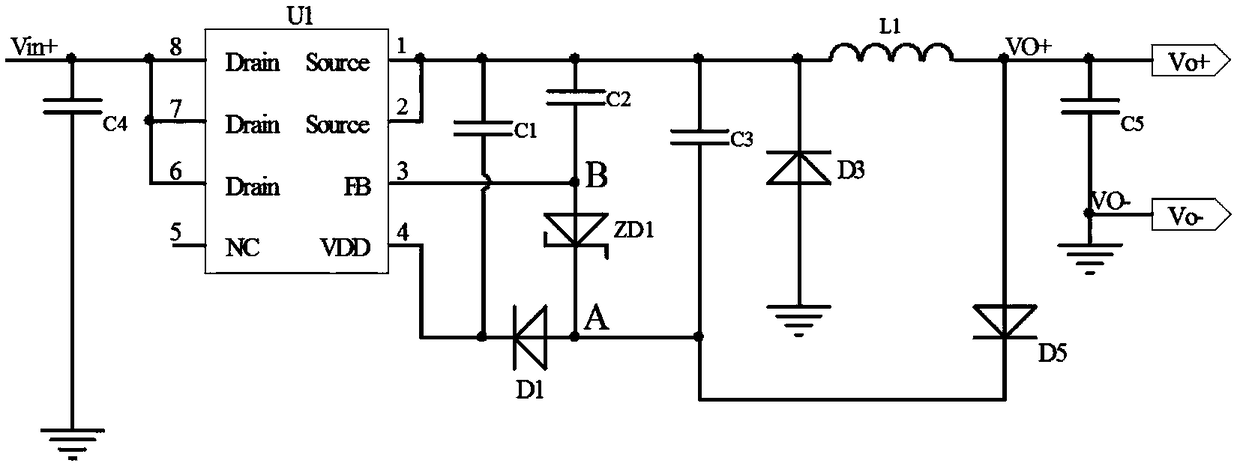

Output voltage feedback circuit and temperature compensation circuit of switching converter

A temperature compensation circuit and switching converter technology, applied in the direction of output power conversion devices, electrical components, etc., can solve the problems of unsatisfied and variable voltage accuracy, and achieve a wide range of acquisition channels, stable voltage accuracy, and simple design principles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

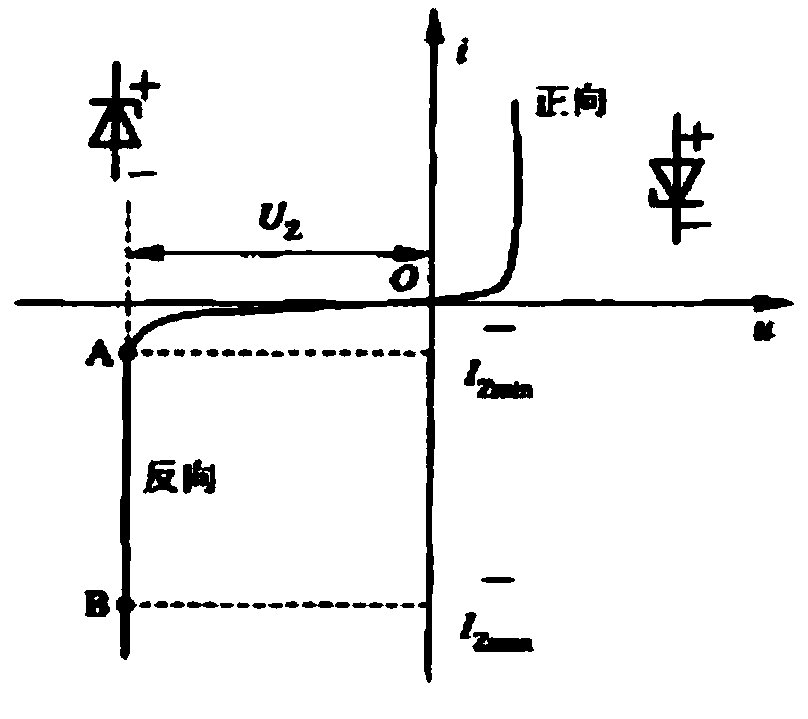

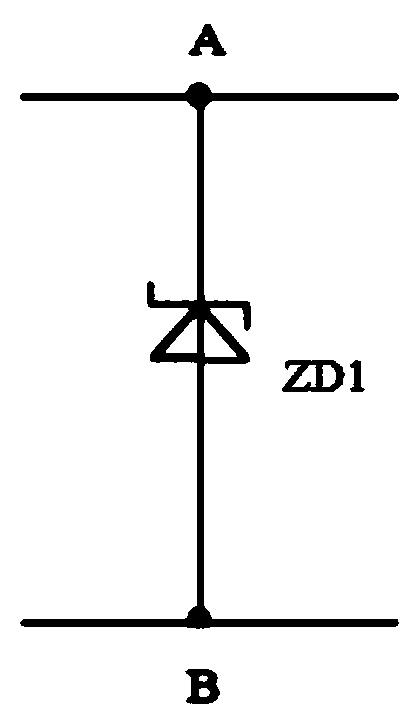

[0038] The temperature compensation circuit of the output voltage feedback circuit of Embodiment 1 of the present invention utilizes NTC resistors (also known as negative temperature coefficient thermistors) to perform temperature compensation on positive temperature characteristic regulator tubes, such as Figure 4 shown. The circuit connection method: Figure 4 Node C is connected to the common node of the resistor R11 and the NTC resistor, and the common node of the other end of the resistor R11 and the NTC resistor is connected to the cathode of the Zener diode ZD11, and then connected to the D node through the anode of the Zener diode ZD11. Will Figure 4 Circuit replacement between C and D nodes figure 1 The circuit between nodes A and B in the middle constitutes the overall solution of the embodiment of the present invention—an application of parallel NTC resistors in switching converters. The principle is to use the temperature characteristics of the thermistor to m...

no. 2 example

[0045] The temperature compensation circuit of the output voltage feedback circuit of Embodiment 2 of the present invention uses a PTC resistor (also called a thermistor with a positive temperature coefficient) to perform temperature compensation on a negative temperature characteristic voltage regulator tube, such as Figure 5 shown. The circuit connection mode of this embodiment: the Figure 5 Node E in the middle is connected to the common node of resistor R12 and PTC resistor, and the common node of the other end of resistor R12 and PTC resistor is connected to the cathode of Zener tube ZD12, and then connected to node F through the anode of Zener tube ZD12. Will Figure 5 Circuit replacement between E and F nodes figure 1 The circuit between the nodes A and B constitutes the overall circuit solution of the second embodiment where the parallel PTC resistors are applied to the switching converter. The principle of the embodiment is as follows: the Zener diode ZD12 with a...

no. 3 example

[0047] The third embodiment of the present invention is to use the negative temperature characteristic of the forward conduction voltage drop of the diode to perform temperature compensation for the voltage regulator tube, such as Figure 6 shown. The connection relation of the circuit: the node G is connected with the anode of the switch diode D6, the cathode of the diode D6 is connected with the cathode of the voltage regulator ZD13, and the anode of the voltage regulator ZD13 is connected with the node H. use Figure 6 Circuit replacement between nodes G and H in figure 1 The circuit structure between the nodes A and B is the overall circuit principle diagram of the third embodiment of the present invention applied to the switching converter. The principle of the third embodiment is as follows: since the forward working diode itself has a negative temperature characteristic, the conduction threshold voltage of the diode decreases when the temperature rises. Therefore, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com