Die-cutting rule without eagle beak, manufacturing method and die-cutting plate applying die-cutting rule

A die-cutting knife and die-cutting board technology, which is applied in metal processing and other directions, can solve the problems of poor splicing of die-cutting knives and easy breakage of the olecranon, and achieve the effect of improving product quality, avoiding frequent knife changes and simple production methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

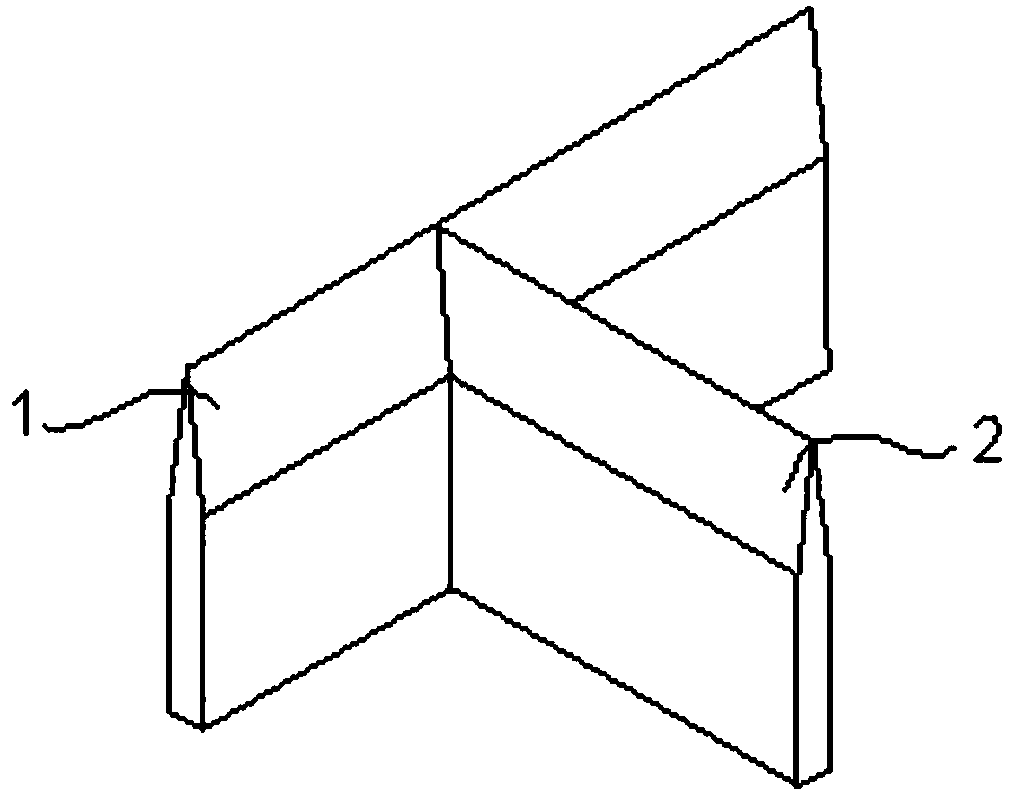

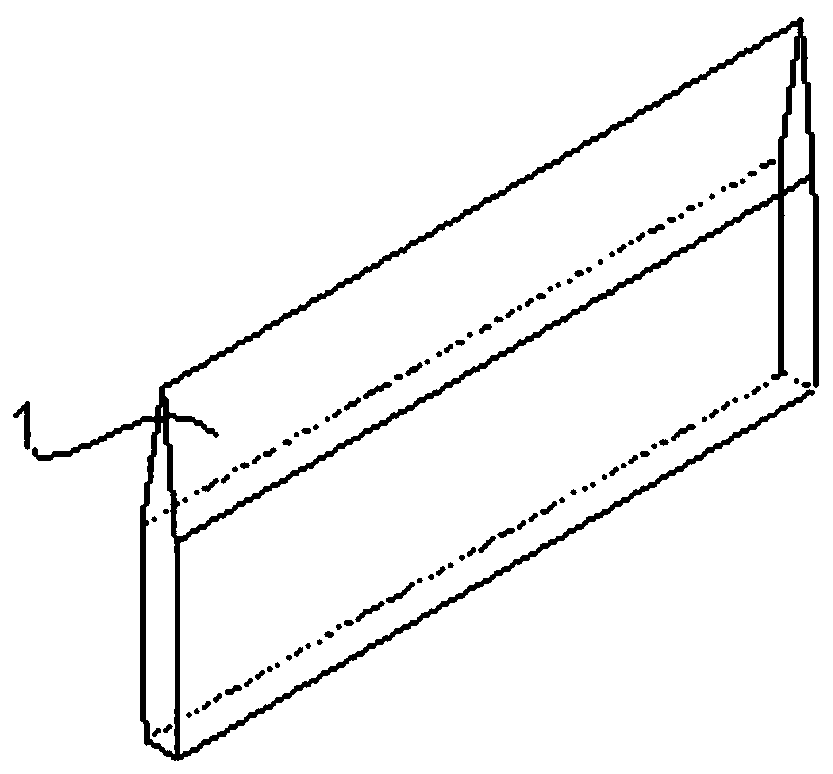

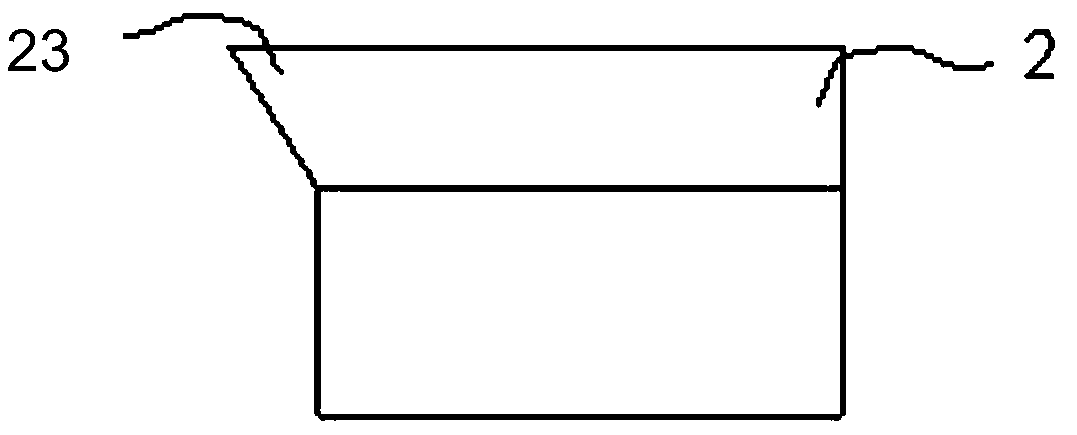

[0029] Figure 3 to Figure 6 A preferred embodiment of the olecranon-free die-cutting knife of the present invention is shown, which at least includes a first cutter 1 and a second cutter 2 used in conjunction, the first cutter 1 includes a first cutter body 11 and an upper part of the first cutter body 11 The first blade 12, the second cutter 2 includes a second cutter body 21 and the second blade 22 on the top of the second cutter body 21, at least one side of the first cutter 1 is provided with a vertical groove 13; the second cutter 2 The second cutter body 21 and the second blade 22 of at least one end of the second cutter body 21 are located on the same plane, and are all perpendicular to the length direction of the second cutter 2; the end of the second cutter 2 is inserted in the groove 13 so that connected. The die-cutter in this embodiment cancels the traditional olecranon design, and the splicing between the die-cutters adopts the method of positioning and slotting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com