Battery feeding mechanism of storage battery subsequent unmanned packing device

A technology of feeding mechanism and battery, applied in packaging and other directions, can solve the problems of neglect, heavy battery weight and high price, and achieve the effect of reducing cost, simple mechanism structure and low production and processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

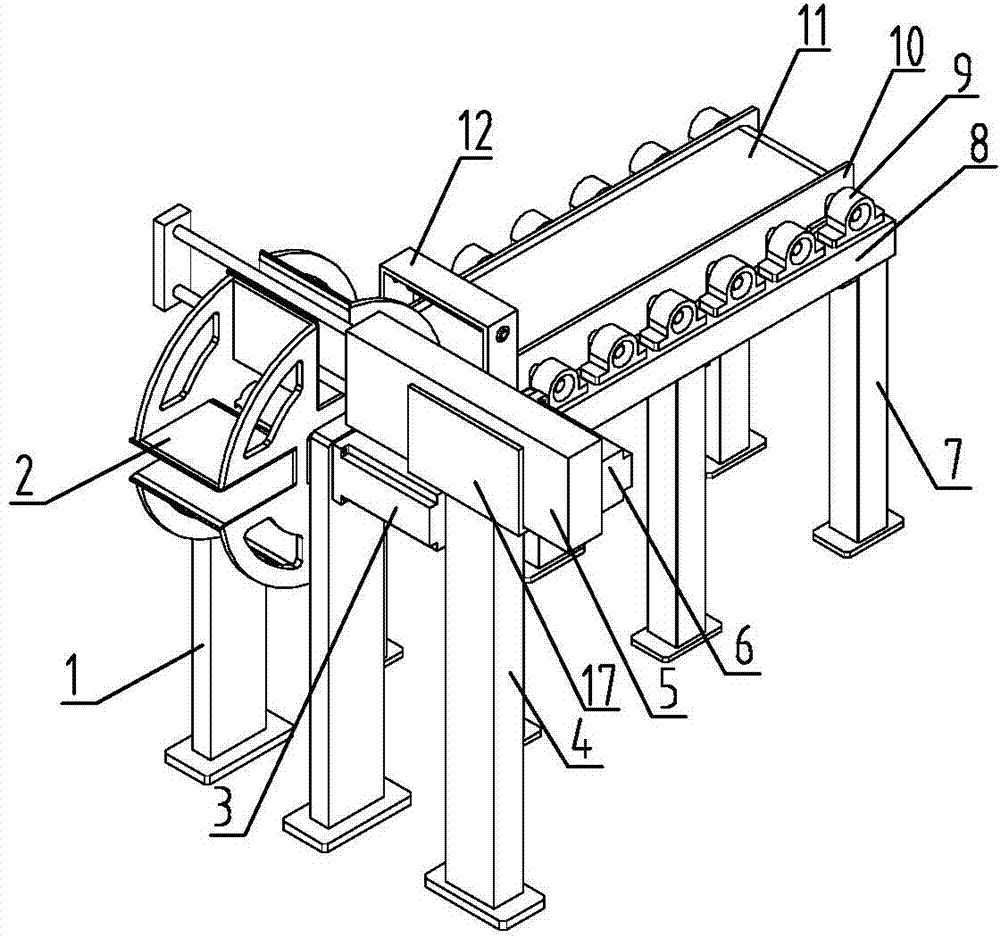

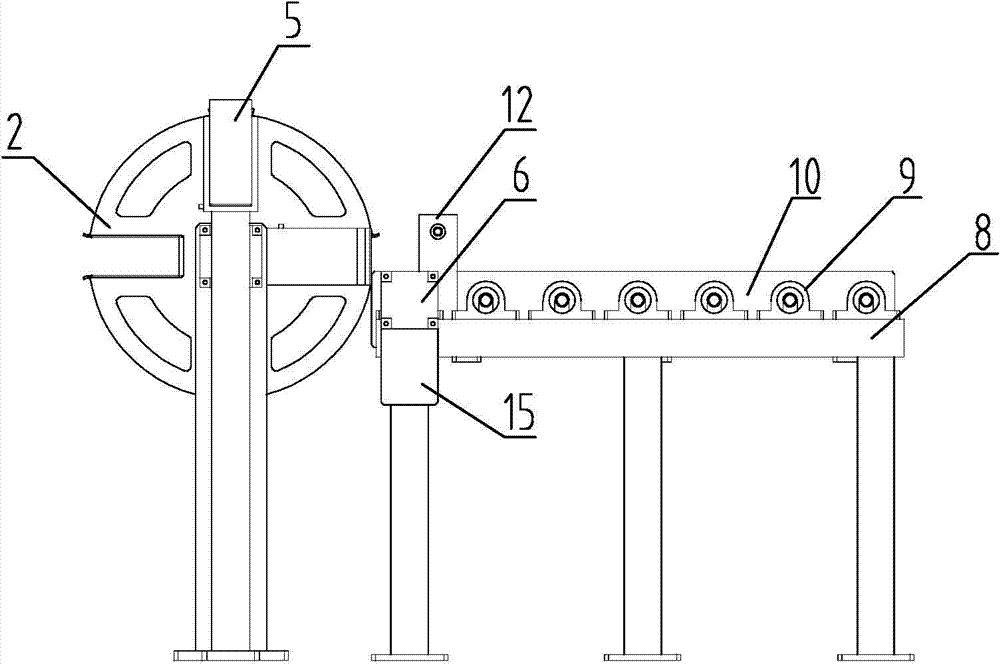

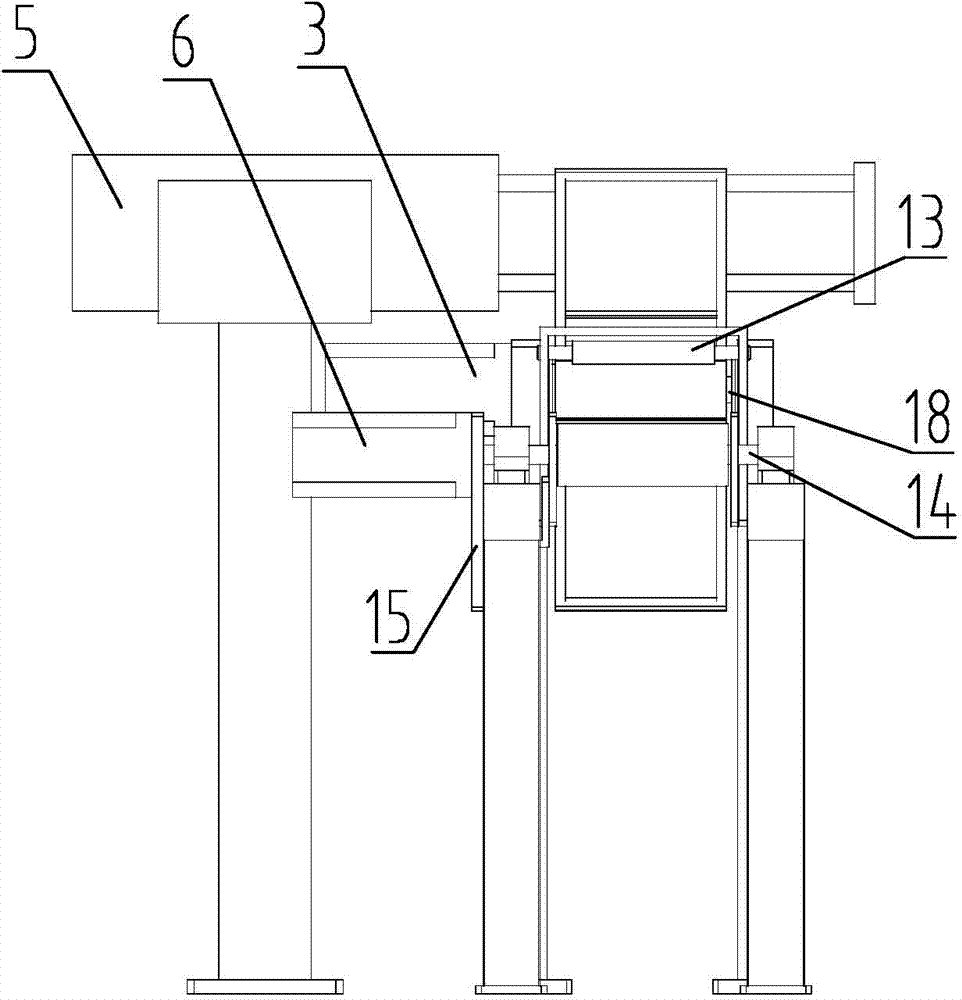

[0013] Such as figure 1 -- Figure 4 As shown, the feeding mechanism of the storage battery rear unmanned packaging equipment in this embodiment includes a biaxial cylinder 5, a cylinder support 17, a servo motor 3, a cylinder column 4, and two distribution trays Column 1, a material distribution tray 2, two baffle plates 10, a rotating main shaft 18, and a belt conveying device, the biaxial cylinder 5 is installed on the cylinder support 17, and the cylinder support is fixed On the cylinder column 4, the rotating main shaft 18 is installed between the two distribution tray columns 1, the described material distribution tray 2 passes through the rotating main shaft 18, and the output shaft of the servo motor 3 is connected to the The rotating main shaft 18 is connected with a shaft coupling, and the material distribution tray 2 is evenly distributed with four gaps. The belt conveying device includes 7 driven roller shafts 16, a main roller shaft 14, and a reduction motor 6. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com