Handle, fixed transport mechanism and special-shaped ribbon feeding device

A conveying mechanism and special-shaped welding technology, which is applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problem of inability to load special-shaped welding strips, and achieve the effect of quick and sensitive response and favorable stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following description is only for disclosing the present invention to enable those skilled in the art to practice the present invention. The embodiments in the following description are only examples, and those skilled in the art can think of other obvious modifications. The basic principles of the invention defined in the following description can be applied to other embodiments, variations, improvements, equivalents and others without departing from the spirit and scope of the invention.

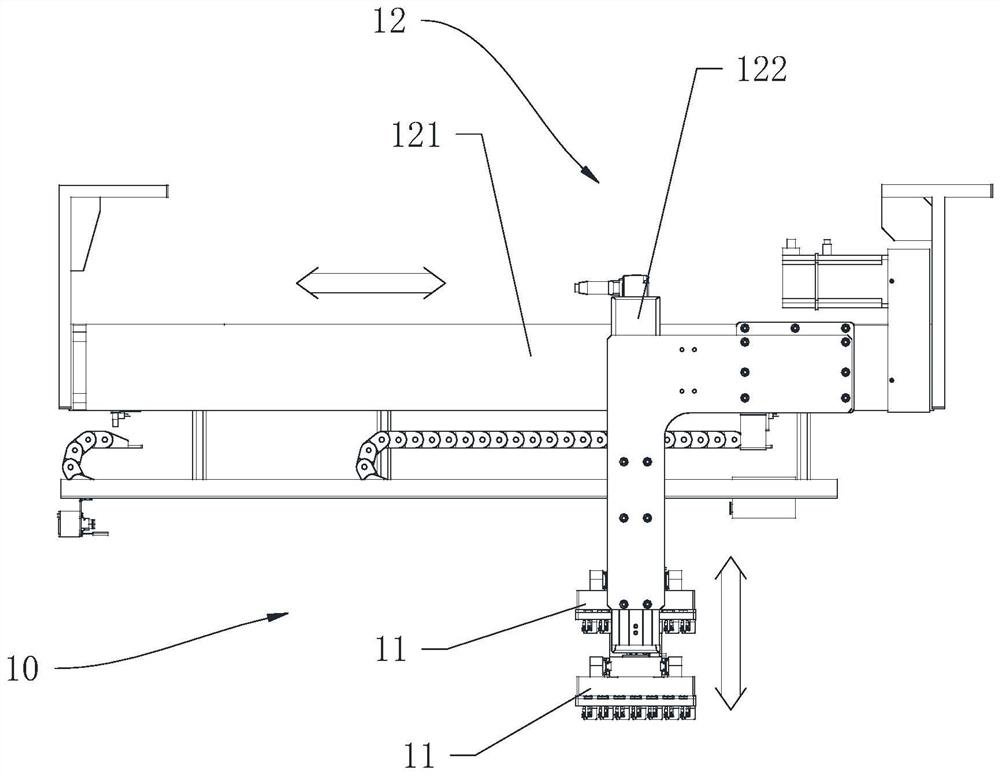

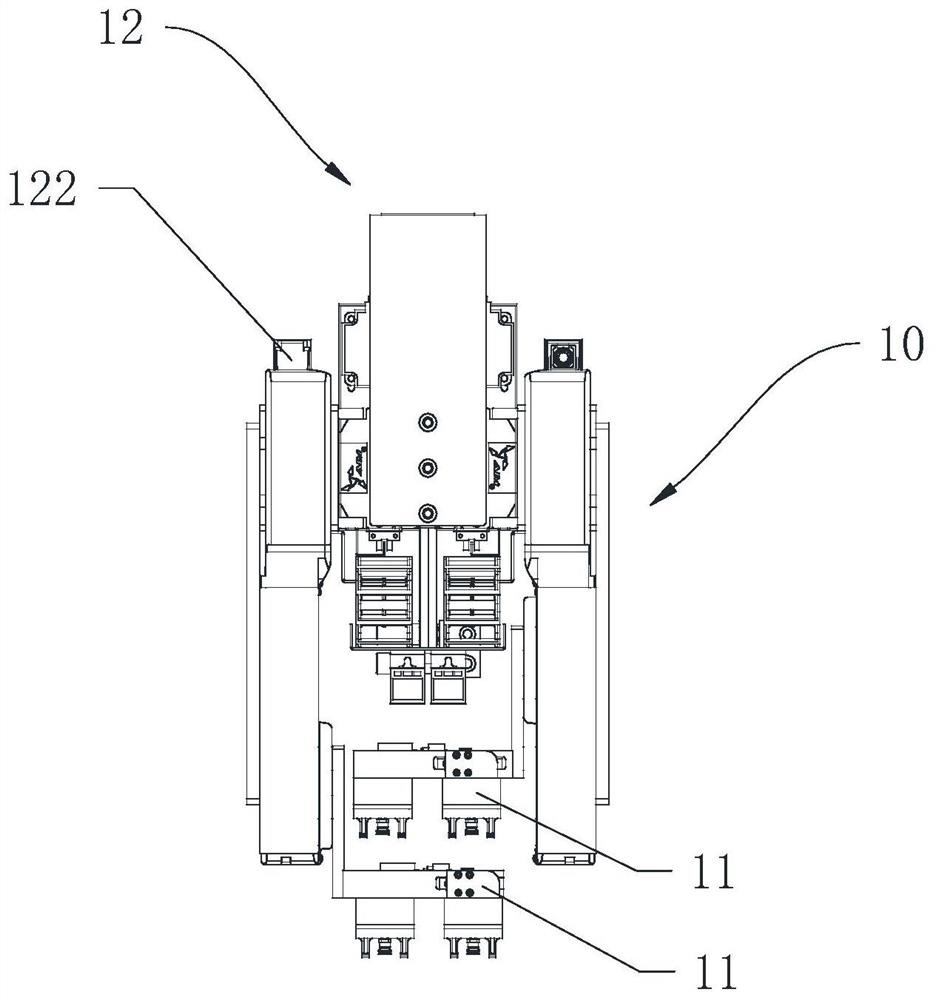

[0035] Such as figure 1 with figure 2 As shown, the present invention provides a fixed transport mechanism 10. The fixed transport mechanism 10 is used to fix and transport the special-shaped ribbon, especially to feed the special-shaped ribbon to the welding platform during the solar cell sheet welding process, so as to facilitate the subsequent special-shaped Soldering of ribbons and solar cells. The fixed transport mechanism 10 includes a handle 11 and a moving module 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com