Crop straw crusher

A technology of crop straw and pulverizer, which is applied in the field of straw pulverization, can solve the problems of dead corners and uneven thickness of crushed powder, and achieve the effect of good cutting effect, reducing dead corners and thorough cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In describing the present invention, it should be understood that the terms "upper", "lower", "front", "rear", "left", "right", "top", "bottom", "inner", " The orientation or positional relationship indicated by "outside", etc. is based on the orientation or positional relationship shown in the drawings, and is only for the convenience of describing the present invention and simplifying the description, rather than indicating or implying that the referred device or element must have a specific orientation, so as to specific orientation configuration and operation, and therefore should not be construed as limiting the invention

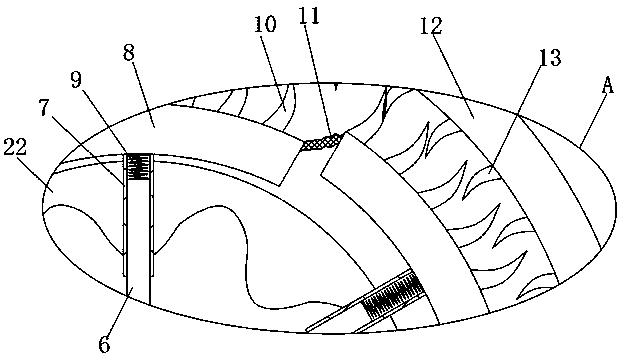

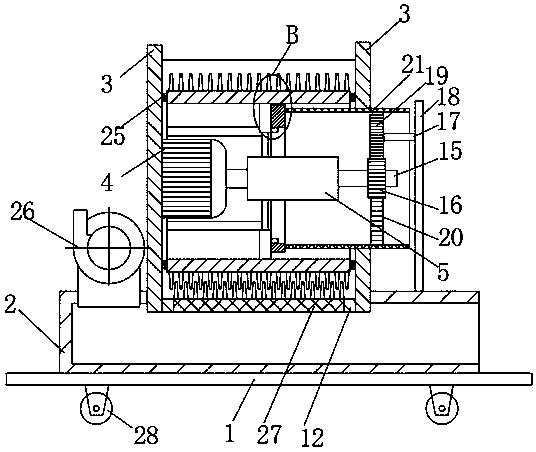

[0030] refer to Figure 1-5 , a crop straw grinder, comprising a bottom plate 1, a crushing bin 2 is welded on the bottom plate 1, two side plates 3 are welded on the upper end of the crushing bin 2, and a motor 4 is installed on the side plate 3 on the left side using bolts, The output shaft of the motor 4 is welded with a center wheel 5, and ...

Embodiment 2

[0039] The difference between Embodiment 2 and Embodiment 1 is that: the left end of the crushing bin 2 is equipped with a fan 26 using bolts, the air inlet end of the fan 26 communicates with the outside world, and the blowing end of the fan 26 is connected to the inside of the crushing bin 2. The right wall of the warehouse 2 is open. When the device is placed in the field, the fan 26 can directly blow the crushed stalks to the field, and return them to the field without manual handling of the crushed stalks. .

Embodiment 3

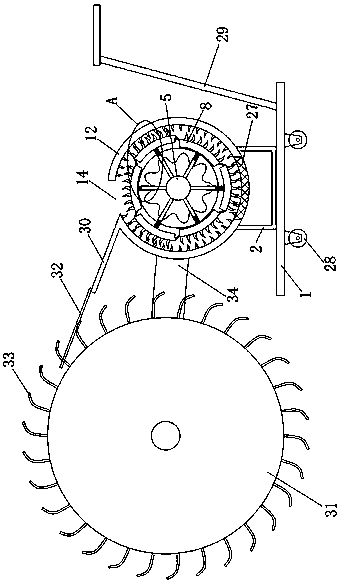

[0041] The difference between the third embodiment and the second embodiment is that four rollers 28 are symmetrically welded on the bottom surface of the bottom plate 1, and a push handle 29 is welded on the bottom plate 1, which is convenient for the user to push the device in the field. Both side plates 3 are welded There is a connecting plate 34, and the two connecting plates 34 are jointly connected with a pin shaft to rotate and connect with a material receiving barrel 31, and the outer wall of the material receiving barrel 31 is evenly welded with a plurality of thin claws 33, and the edge of the feeding port 14 is welded with a material guide plate 30, A plurality of steel wires 32 are welded on the material guide plate 30. When there are many straws scattered in the field, there is no need to manually store the straws into the feeding port 14. The user only needs to push the device until the straws are scattered. At this time, the receiving barrel 31 rolls along the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com