Self-centering hole inner clamping device capable of achieving automatic compensation and tension maintaining during part heating

An automatic compensation and self-centering technology, applied in workpiece clamping devices, auxiliary devices, metal processing equipment, etc. The effects of axial displacement and radial runout, guaranteed processing quality and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

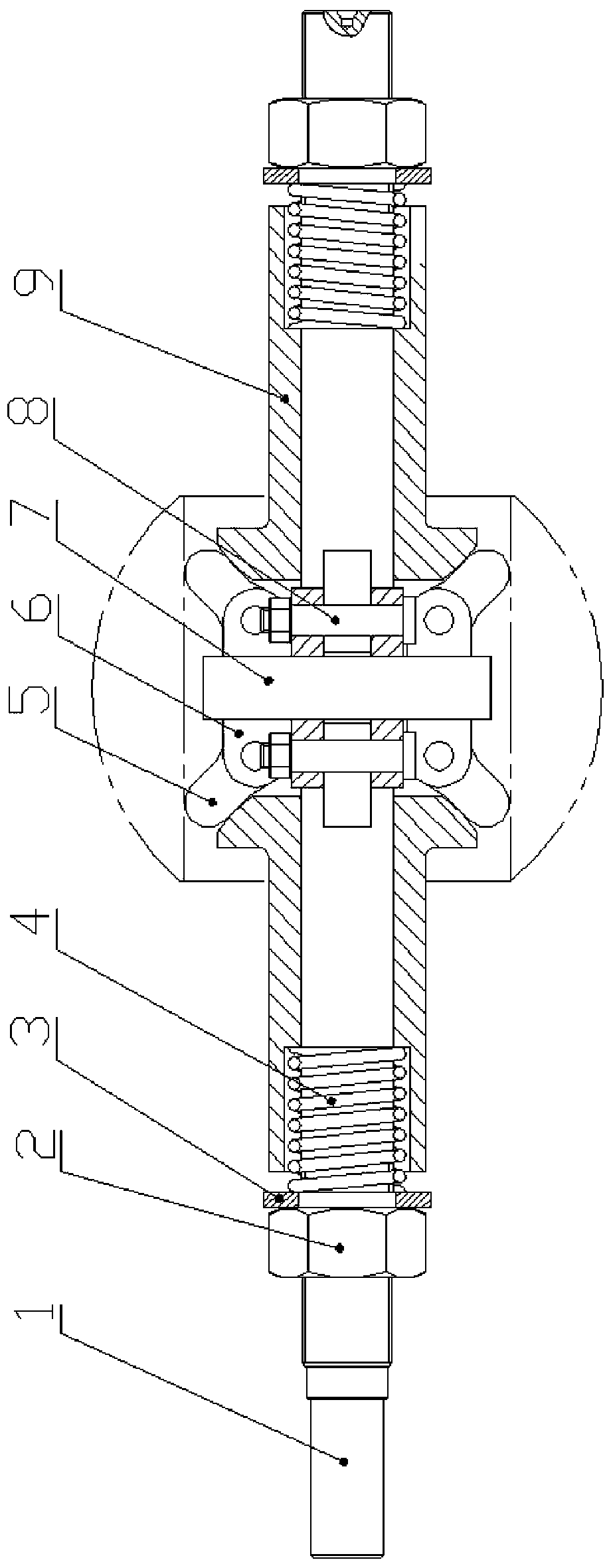

[0035] see Figure 1 to Figure 9 , a self-centering hole clamping device that automatically compensates and maintains tension when the part is heated, including a centering shaft 1, and a flange 7 for installing an expansion claw 5 is provided on the centering shaft 1, and the protrusion The circumference of the edge 7 is provided with a lifting groove 7-1. The hoisting groove 7-1 has facilitated the hoisting and hoisting of larger parts, and the hoisting groove 7-1 has formed a way for the iron chain when passing through the part endoporus. At least three hinged seats 6 are evenly distributed around the axis on the axial end surface of the flange 7 , each hinged seat 6 is hinged with an expansion claw 5 respectively. The hinged seat 6 includes two symmetrically arranged brackets 6-1, and the expansion claw 5 is arranged between the two brackets 6-1. The fixed end 5-2 of the expansion claw 5 and the hinged seat 6 are hinged by bolts 8, and the two brackets 6-1 of the hinged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com