Multi-plasmid activation and vibration equal-thick flip-flow screen

A relaxation screen and mass body technology, applied in the field of screening machinery and equipment with screen surface relaxation, and thick relaxation screens, can solve the problems of large dynamic load of the foundation, high manufacturing cost of parts, large driving power, etc., and achieve low power consumption. Dynamic load, force energy saving, damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

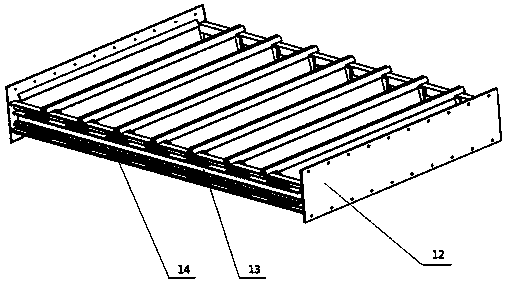

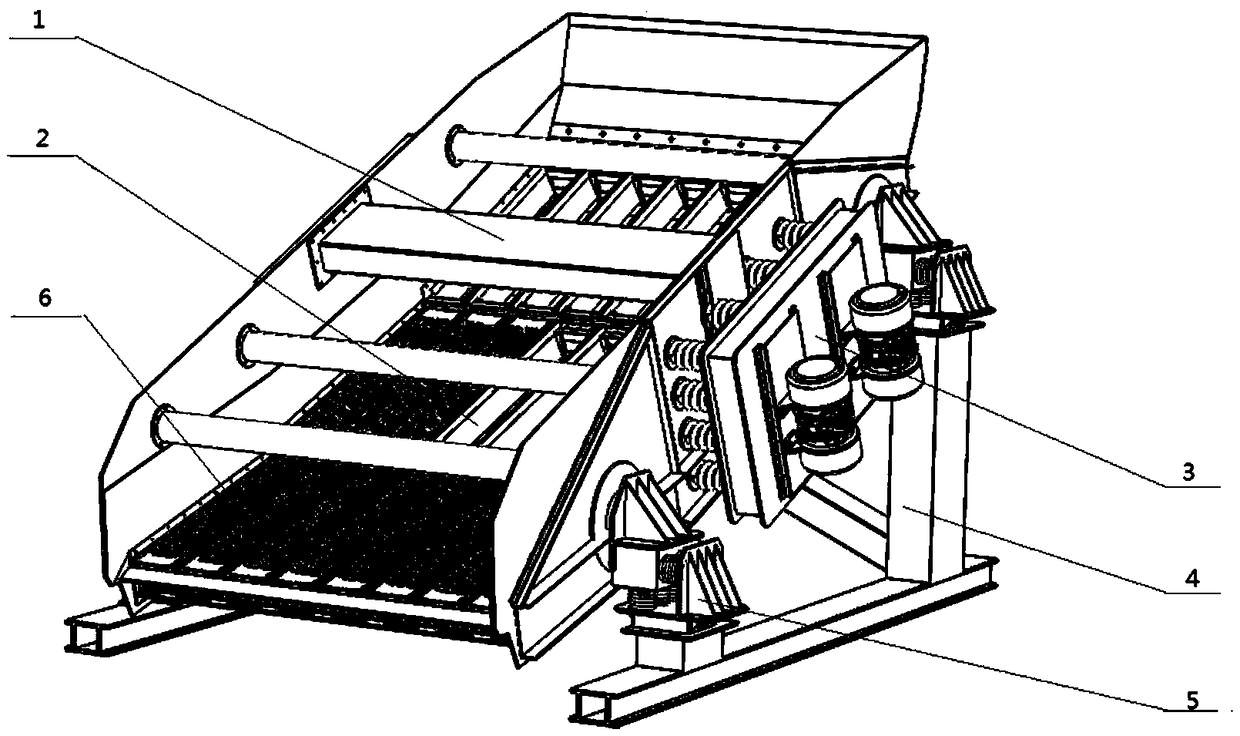

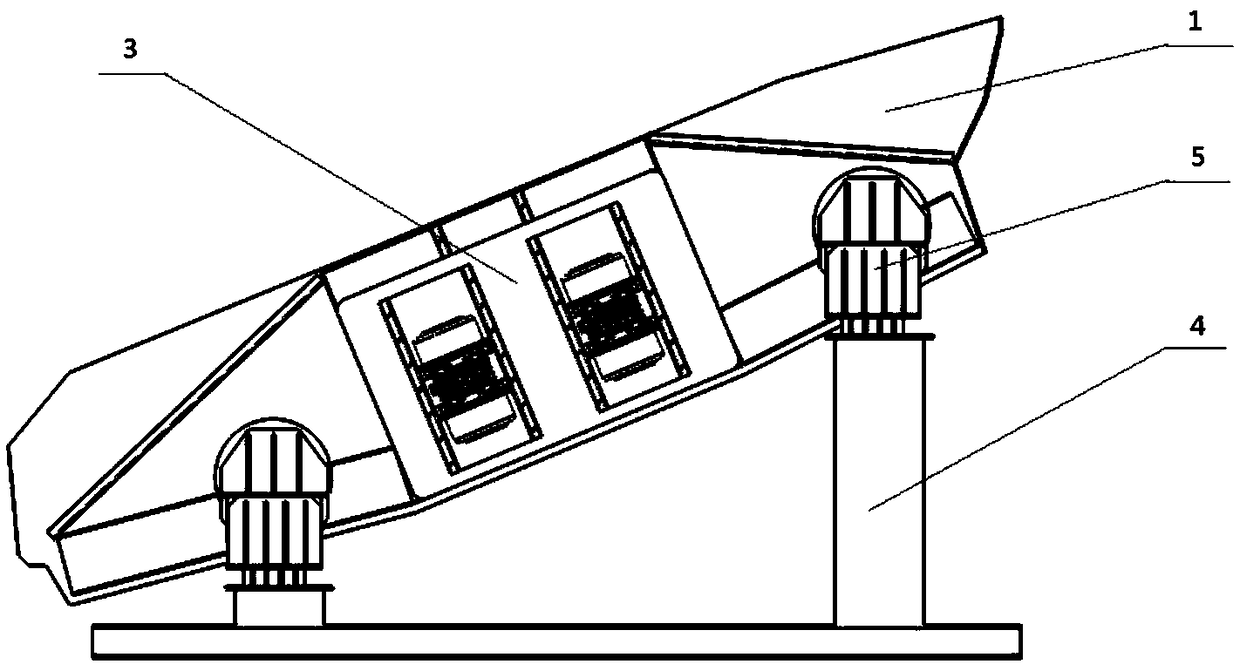

[0024] Such as figure 1 and figure 2 As shown, the iso-thick relaxation sieve for multimass activation, which includes an outer screen frame (1), a relaxation body (2), an excitation device (3), a support frame (4), a T-shaped spring vibration isolation device (5 ) and polyurethane sieve plate (6). The three relaxation bodies (2) are installed in the side plate (8) of the outer screen frame (1) through the flanges on both sides of the relaxation body (2) at 15°, 20°, and 25° to the horizontal plane, so that the whole is The banana-shaped screen surface is 15°, 20°, 25°, and the angle can be changed appropriately for screening different materials. Between the main vibrating spring (21) of the excitation device (3) and the outside of the outer screen frame (1), it is fixed with bolt compression, so that the vibration excitation device (3) is installed on the outer sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com