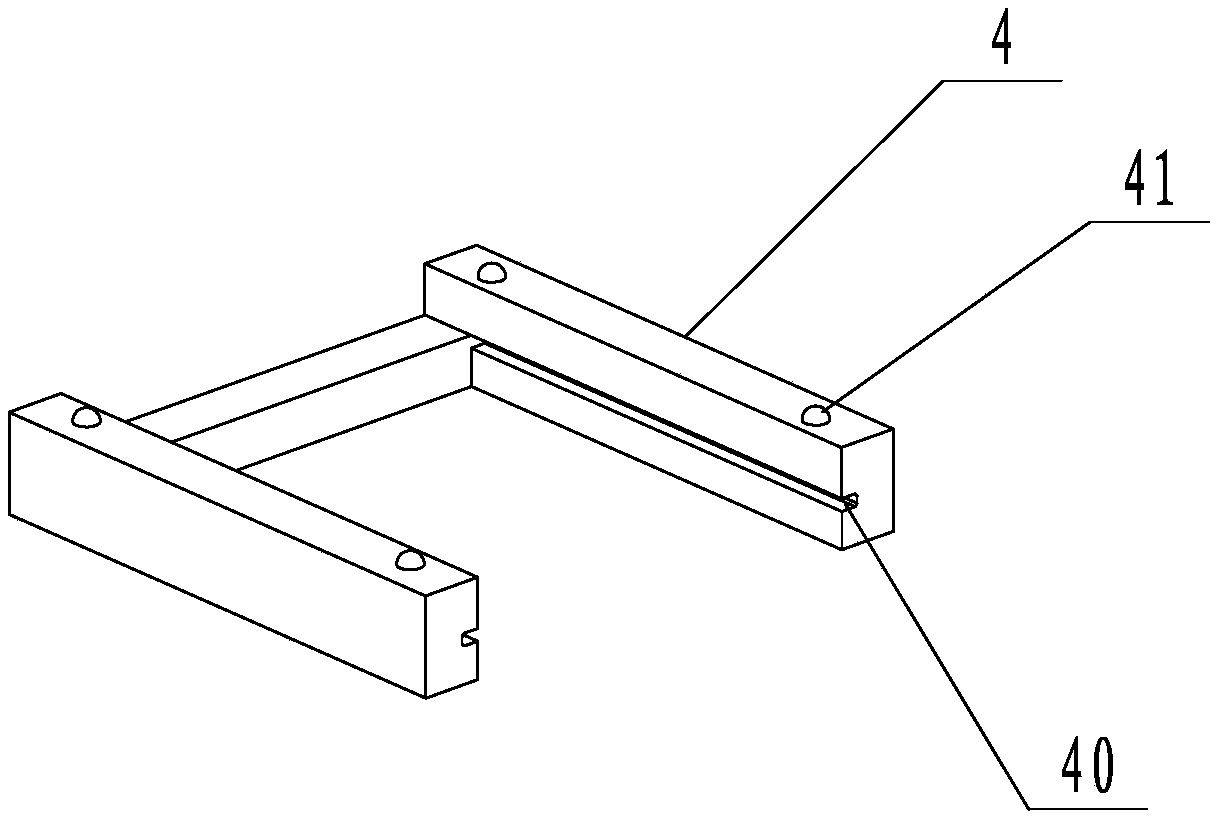

[0018] refer to Figure 1 to Figure 6 , an automatic feeding mechanism for a curved pipe polishing robot of the present invention, comprising a base 1, the base 1 is provided with a feeding area 10, the base 1 is preferably a frame structure, and the feeding area 10 is arranged in the middle of the frame structure , the loading area 10 is provided with a loading frame, and the loading frame is connected with a vertical driving mechanism 3 that can drive it to move vertically in the loading area 10. The vertical driving mechanism 3 can be a servo motor or It is a cylinder or other driving mechanism. The vertical driving mechanism 3 can be equipped with a sensor. When the vertical driving mechanism 3 drives the loading frame to rise to the set distance, the sensor sends a signal to the vertical driving mechanism 3 to stop it. The frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com